To melt beeswax using a dedicated wax melter, you simply place the wax into the pot, set the dial to a low or "warm" setting, and allow it to melt slowly over 30 to 90 minutes. The key is to use a controlled, low temperature and to never leave the process unattended, as beeswax is flammable and sensitive to high heat.

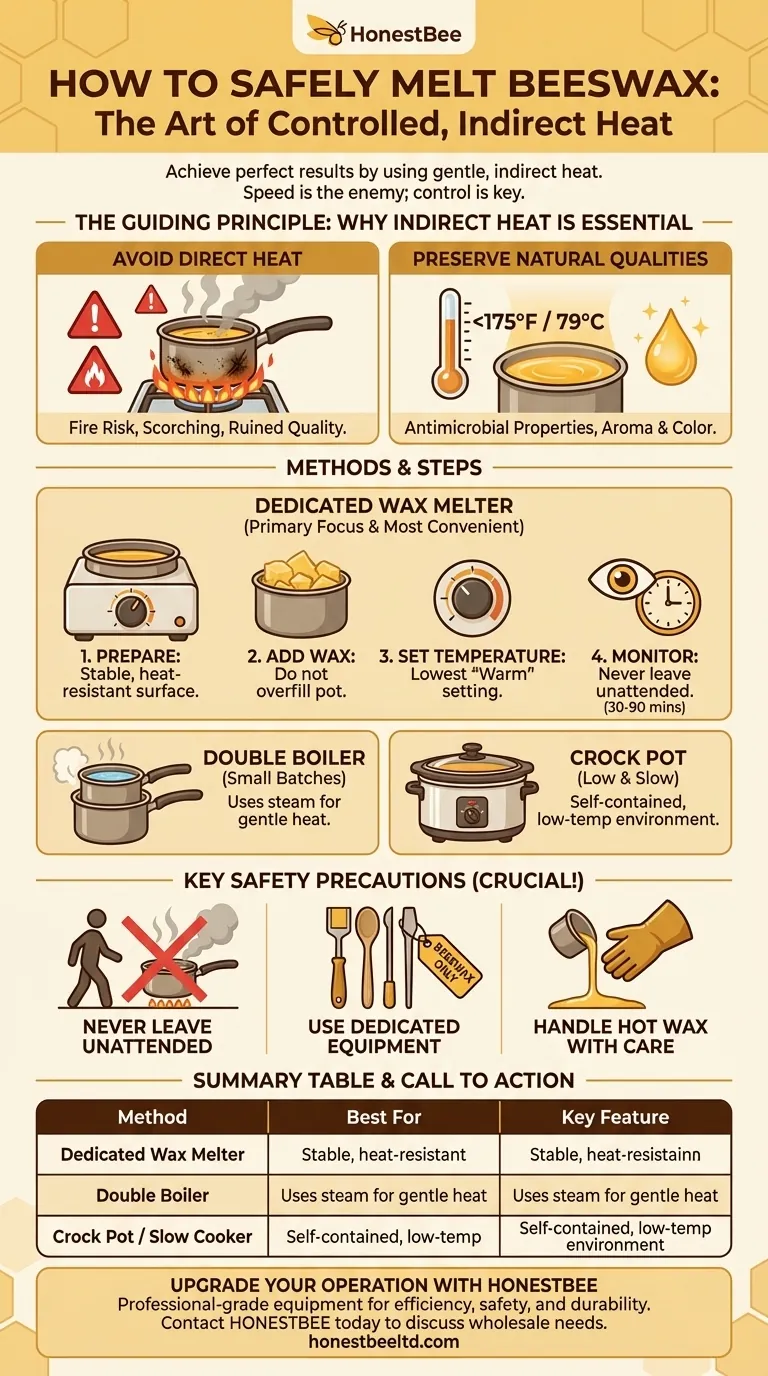

The central challenge in melting beeswax is not speed, but control. The goal is to apply gentle, indirect heat to liquefy the wax safely without scorching it, destroying its natural properties, or creating a fire hazard.

The Guiding Principle: Why Indirect Heat is Essential

Beeswax has a low flashpoint, meaning it can ignite if heated too quickly or to an excessive temperature. Applying heat directly from a stovetop or open flame is extremely dangerous.

The Dangers of Direct Heat

Direct heat creates hot spots that can easily scorch the beeswax. This not only ruins its color and aroma but can also raise its temperature past the point of combustion, creating a serious fire risk.

Preserving Natural Qualities

Beeswax contains natural antimicrobial properties that can be damaged by excessive temperatures. To preserve these beneficial qualities, the wax should ideally not be heated above 175°F (79°C). Gentle, indirect heat makes it far easier to stay within this safe range.

Using Your Equipment: Methods and Steps

While a dedicated electric melter is convenient, several methods follow the principle of indirect heat. The steps are similar across all of them: prepare, melt, and monitor.

Method 1: The Dedicated Wax Melter

This is the most straightforward tool for those who frequently work with wax.

- Preparation: Place your melter on a stable, heat-resistant surface. Ensure the melting pot is clean.

- Add Wax: Place your solid beeswax into the pot. Do not fill it past the maximum fill line or above the height of the pot's walls.

- Set Temperature: Turn the dial to the lowest possible setting, often labeled "warm." This ensures a slow, gentle melt.

- Monitor: Never walk away while the wax is melting. The process can take anywhere from 30 to 90 minutes, depending on the amount of wax.

Method 2: The Double Boiler

A double boiler is a classic and highly effective method for small to medium batches.

- Setup: Place a smaller pot (containing the beeswax) inside a larger pot that is partially filled with water. The water should surround the bottom of the inner pot but not be high enough to splash into it.

- Heat Gently: Bring the water in the outer pot to a gentle simmer over low to medium heat. The steam and hot water will indirectly heat and melt the wax in the inner pot.

- Monitor Water Level: Keep an eye on the water in the bottom pot to ensure it doesn't evaporate completely.

Method 3: The Crock Pot (Slow Cooker)

A crock pot acts as a self-contained, low-temperature heating environment.

- Setup: Place a heat-safe container, like a glass Mason jar or a dedicated pouring pot, inside the crock pot. Place the solid beeswax inside this container.

- Add Water: Pour a few inches of water into the crock pot, around the base of the container holding the wax.

- Heat on Low: Set the crock pot to its "low" setting and cover it. The wax will melt slowly and safely over a couple of hours.

Key Safety Precautions and Trade-offs

Successfully melting beeswax means prioritizing safety and quality over speed. Ignoring these factors can lead to poor results or dangerous accidents.

Never Leave Melting Wax Unattended

This is the most important rule. A distraction can lead to the wax overheating, smoking, and potentially igniting. Always stay present and monitor the process from start to finish.

Use Dedicated Equipment

Beeswax is difficult to clean from pots and utensils once it hardens. To avoid contaminating kitchenware and simplify cleanup, designate a specific set of tools exclusively for your wax-related projects.

Handle Hot Wax with Care

Melted beeswax is extremely hot and can cause severe burns. Always use heat-resistant gloves and pour the liquefied wax into appropriate, heat-safe molds or containers.

Choosing the Right Method for Your Goal

Your ideal method depends on the scale and frequency of your projects.

- If your primary focus is occasional hobby use or small batches: The double boiler or crock pot method is inexpensive, safe, and highly effective.

- If your primary focus is processing raw wax from a beehive: A solar melter is an excellent, energy-free choice for clarifying large amounts of comb.

- If your primary focus is efficiency for a small business or frequent candle making: A dedicated electric wax melter offers the best combination of control, convenience, and capacity.

Ultimately, mastering the art of melting beeswax is about embracing a slow, controlled, and observant process.

Summary Table:

| Method | Best For | Key Feature |

|---|---|---|

| Dedicated Wax Melter | Frequent use, small businesses | Built-in temperature control, convenient |

| Double Boiler | Small to medium batches, hobbyists | Uses steam for gentle, indirect heat |

| Crock Pot / Slow Cooker | Small batches, low and slow melting | Self-contained, safe heating environment |

Upgrade your beekeeping operation with professional-grade equipment from HONESTBEE.

Whether you're a commercial apiary scaling up production or a distributor seeking reliable wholesale supplies, our wax melters and beekeeping equipment are built for efficiency, safety, and durability. Let us help you streamline your process and protect your valuable beeswax.

Contact HONESTBEE today to discuss your wholesale needs and discover the right equipment for your business.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What is the core value of efficient wax melting equipment? Maximize Quality and Biosecurity in Beeswax Processing

- What is the procedure for refining beeswax using the Bain-marie method? Master High-Purity Wax Processing

- How do professional beekeeping wholesalers support beeswax testing equipment? Key Ways Distribution Drives Innovation

- What is the ideal temperature for melting beeswax in the bain-marie? Achieve Perfect, High-Quality Results

- What methods are used to melt and clarify beeswax cappings? Commercial Techniques for High-Quality Refinement

- What is the process for filtering beeswax? A Guide to Clean, Pure Wax for Any Project

- How can the solar waxing machine be adjusted for optimal performance? Master Solar Tracking for Maximum Wax Melting

- What are the internal components of a solar waxer? Unlock Simple, Pure Wax Production