The safest and most effective way to melt beeswax is to use indirect, gentle heat. The two recommended methods are a double boiler, which you can create with standard kitchen equipment, or a dedicated electric wax melter. Direct heat, such as placing a pot of wax straight onto a stove burner, is extremely dangerous as it can easily overheat the wax to its flashpoint and cause a fire.

The core principle of melting beeswax is control. Because it is a natural and flammable material, you must use a slow and steady indirect heat source to liquefy it safely without scorching it or creating a fire hazard.

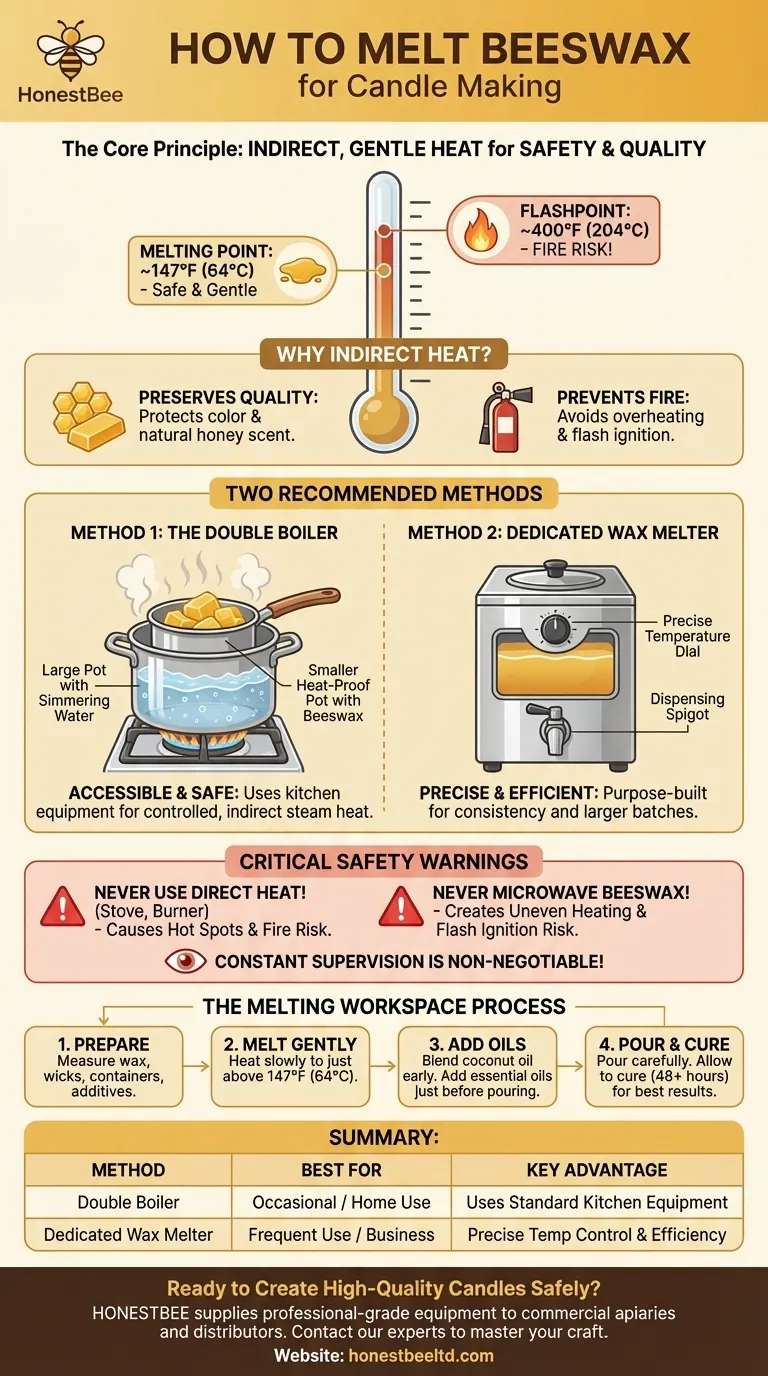

Why Indirect Heat is Critical for Beeswax

Understanding the properties of beeswax is the key to melting it correctly. It has a relatively low melting point but is also flammable at higher temperatures, a gap that direct heat can bridge dangerously fast.

The Melting Point vs. The Flashpoint

Beeswax begins to melt at approximately 147°F (64°C). This is the temperature you are trying to gently exceed.

However, its flashpoint—the temperature at which its vapors can ignite if exposed to a flame—is around 400°F (204°C). A stove's electric coil or gas flame can easily create hot spots in a pot that far exceed this temperature, creating a significant fire risk.

Preserving Wax Quality

Beyond safety, gentle heat preserves the integrity of the beeswax. Overheating or scorching the wax can darken its color and destroy its subtle, natural honey-like scent, which is one of its most desirable qualities.

The Two Recommended Melting Methods

Both of these methods are built around the principle of indirect heat, ensuring a safe and controlled melt.

Method 1: The Double Boiler

This is the most accessible and common method for home candle makers. You are not buying a special tool, but creating one.

To set up a double boiler, you need a large pot and a smaller, heat-proof pouring pot or bowl that can rest on the rim of the larger pot without touching the bottom.

Simply fill the larger pot with a few inches of water and bring it to a gentle simmer over medium heat. Place your beeswax in the smaller pot and set it over the simmering water. The steam, not the direct flame, will gently melt the wax.

Method 2: The Dedicated Wax Melter

For those who plan to make candles more frequently or in larger batches, a dedicated wax melter is an excellent investment.

These are purpose-built appliances, often made of stainless steel, that feature a precise temperature dial and a spigot at the bottom. This allows you to melt the wax to a specific temperature and easily dispense it into your candle containers with minimal mess.

Understanding the Trade-offs and Safety Hazards

Your choice of method is less important than your adherence to safety principles. Mishandling flammable wax is a serious risk that is easily avoided.

The Danger of Direct Heat

Never place a pot containing beeswax directly on an electric or gas burner. This method provides intense, uneven heat that makes temperature control nearly impossible. It is the primary cause of wax fires.

Why You Must Never Use a Microwave

Microwaving beeswax is incredibly dangerous. Microwaves heat unevenly, creating super-heated pockets within the wax that can flash ignite. Furthermore, many candle-making pouring pots are metal, which should never be placed in a microwave.

Constant Supervision is Non-Negotiable

Melting wax is not a "set it and forget it" task. Regardless of your method, you must remain present and attentive throughout the entire process. A pot of hot wax should never be left unattended.

How to Apply This to Your Project

Follow these steps for a successful and safe melting process.

- Prepare Your Workspace: Before you begin melting, have everything ready. This includes your measured beeswax (pellets melt faster than blocks), candle containers with wicks secured, and any additives like coconut oil or essential oils.

- Melt Gently: Using your double boiler or wax melter, slowly bring the wax temperature just above its 147°F melting point. Stir occasionally with a bamboo skewer or silicone spatula to ensure it melts evenly.

- Add Oils Correctly: If you are blending your beeswax with other oils like coconut oil, you can add them at the beginning of the melting process. However, wait to add essential oils until the wax is fully melted and removed from the heat, just before you pour. This prevents the delicate scents from burning off.

- Pour and Cure: Carefully pour the melted wax into your prepared container. Let the candle sit undisturbed until it is fully hardened. For the best scent throw and burn quality, allow your beeswax candle to "cure" for at least 48 hours to a week before lighting it.

Making the Right Choice for Your Goal

Your approach should match your ambition and commitment to the craft.

- If your primary focus is making a few candles for personal use: The double boiler method is perfectly safe, effective, and requires no special equipment.

- If your primary focus is starting a candle-making hobby or small business: Investing in a dedicated wax melter will provide far greater consistency, safety, and efficiency.

- If your primary focus is absolute safety: Always use indirect heat, never walk away from melting wax, and keep a fire extinguisher rated for Class B (flammable liquid) fires nearby.

Mastering the melt is the first step to creating beautiful, natural beeswax candles safely in your own home.

Summary Table:

| Method | Best For | Key Advantage |

|---|---|---|

| Double Boiler | Occasional/Home Use | Uses standard kitchen equipment |

| Dedicated Wax Melter | Frequent Use/Business | Precise temperature control & efficiency |

Ready to create high-quality beeswax candles safely and efficiently?

Whether you're a hobbyist or a commercial apiary, having the right equipment is crucial for success. HONESTBEE supplies professional-grade beekeeping supplies and candle-making equipment to commercial apiaries and distributors through our wholesale-focused operations.

We can provide you with the reliable tools you need to master your craft. Contact our experts today to discuss your specific needs and discover how we can support your beekeeping and candle-making goals.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How do you pour melted beeswax into a mold? A Step-by-Step Guide for a Flawless Finish

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers