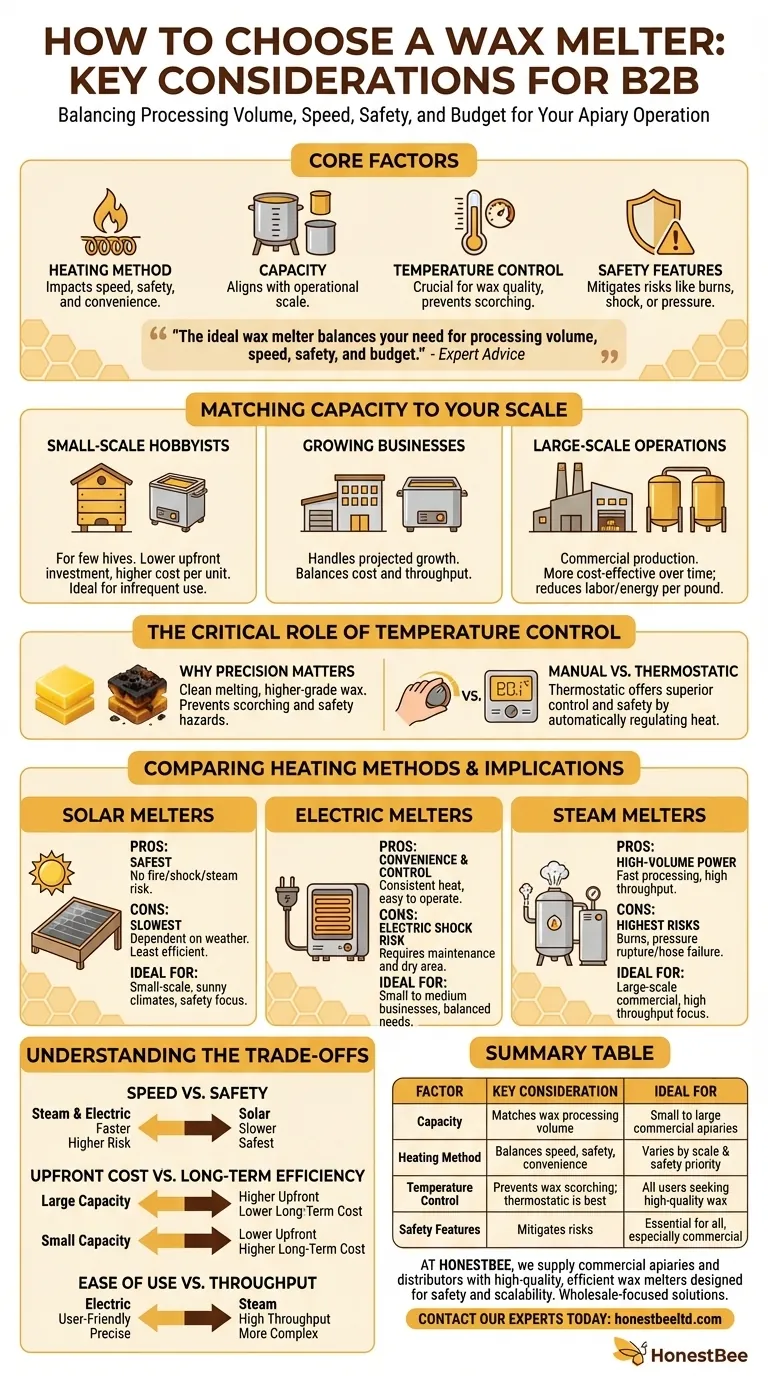

The most important factors when choosing a wax melter are its heating method, capacity, temperature control, and safety features. These elements directly impact your efficiency, the quality of your rendered wax, and your operational safety. The right choice will align with the scale of your operation, from a small hobbyist to a large-scale business.

The ideal wax melter is not the most expensive or powerful one, but the one that best balances your need for processing volume, speed, safety, and budget. Understanding the trade-offs between different heating methods is the key to making the right investment.

Matching Capacity to Your Scale

The size of your melter should correspond directly to the amount of wax you need to process. This is the first and most practical decision you will make.

For Small-Scale Hobbyists

A smaller capacity melter is often sufficient for hobbyists or beekeepers with only a few hives. While the cost per unit of wax may be higher, the lower upfront investment makes sense for infrequent use.

For Growing Businesses

If you are expanding your operation, consider a melter that can handle your projected growth. A mid-size unit offers a balance between cost and throughput, preventing an immediate need for another upgrade.

For Large-Scale Operations

For significant commercial production, larger melters are almost always more cost-effective. They process more wax in a single batch, reducing labor time and energy consumption per pound of wax.

The Critical Role of Temperature Control

Precise temperature is crucial for rendering high-quality wax efficiently without damaging it. Overheating can darken the wax and is a significant safety hazard.

Why Precision Matters

Maintaining a consistent, optimal temperature melts the wax cleanly from the cappings and comb without scorching it. This results in a cleaner, higher-grade final product and simplifies the filtering process.

Manual vs. Thermostatic Control

Some basic melters require manual temperature monitoring. Models with a built-in thermostat offer superior control and safety by automatically regulating the heat, preventing dangerous temperature spikes.

Comparing Heating Methods and Their Implications

The method used to heat the wax is the single biggest differentiator between models, affecting speed, safety, and convenience.

Solar Melters: Safety First

Solar melters use the sun's energy to gently melt wax. They are by far the safest option, with no risk of fire, burns from high-pressure steam, or electric shock.

However, their dependency on sunny weather makes them the least efficient and slowest method, suitable primarily for small-scale operators in appropriate climates.

Electric Melters: Convenience and Control

Electric melters offer excellent temperature control and are easy to operate. They provide a consistent heat source, making them a reliable and popular choice for small to medium-sized businesses.

The primary safety risk is a potential electric shock if the heating element is damaged or exposed to moisture. Always ensure the unit is well-maintained and used in a dry area.

Steam Melters: High-Volume Power

Steam generators are powerful and can process large quantities of wax quickly. They are ideal for large-scale beekeepers who need high throughput.

This power comes with significant safety risks. High temperatures can cause severe burns, and excessive pressure buildup in the steam generator can lead to a rupture or hose failure.

Understanding the Trade-offs

Choosing a wax melter involves balancing competing priorities. Being aware of these trade-offs is essential for making an informed decision.

Speed vs. Safety

The fastest methods (steam and electric) carry higher inherent risks of burns, pressure buildup, or electric shock. The safest method (solar) is also the slowest and most dependent on external conditions.

Upfront Cost vs. Long-Term Efficiency

While a large-capacity melter has a higher initial price, it delivers a lower cost per pound of processed wax over time. This makes it a more efficient long-term investment for a growing business.

Ease of Use vs. Throughput

Electric melters generally offer the best combination of user-friendliness and precise control. Steam melters provide the highest throughput but demand more attention to safety protocols and setup.

Making the Right Choice for Your Operation

Select your melter based on a clear understanding of your primary goal.

- If your primary focus is maximum safety and low-volume processing: A solar wax melter is the ideal choice.

- If your primary focus is balanced performance for a growing business: An electric melter with thermostatic control offers the best mix of speed, safety, and convenience.

- If your primary focus is high-volume, commercial-scale throughput: A steam wax melter is the most powerful option, provided you adhere strictly to safety procedures.

By aligning the melter's capabilities with your specific needs, you can ensure a safe, efficient, and valuable addition to your workflow.

Summary Table:

| Factor | Key Consideration | Ideal For |

|---|---|---|

| Capacity | Matches your wax processing volume | Small hobbyists to large commercial apiaries |

| Heating Method | Balances speed, safety, and convenience (Solar, Electric, Steam) | Varies by operational scale and safety priority |

| Temperature Control | Prevents wax scorching; thermostatic is best | All users seeking high-quality rendered wax |

| Safety Features | Mitigates risks of burns, electric shock, or pressure buildup | Essential for all operations, especially commercial |

Ready to choose the perfect wax melter for your apiary or distribution business?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-quality, efficient wax melters designed for safety and scalability. Our wholesale-focused operations ensure you get the right equipment to maximize your wax rendering efficiency and safety.

Contact our experts today to discuss your needs and discover how our solutions can benefit your operation.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- Why is precision temperature-controlled melting equipment required in beeswax purification? Protect Wax Quality

- What are the features of an electric wax melter? Gain Unmatched Control and Consistency

- What is the function of a wax stamper or wax presser? Maximize Value with Advanced Beeswax Refining Equipment

- What is an electric wax melter and how is it designed? Optimize Your Honey Processing Workflow

- What makes electric wax warmers an eco-friendly choice? A Cleaner, Safer Way to Scent Your Home

- What industrial problems are addressed by wax melting equipment? Eliminate Waste and Biological Risks Effectively

- What is the primary function of constant temperature water bath heating in beeswax purification? Optimize Wax Purity

- What function does a solar wax melter perform in the preparation of honeybee by-products like slumgum?