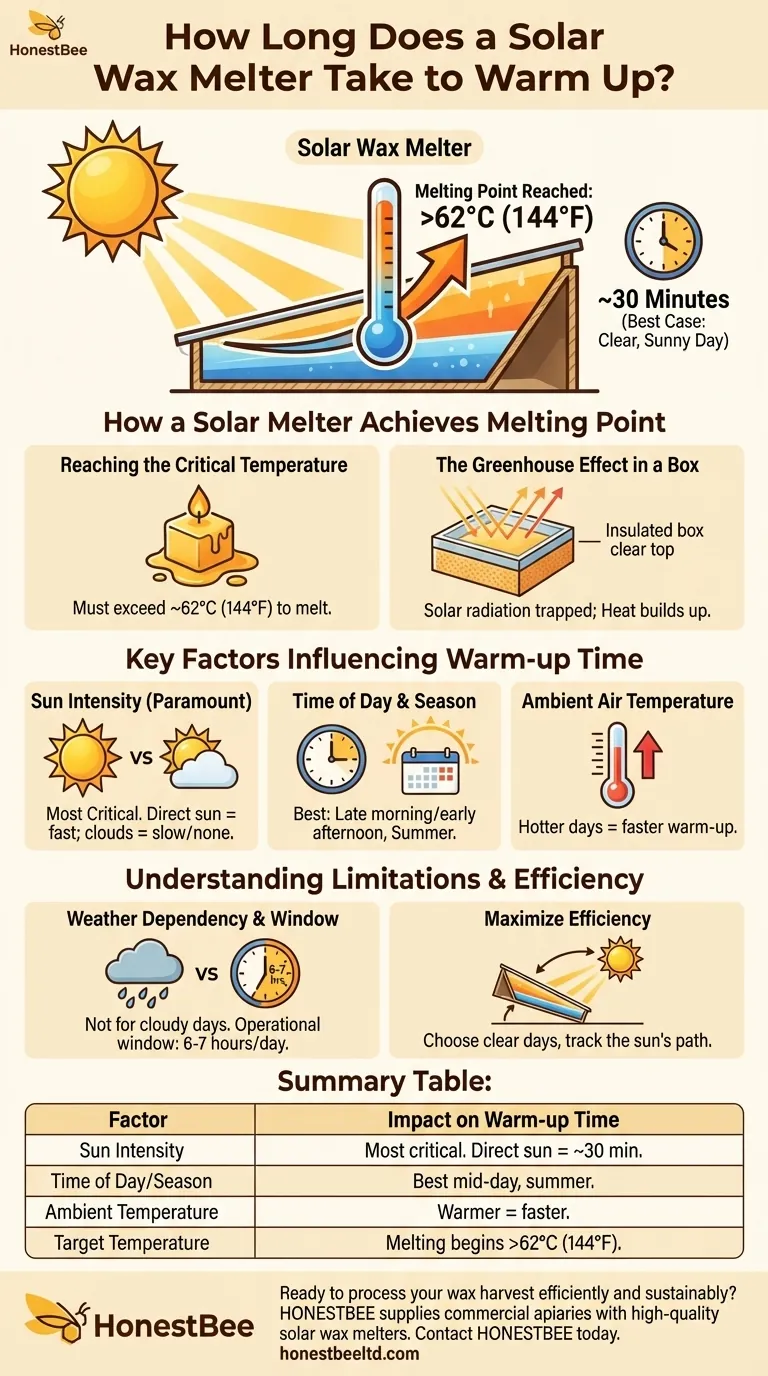

On a clear, sunny day, a Solar Wax Melter typically takes about 30 minutes to warm up sufficiently to begin melting wax. This process is entirely dependent on the melter reaching an internal temperature greater than 62°C (144°F), the melting point of beeswax.

The stated 30-minute warm-up time is a best-case scenario. Your actual results will be dictated by one primary factor: the intensity of the direct sunlight available.

How a Solar Melter Achieves Melting Point

A solar wax melter is a simple yet effective device designed to harness the sun's energy. Its performance is governed by basic thermal principles.

Reaching the Critical Temperature

The sole function of the melter is to create an environment that exceeds the melting point of beeswax. Scientific sources confirm this temperature is approximately 62°C (144°F). Until the internal collection chamber surpasses this threshold, no melting will occur.

The Greenhouse Effect in a Box

The melter works by trapping solar radiation. A clear top, typically glass or polycarbonate, allows sunlight to enter, while an insulated box minimizes heat loss. This captured energy steadily raises the internal temperature.

Key Factors Influencing Warm-up Time

The "30-minute" figure is a useful benchmark, but several environmental variables will directly impact the time it takes to reach operational temperature.

Sun Intensity is Paramount

The most critical factor is the strength and consistency of the sunlight. A clear, blue-sky day provides the direct radiation needed for a fast warm-up. Intermittent clouds will significantly slow the process, as the melter will lose heat during shaded periods.

Time of Day and Season

The angle of the sun affects the concentration of energy hitting the melter. Performance is best during late morning and early afternoon when the sun is highest in the sky. Likewise, summer months with more direct overhead sun will yield faster results than winter months.

Ambient Air Temperature

While less critical than direct sun, the outside air temperature plays a role. On a hot day, the melter has a higher starting point and loses less heat to the surrounding environment, contributing to a quicker warm-up.

Understanding the Limitations

The Solar Wax Melter is an excellent tool, but its effectiveness is bound by its reliance on the weather.

Absolute Weather Dependency

This device is not a "set and forget" appliance. It will not function on overcast, rainy, or heavily clouded days. Planning your wax processing requires checking the weather forecast.

The Operational Window

Even on an ideal day, the effective melting period is limited. The references indicate a productive window of 6 to 7 hours on a sunny day. This is the period when the sun is strong enough to maintain a temperature well above the wax's melting point.

How to Maximize Your Melter's Efficiency

To get the most out of your Solar Wax Melter, you must work with the environment, not against it.

- If your primary focus is processing a batch quickly: Plan to use the melter on a day with a forecast for clear, uninterrupted sun, starting it mid-morning.

- If your primary focus is maximizing a day's yield: Position the melter to face the sun directly and adjust its angle periodically to track the sun's path across the sky.

By understanding that the melter's performance is a direct reflection of the day's sunlight, you can plan effectively and achieve excellent results.

Summary Table:

| Factor | Impact on Warm-up Time |

|---|---|

| Sun Intensity | Most critical factor. Direct sun = fast warm-up (~30 min). Clouds = slow or no melting. |

| Time of Day/Season | Best performance mid-day and in summer when the sun is highest. |

| Ambient Temperature | Warmer days provide a higher starting point, speeding up the process. |

| Target Temperature | Melting begins once internal temperature exceeds 62°C (144°F). |

Ready to process your wax harvest efficiently and sustainably?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-focused beekeeping supplies. Our solar wax melters are designed for reliability and performance, helping you maximize your yield.

Contact HONESTBEE today to discuss your equipment needs and discover how our products can support your operation's success.

Visual Guide

Related Products

- Solar Beeswax Melter Easy Solar Wax Melter for Beeswax

- Electric Commercial Beeswax Melter for Factory Use

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- What role do surface heating pots and gas heating equipment play in beeswax recycling? Master On-Site Wax Purification

- How does beeswax extraction equipment contribute to the value of beekeeping by-products? Maximize Your Apiary's ROI

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What role does a high-precision digital temperature recorder play in the microwave beeswax extraction workflow?

- What are the technical advantages of using a solar wax melter? Master Premium Beeswax Extraction Today

- Why is it important to clean beeswax? Transform Raw Hive Wax into a Valuable Resource

- What is the melting point of beeswax? Essential Temperature Guide for Quality Wax Products

- How does the addition of oxalic or citric acid improve refined beeswax? Enhance Purity and Visual Brilliance