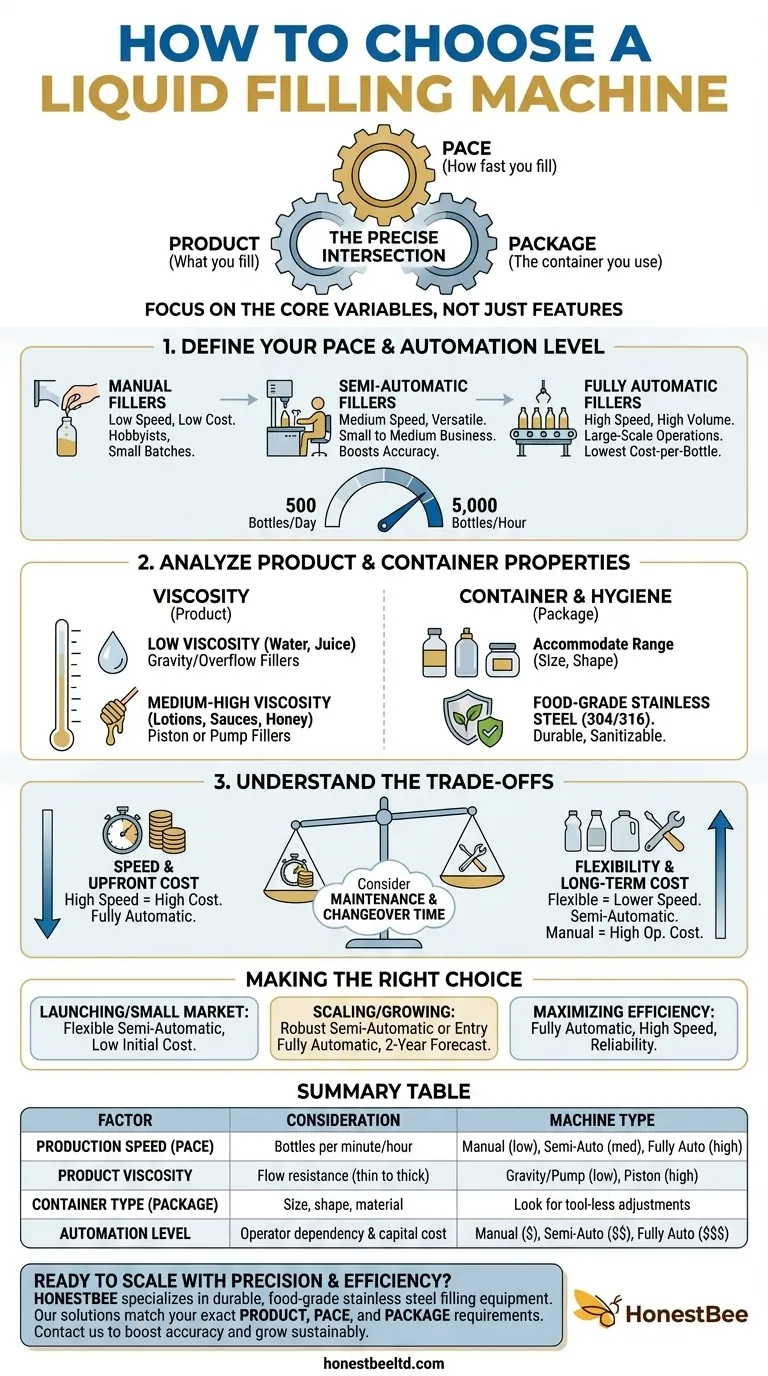

To choose the right liquid filling machine, you must move beyond features and focus on three core variables: your product's properties (like viscosity), your required production speed, and the containers you intend to fill. The ideal machine is not the one with the most functions, but the one that aligns perfectly with these operational realities and your specific business goals.

The decision is not about buying a piece of equipment; it is an investment in your production capacity. The key is to find the precise intersection of your Product (what you fill), your desired Pace (how fast you fill), and your Package (the container you use).

Start with Your Production Goals (The Pace)

Before evaluating any hardware, you must first quantify your operational needs. This single step will narrow your options more effectively than any other.

Defining Your Required Fill Rate

Your target fill rate—measured in bottles per minute (BPM) or per hour (BPH)—is the most critical starting point. This metric determines the necessary level of automation.

Are you filling 500 bottles a day or 5,000 per hour? Be realistic about your current demand and projected growth over the next 1-3 years.

Choosing the Right Level of Automation

Your fill rate directly dictates the appropriate level of automation for your budget and scale.

- Manual Fillers: Best for hobbyists, product development, or extremely small batches. They are inexpensive but slow and operator-dependent, leading to inconsistent fills.

- Semi-Automatic Fillers: The ideal starting point for most small to medium-sized businesses. They require an operator to place containers and activate the fill cycle but offer a significant boost in speed and accuracy over manual methods.

- Fully Automatic Fillers: Essential for large-scale operations. These machines integrate into a conveyor line, handling everything from container feeding to filling and capping with minimal human intervention. They represent a major capital investment but deliver the lowest cost-per-bottle at high volumes.

Analyze Your Product and Container (The Product & Package)

The physical properties of your liquid and the design of your container impose strict technical constraints on the machine's design.

The Critical Role of Viscosity

Viscosity—a liquid's resistance to flow—is a primary technical consideration. A machine designed for water-thin liquids will fail to fill thick honey or cream.

- Low Viscosity (e.g., water, juice): Gravity fillers or overflow fillers are effective and economical.

- Medium to High Viscosity (e.g., lotions, sauces, honey): You will need a machine with more power, such as a piston filler or a pump filler, which can actively force the product into the container.

Material Compatibility and Hygiene

The materials the machine is constructed from are non-negotiable, especially for food, beverage, or pharmaceutical products.

Always look for food-grade stainless steel (like 304 or 316) for all contact parts. This ensures the machine is durable, corrosion-resistant, and can be properly sanitized to prevent contamination.

Accommodating Your Container's Size and Shape

Consider the full range of bottles or jars you plan to use. A machine must be able to handle your smallest and largest containers.

Look for versatility. Good semi-automatic and fully automatic machines offer simple, tool-less adjustments for changing container height and diameter, as well as adjustable fill volumes.

Understanding the Trade-offs

Choosing a filling machine involves balancing competing priorities. Being aware of these trade-offs is key to making a sound investment.

Speed vs. Flexibility

There is often a direct trade-off between speed and flexibility. Fully automatic lines are incredibly fast for one specific bottle and product but can require significant downtime and complex changeover procedures for new jobs.

Semi-automatic systems are slower but vastly more flexible, often allowing an operator to switch from a small jar to a large bottle in minutes.

Upfront Cost vs. Long-Term Operational Cost

A manual filler has a negligible upfront cost but a very high long-term operational cost due to labor and inconsistency.

A fully automatic machine has a massive upfront cost but delivers the lowest possible cost-per-fill at scale. A semi-automatic machine sits in the middle, balancing capital investment with improved efficiency.

The Hidden Costs: Maintenance and Changeover

Ease of cleaning is a critical factor in total cost of ownership. A machine that is difficult to disassemble and sanitize can add hours of unproductive labor to each production day.

Evaluate the changeover time—the time it takes to switch from one product or container to another. In a high-mix, low-volume environment, long changeover times can eliminate any speed advantage the machine offers.

Making the Right Choice for Your Business

Your selection should be a direct reflection of your business strategy. Use these guidelines to zero in on the best solution for your goals.

- If your primary focus is launching a new product or serving a small market: Prioritize a flexible semi-automatic machine with low initial cost and easy changeovers.

- If your primary focus is scaling a growing business: Invest in a robust, high-end semi-automatic or an entry-level fully automatic machine that can meet your current demand and your 2-year growth forecast.

- If your primary focus is maximizing efficiency in a large-scale operation: The only choice is a fully automatic system designed for high speed, reliability, and minimal operator involvement.

Ultimately, the right machine is the one that solves today's problem without creating a new one tomorrow.

Summary Table:

| Factor | Consideration | Machine Type |

|---|---|---|

| Production Speed (Pace) | Bottles per minute/hour | Manual (low), Semi-Auto (medium), Fully Auto (high) |

| Product Viscosity | Flow resistance (thin to thick) | Gravity/Pump (low), Piston (high) |

| Container Type (Package) | Size, shape, material | Look for tool-less adjustments for versatility |

| Automation Level | Operator dependency & capital cost | Manual ($), Semi-Auto ($$), Fully Auto ($$$) |

Ready to scale your liquid filling operations with precision and efficiency? HONESTBEE specializes in supplying durable, food-grade stainless steel filling equipment to commercial apiaries and beekeeping distributors. Whether you're scaling honey production or managing high-viscosity products, our wholesale-focused solutions are engineered to match your exact Product, Pace, and Package requirements. Contact us today to discuss how our equipment can boost your fill accuracy, reduce operational costs, and grow your business sustainably.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- What benefits do industrial automated filling machines provide for honey? Scale Your Production with Precision

- What is the primary role of specialized honey-filling machines in commercial beekeeping operations? Scaling Efficiency.

- For what type of honey is a gravity filling machine best suited? Optimize Your Bottling for Low-Viscosity Honey

- How are honey stick packs formed from the cut film strips? Master the Precision of Forming Tube Technology

- What causes inconsistent fill volumes in a honey stick machine? Expert Troubleshooting Guide

- How do industrial honey-filling machines impact beekeeping operations? Enhance Hive Health & Operational Efficiency

- How do industrial-grade beehive manufacturing and honey-filling machinery convert ecological value? | HONESTBEE

- What is the best way to pack honey? Preserve Quality and Manage Crystallization