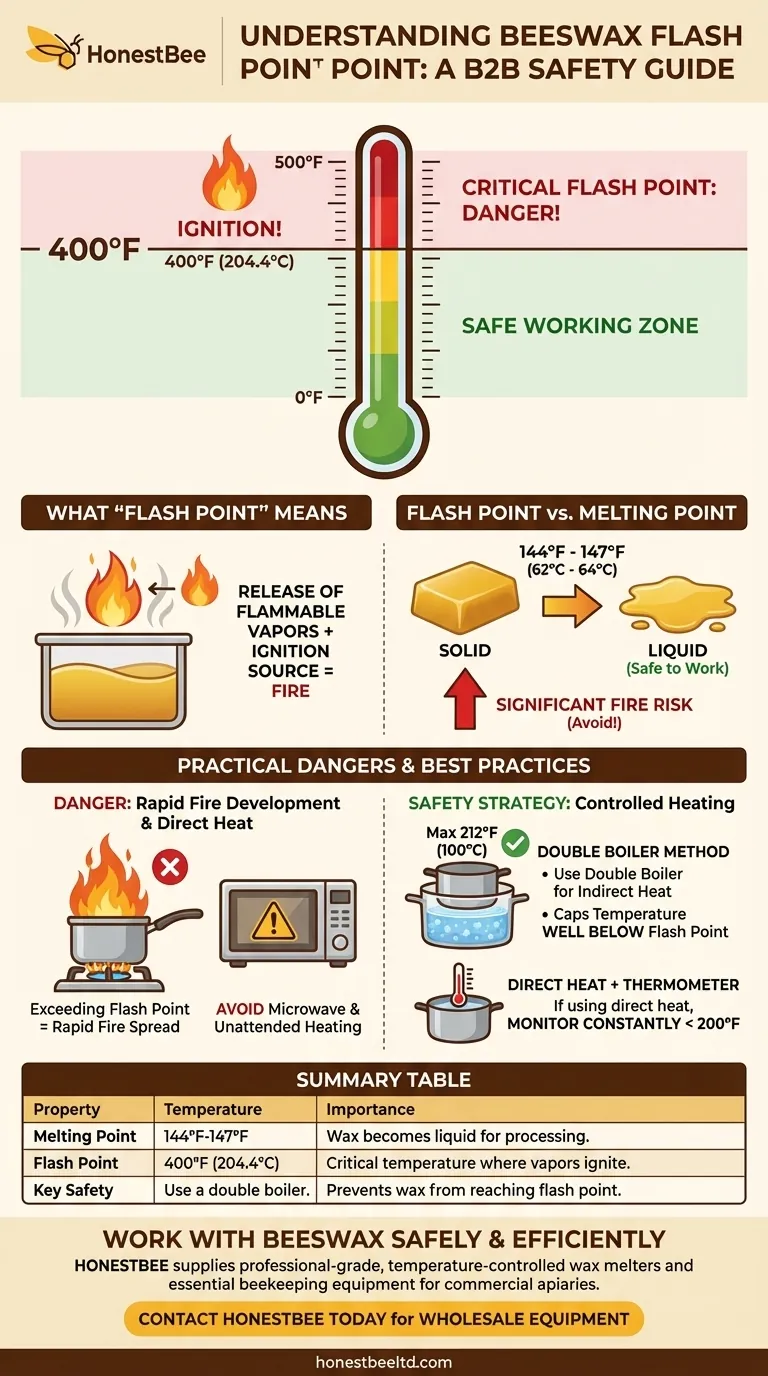

From a technical standpoint, the flash point of beeswax is approximately 400°F (204.4°C). This is the critical temperature at which the wax produces enough flammable vapor to ignite in the presence of an open flame or spark. Understanding this property is not just a piece of trivia; it is the cornerstone of handling beeswax safely in any application.

The core issue isn't that beeswax is inherently dangerous, but that the process of melting it can become hazardous if not properly controlled. Exceeding its flash point transforms a stable solid into a significant fire risk, making temperature management the single most important safety principle.

What "Flash Point" Actually Means

The Ignition of Vapors

The flash point is not the temperature at which beeswax spontaneously combusts. Rather, it's the point where it releases a sufficient concentration of flammable vapors into the air. If an ignition source is present—like a gas stove flame or an electrical spark—these vapors can flash into a brief, intense fire.

Flash Point vs. Melting Point

It is crucial to distinguish the flash point from the melting point. Beeswax typically melts between 144°F and 147°F (62°C to 64°C), becoming a liquid that is easy to work with. There is a very wide, safe temperature margin between its melting point and its flash point of 400°F. The goal is to work entirely within this range.

The Practical Dangers of Exceeding the Flash Point

Rapid Fire Development

Once the flash point is reached, a fire can start and spread with surprising speed. A small, unattended pot of overheating beeswax can quickly become a dangerous, self-sustaining fire.

The Risk is in the Process

The danger isn't with a solid block of beeswax or a finished candle. The risk is concentrated entirely in the melting phase, when you are actively applying heat. This is why all safety protocols are focused on how you heat the wax.

Best Practices for Safe Melting

To mitigate these risks, the strategy is simple: use a heating method that makes it difficult or impossible to reach 400°F.

The Double Boiler Method

The safest and most recommended method for melting beeswax is a double boiler. By placing the wax in a container that sits in a larger pot of simmering water, you use the water to transfer heat indirectly. Because water boils at 212°F (100°C), this method naturally caps the temperature of the wax well below its flash point.

Direct Heat Requires Strict Monitoring

If you must use direct heat (like an electric hot plate), using a thermometer is non-negotiable. Constantly monitor the temperature to ensure it remains in a safe range, ideally below 200°F, which is more than sufficient for melting.

Common Pitfalls to Avoid

Never attempt to melt beeswax in a microwave. The uneven heating can create super-heated "hot spots" that can quickly exceed the flash point while other parts of the wax are still solid. Likewise, never leave melting wax unattended, even for a moment.

Applying This to Your Project

Your choice of heating method should be guided by your specific goals and scale.

- If your primary focus is hobbyist creation (candles, lip balms): Use the double boiler method; it is the most reliable and foolproof way to ensure safety without needing specialized equipment.

- If your primary focus is larger-scale production: Invest in a dedicated, temperature-controlled wax melter to guarantee precise, consistent, and safe heating.

- If your primary focus is any application, large or small: The universal principle is to always use indirect, controlled heat and never allow the wax temperature to approach its 400°F flash point.

By understanding and respecting this fundamental property, you can work with beeswax safely and confidently.

Summary Table:

| Property | Temperature | Importance |

|---|---|---|

| Melting Point | 144°F - 147°F (62°C - 64°C) | Wax becomes liquid for processing. |

| Flash Point | 400°F (204.4°C) | Critical temperature where flammable vapors ignite. |

| Key Safety Practice | Use a double boiler or temperature-controlled melter. | Prevents wax from reaching dangerous flash point. |

Work with Beeswax Safely and Efficiently

For commercial apiaries and distributors, safe wax handling is non-negotiable. HONESTBEE supplies professional-grade, temperature-controlled wax melters and other essential beekeeping equipment designed for safety and efficiency at scale.

Contact HONESTBEE today to discuss your wholesale equipment needs and ensure your operation meets the highest safety standards.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What type of beeswax should be used for processing? Choose Wax Caps for Pure Results and Colony Health

- How does efficient beeswax processing equipment contribute to production? Unlock High-Value Purity and Market Success

- What industrial problems are addressed by wax melting equipment? Eliminate Waste and Biological Risks Effectively

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What determines the choice of method for melting beeswax? Optimize Your Wax Processing Efficiency

- What types of beeswax melters are available for beekeepers? Choose the Right One for Your Operation

- What is the process for melting and rendering beeswax with a double boiler? Master the Safe Extraction Method

- What energy source does a Solar Wax Melter utilize? Harness Free Solar Power for Your Apiary