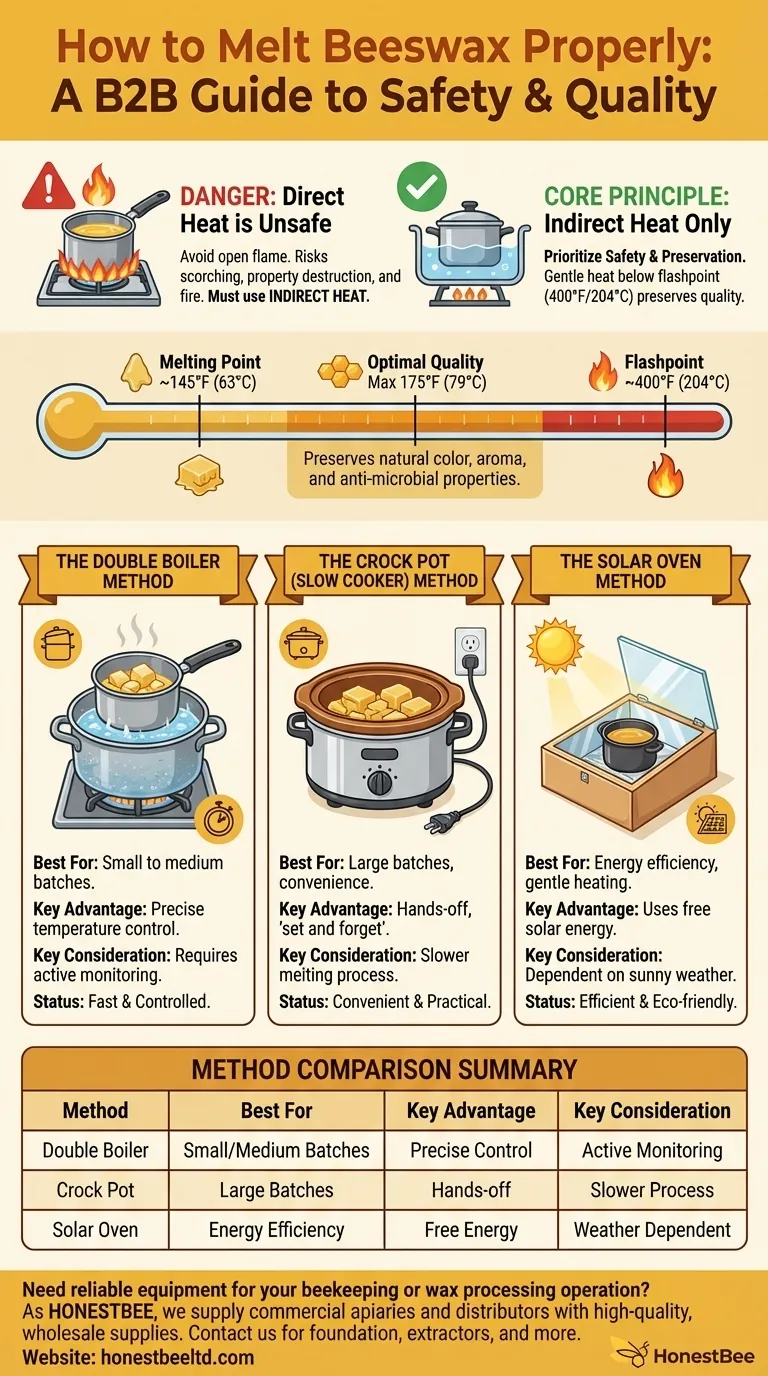

To melt beeswax properly, you must use a slow and controlled method of indirect heat. The most common and effective techniques are using a double boiler, a crock pot (slow cooker), or a solar oven. Direct heat from a stove or open flame is extremely dangerous and must be avoided, as it can easily scorch the wax, destroy its beneficial properties, and create a significant fire hazard.

The core principle of melting beeswax is not speed, but safety and preservation. Because beeswax is both flammable and sensitive to high temperatures, your goal is to heat it gently and indirectly, keeping it well below its flashpoint while preserving its natural color, aroma, and properties.

Why Indirect Heat is Non-Negotiable

Applying heat directly to a pan of beeswax is a common but critical mistake. Understanding the risks involved clarifies why indirect heating methods are the only responsible choice.

The Flammability Risk

Beeswax is a flammable material. While its melting point is low (around 145°F or 63°C), its flashpoint—the temperature at which its vapors can ignite—is approximately 400°F (204°C).

A pan placed on a direct heat source can easily reach this temperature, causing the wax to flare up and burn. Using a water bath, as with a double boiler or crock pot, naturally caps the temperature at the boiling point of water (212°F or 100°C), keeping it safely below the danger zone.

Preserving Wax Quality

Aggressive heating doesn't just pose a safety risk; it degrades the quality of the wax. To preserve its natural color, subtle honey aroma, and anti-microbial properties, you should not heat beeswax above 175°F (79°C).

Overheating can darken the wax and diminish its scent, which is especially important for projects like cosmetics, balms, or high-quality candles.

The Three Trusted Melting Methods

Each of these methods applies gentle, indirect heat, ensuring a safe process and a high-quality result. For any method, it is wise to use dedicated pots and utensils, as wax can be difficult to clean from kitchenware.

The Double Boiler Method

This classic technique offers excellent control and is ideal for small to medium batches.

You create a double boiler by placing a small pot or heatproof bowl containing the beeswax inside a larger pot filled with a few inches of water. The heat from the stove warms the water, which in turn gently melts the wax.

Never allow the water in the bottom pot to boil away completely, and monitor the process closely.

The Crock Pot (Slow Cooker) Method

This method is exceptionally convenient for larger batches and requires less active monitoring.

Simply place your beeswax into a dedicated slow cooker insert or a container placed inside the crock pot. You can add a small amount of water to the main basin to ensure even, gentle heating.

Set the crock pot to its "low" or "warm" setting and allow the wax to melt slowly over 1-2 hours, depending on the volume.

The Solar Oven Method

For the most energy-efficient and gentle approach, a solar oven is an excellent choice, though it is dependent on the weather.

Place the beeswax in a dark-colored, lidded container and position it inside the solar melter. The sun's heat is trapped, slowly melting the wax without any risk of scorching. A thermometer can help you monitor the temperature, and you can vent the lid slightly if it gets too hot.

Understanding the Trade-offs

Each method has unique advantages and disadvantages. Choosing the right one depends on your priorities, batch size, and available equipment.

Double Boiler: Control vs. Attention

The double boiler offers the most precise temperature control and is relatively fast. However, it requires constant attention to ensure the water level is safe and the wax doesn't overheat.

Crock Pot: Convenience vs. Time

A crock pot is the "set it and forget it" option, perfect for multitasking. Its primary drawback is that it's slower and offers less granular temperature control than a double boiler.

Solar Oven: Efficiency vs. Reliability

The solar oven uses free, renewable energy and is incredibly gentle on the wax. Its obvious limitation is its complete dependence on strong, consistent sunlight, making it unreliable for time-sensitive projects.

Making the Right Choice for Your Project

Your goal will determine the best method. Always prioritize safety by melting the wax slowly and never leaving it unattended.

- If your primary focus is small batches or maximum control: Use the double boiler method for its speed and precision.

- If your primary focus is convenience and larger volumes: The crock pot is the most practical and hands-off solution.

- If your primary focus is energy efficiency and you aren't on a deadline: A solar oven provides the gentlest heating at no energy cost.

Ultimately, melting beeswax successfully is a matter of patience and respecting the material's properties.

Summary Table:

| Method | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Double Boiler | Small to medium batches | Precise temperature control | Requires active monitoring |

| Crock Pot / Slow Cooker | Large batches, convenience | Hands-off, "set and forget" | Slower melting process |

| Solar Oven | Energy efficiency, gentle heating | Uses free solar energy | Dependent on sunny weather |

Need reliable equipment for your beekeeping or wax processing operation?

As HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale supplies needed for efficient and safe honey and wax production. From foundation to extractors, we provide the durable tools that help your business thrive.

Contact our team today to discuss your wholesale needs and discover how we can support your success.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- How to extract honey from wax? Crush and Strain vs. Melt and Separate

- What technology is used in the Solar Wax Melter to melt beeswax? Harnessing Sun-Powered Efficiency

- What is the technical function of applying melted raw wax? Master Olfactory Induction for Faster Beehive Colonization

- What are the key features of the electric double boiler for beeswax processing? Achieve Perfect, Safe Melting Every Time

- How do laboratory analysis and portable devices improve beeswax quality? The Ultimate Multi-Layered Quality Control Guide

- Why is specialized beeswax processing equipment vital for organic beekeeping? Secure Your Colony's Biological Integrity

- How does a professional steam wax melter optimize the recovery of beeswax? Maximize Yield & Hygiene for Your Apiary

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results