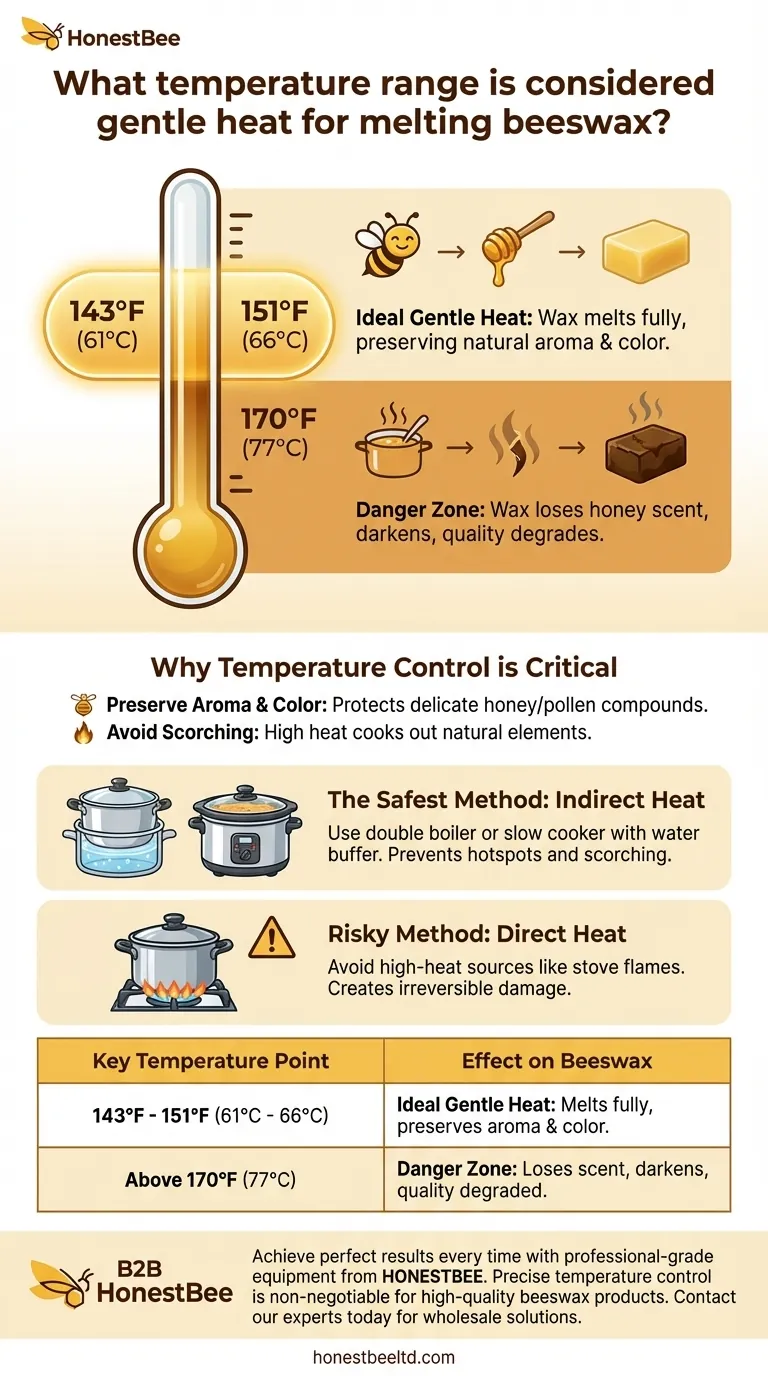

The ideal temperature for gently melting beeswax is between 143°F and 151°F (61°C to 66°C). Heating beeswax beyond this narrow window, especially past 170°F (77°C), will cause it to lose its distinct aroma and darken in color, degrading its natural quality.

Controlling temperature is not just about melting the wax; it's about preserving the delicate properties that make beeswax valuable. The goal is to apply just enough heat to change its state from solid to liquid without damaging its composition.

Why Temperature Control is Critical for Beeswax

Working with beeswax requires precision. Unlike other substances, its quality is directly tied to the heat it's exposed to during the melting process. Understanding this relationship is key to achieving a high-quality result.

The Ideal Melting Point

Beeswax begins to melt right around 143°F (61°C). The range up to 151°F (66°C) represents the sweet spot where the wax becomes fully liquid and workable without sustaining any damage.

The "Danger Zone" for Quality

Once the temperature of the wax exceeds 170°F (77°C), you enter a danger zone. At this point, the heat begins to break down the volatile compounds responsible for the wax's signature honey-like scent.

Continued heating at these higher temperatures will also cause the wax to darken in color, shifting from a pleasant yellow or cream to a dull, brownish hue.

Preserving Natural Properties

The gentle aroma and golden color of beeswax come from natural esters and compounds from honey and pollen. Aggressive or excessive heat effectively "cooks" these delicate elements out of the wax, permanently altering its character.

Understanding the Trade-offs and Risks

Choosing the right heating method is crucial for avoiding common pitfalls. The primary mistake is applying heat too quickly or too directly.

The Risk of Direct Heat

Never place a pot of beeswax directly on a high-heat source like a gas flame or electric stovetop. This creates intense hotspots that will scorch the wax it touches, instantly exceeding the 170°F limit and creating a fire hazard.

The Consequence of Overheating

The damage from overheating is irreversible. Once the aroma is gone and the color has darkened, you cannot restore the wax to its original state. This results in a lower-quality product, which is especially problematic for applications like cosmetics, balms, or high-end candles.

The Safest Method: Indirect Heat

The safest and most reliable way to melt beeswax is with indirect heat. A double boiler, or a slow cooker (crockpot) with water in the basin, creates a water bath. This uses the water as a buffer, ensuring the wax is heated gently and can never get hotter than the water's boiling point, preventing scorching.

Making the Right Choice for Your Goal

Your approach to melting beeswax should align with your intended outcome.

- If your primary focus is preserving maximum aroma and color: Use a double boiler or a thermostatically controlled wax melter, and monitor the temperature closely to keep it under 151°F.

- If your primary focus is safety and simplicity: The slow cooker method is excellent. Place your wax in a container inside the crockpot, add water to the pot, and set it to "low" for a slow, gentle melt.

- If you must use direct heat: Use the absolute lowest setting on your stove, check the temperature constantly with a thermometer, and remove the wax from the heat as soon as it's melted.

Ultimately, patience is the key to melting beeswax correctly and preserving its beautiful natural properties.

Summary Table:

| Key Temperature Point | Effect on Beeswax |

|---|---|

| 143°F - 151°F (61°C - 66°C) | Ideal Gentle Heat: Wax melts fully while preserving its natural aroma and color. |

| Above 170°F (77°C) | Danger Zone: Wax loses its honey-like scent and darkens in color; quality is degraded. |

Achieve perfect results every time with professional-grade equipment from HONESTBEE.

Whether you are a commercial apiary or a beekeeping equipment distributor, precise temperature control is non-negotiable for producing high-quality beeswax products. Our wholesale-focused supplies, including thermostatically controlled wax melters and safe heating solutions, are designed to help you preserve the valuable properties of your beeswax efficiently and at scale.

Ready to enhance your production quality and consistency? Contact our experts today to discuss your specific needs and discover the right equipment for your operation.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- Why are specialized magnetron cooling fans critical? Ensure Long-Term Reliability for Beeswax Extraction

- What are the characteristics of the wax tray in a solar wax melter? Master Your Wax Reclamation Today

- What equipment is recommended for a makeshift beeswax double boiler? Safe DIY Wax Melting Guide

- What is the role of temperature-controlled heating equipment in the recovery and processing of beeswax? - Pure Results

- How does a solar wax melter improve the processing of beeswax in an apiary? Boost Purity and Lower Energy Costs

- What is the recommended heating process for wax vats? Master Foundation Sheet Production Today

- What are three common methods for melting beeswax? Master Safe & Efficient Wax Processing

- What temperature should beeswax not exceed to avoid discoloration? Preserve Color & Aroma with Proper Heating