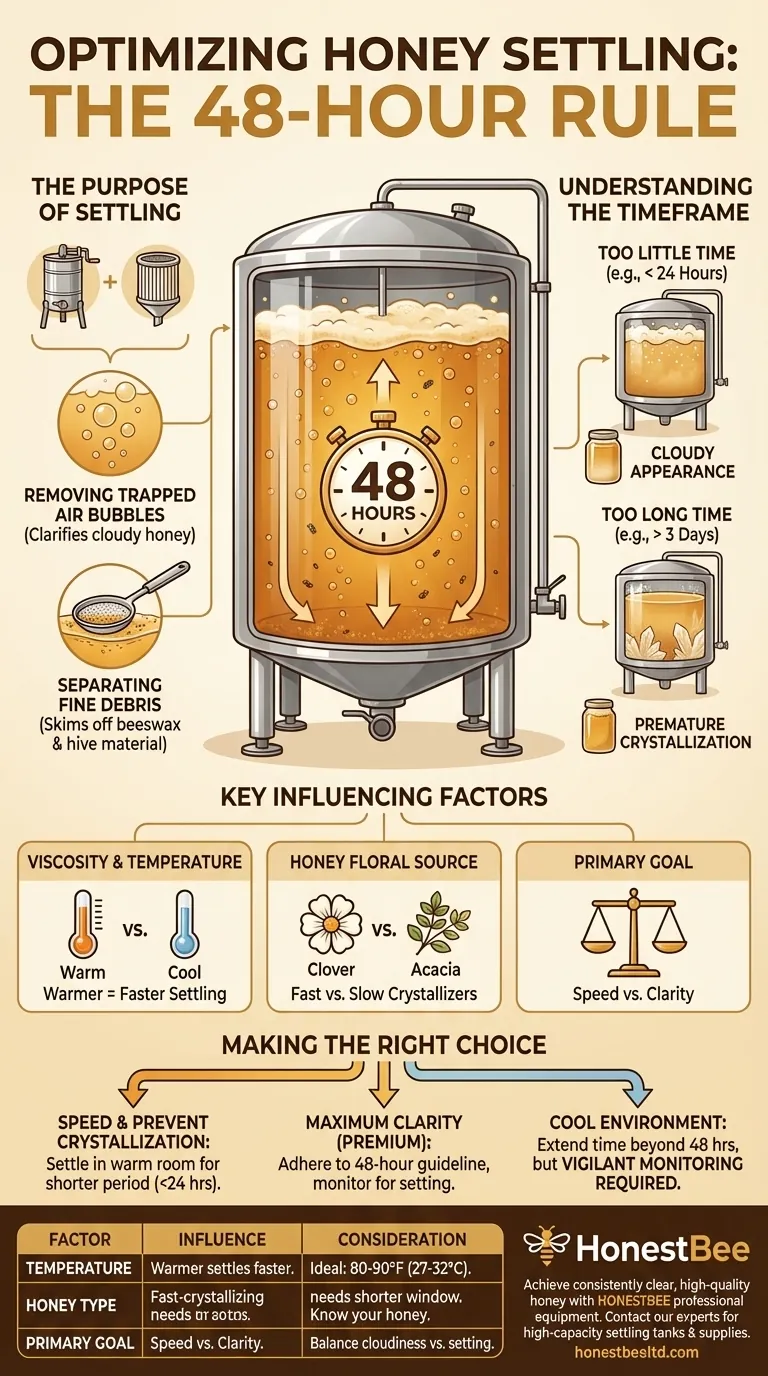

As a general rule, honey should be left to settle for approximately 48 hours. This two-day period is the industry standard for allowing fine air bubbles and wax particles to naturally rise to the surface, resulting in a clearer final product. Bottling sooner can leave the honey cloudy, while waiting longer introduces the risk of premature crystallization in the tank.

The goal of settling is to achieve maximum clarity by removing suspended air and debris. The 48-hour guideline represents a crucial balance between achieving this clarity and preventing the honey from beginning to crystallize before it can be bottled.

The Purpose of Settling Honey

Settling is a passive but critical step in honey processing that relies on gravity to clarify the product after the turbulence of extraction.

Removing Trapped Air Bubbles

The process of spinning honey out of the comb and pumping it into tanks introduces thousands of tiny air bubbles. These bubbles make the honey appear cloudy or milky. Letting the honey stand allows these less-dense bubbles to slowly rise to the top.

Separating Fine Debris

Small particles of beeswax or other hive material can also remain suspended after initial straining. The settling process gives these particles time to rise along with the air, forming a layer of scum on the surface that can be skimmed off before bottling.

Understanding the Optimal Timeframe

The 48-hour window is not arbitrary; it is based on the physical properties of honey and the risks associated with time.

The Risk of Settling for Too Little Time

If you bottle your honey after only 24 hours, especially if it is thick or the room is cool, many micro-bubbles will not have had time to rise. This will result in honey that looks cloudy in the jar and may develop a layer of foam at the top over time.

The Risk of Settling for Too Long

Honey is a supersaturated sugar solution, meaning it is naturally inclined to crystallize, or "set." Leaving it undisturbed in a tank for more than a few days provides the ideal conditions for this process to begin, making the honey difficult or impossible to bottle without reheating.

Key Factors That Influence Settling Time

While 48 hours is an excellent baseline, you may need to adjust based on your specific conditions. Your expert judgment is the most important tool.

Honey Viscosity and Temperature

The single most important factor is viscosity. Warmer honey is thinner (less viscous), allowing air bubbles to rise much faster. Settling honey in a warm room (80-90°F / 27-32°C) can significantly reduce the time needed. Conversely, cool honey is thick and may require more than 48 hours.

Honey's Floral Source

Different types of honey crystallize at vastly different rates. Honey high in glucose, like canola or clover, will set very quickly. Honey high in fructose, like tupelo or acacia, can remain liquid for years. Know your honey type and adjust your timeline accordingly.

The Trade-offs: Clarity vs. Crystallization

Processing honey always involves balancing competing priorities. Settling is a perfect example of this principle in action.

The Pursuit of Perfect Clarity

Achieving perfectly clear, bubble-free honey often requires patience and a longer settling period. This is the goal for honey competitions or high-end retail products where appearance is paramount.

The Danger of Premature Setting

The longer you wait for perfect clarity, the greater the risk that the honey begins to crystallize in your bulk tank. Dealing with a large volume of set honey is a significant challenge. The key is to find the point of "good enough" clarity for your needs before crystallization becomes a threat.

Making the Right Choice for Your Goal

Use the 48-hour rule as your starting point, but adapt it based on your environment and honey type.

- If your primary focus is speed and preventing crystallization: Settle the honey in a heated room for a shorter period, such as 24 hours, accepting that some micro-bubbles may remain.

- If your primary focus is maximum clarity for a premium product: Adhere to the 48-hour guideline, but monitor the tank for any signs of crystallization, especially if the honey is known to set quickly.

- If you are working in a cool environment without temperature control: You may need to extend the settling time beyond 48 hours, but you must be vigilant about the increased risk of the honey setting in the tank.

Ultimately, observing your honey's behavior is the definitive way to master the perfect settling time.

Summary Table:

| Factor | Influence on Settling Time | Key Consideration |

|---|---|---|

| Temperature | Warmer honey settles faster. | Ideal range: 80-90°F (27-32°C). Cooler temps may require more time. |

| Honey Type | Fast-crystallizing honey (e.g., clover) requires a shorter window. | Know your honey's crystallization tendency. |

| Primary Goal | Speed vs. Maximum Clarity. | Balance the risk of cloudiness with the risk of premature setting. |

Achieve consistently clear, high-quality honey with the right equipment. As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides durable, high-capacity settling tanks and other essential beekeeping supplies designed for professional operations. Let us help you optimize your entire processing workflow. Contact our experts today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Stainless Steel Honey Storage Tank with Lid for Honey

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Stainless Steel Uncapping Tank with Stand and Strainer

People Also Ask

- How does the depth of the honeycomb affect the choice of uncapping tool? Match the Right Gear for Maximum Efficiency

- What is the purpose of an uncapping tank and sieve system? Boost Honey Purity and Yield

- Why are large settling tanks used in the honey clarification process? Achieve Natural Purity & Batch Consistency

- What are the functional advantages of using a dedicated uncapping tank during honey processing? Maximize Your Honey Yield

- What is the purpose of a settling tank? Achieve Clear Water with Reliable Sedimentation

- What are the advantages of using a double uncapping tank? Maximize Honey Yield and Hive Harvest Efficiency

- What role does a honey settling tank play in the quality control of honey products? Ensure Premium Purity and Clarity

- Why is the configuration of a specialized uncapping bench necessary? Boost Efficiency and Reduce Waste