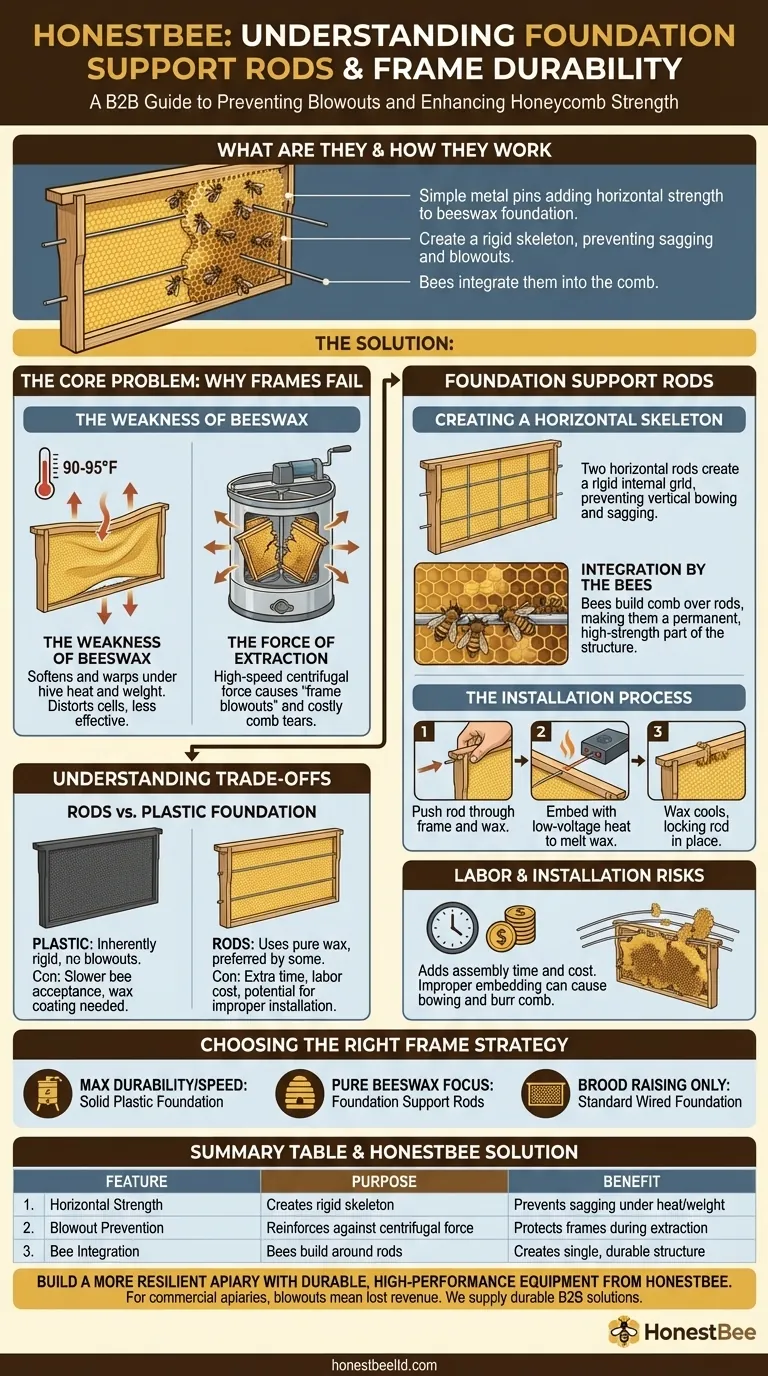

At their core, foundation support rods are simple metal pins used to add horizontal strength to beeswax foundation within a beehive frame. They work by creating a rigid skeleton inside the wax sheet, preventing it from sagging under heat and weight or blowing apart during honey extraction. Bees then build their comb directly over and around these rods, integrating them into a single, durable structure.

The real purpose of foundation support rods is not just to add strength, but to act as insurance against "frame blowouts"—the catastrophic failure of honeycomb inside a honey extractor. They are a targeted solution for beekeepers who choose to use traditional beeswax foundation and want to ensure their frames can withstand the rigors of honey harvesting.

The Core Problem: Why Frames Fail

To understand the value of support rods, you must first understand the structural weaknesses of a standard beehive frame. The entire system is subject to heat, weight, and significant physical force.

The Weakness of Beeswax

Beeswax is a remarkable material, but it becomes soft and pliable at the temperatures normally found inside a bustling hive (90-95°F / 32-35°C).

A new sheet of wax foundation, especially when weighed down by a heavy cluster of bees, can easily stretch, sag, or warp. This results in distorted honeycomb cells that are less effective for raising brood or storing honey.

The Force of Extraction

The most common point of failure is during honey harvesting. A honey extractor is a centrifuge that spins frames at high speed to sling the honey out of the cells.

This process exerts immense outward force on the comb. If the comb is not perfectly attached to all four sides of the frame or has been weakened by sagging, it can tear away from the foundation or even explode, a costly and messy event known as a "blowout."

How Foundation Support Rods Provide a Solution

Support rods directly counteract the primary forces that lead to frame failure. They are typically used with "crimp wire" foundation, which already has vertical wires embedded, creating a robust internal grid.

Creating a Horizontal Skeleton

By installing two thin, stainless steel rods horizontally through the sheet of foundation, you create a rigid internal skeleton.

These rods prevent the vertical wires from bowing and stop the entire sheet of wax from sagging downwards or stretching outwards.

Integration by the Bees

Bees are incredibly efficient builders. When they encounter a support rod, they don't work around it; they incorporate it directly into the "midrib" of the new honeycomb.

This makes the rod a permanent, central part of the finished comb, dramatically increasing its tensile strength and resistance to tearing.

The Installation Process

The process is straightforward. The sharp point of the rod is pushed through one side of the wooden frame, passes through the wax foundation, and exits the other side.

For best results, the rod must then be embedded into the wax. This is typically done by passing a low-voltage electrical current through the rod, heating it just enough to melt the surrounding wax, which then cools and hardens around it, locking it in place.

Understanding the Trade-offs

While effective, support rods are just one of several methods for creating durable frames. Choosing the right one depends on your goals and beekeeping philosophy.

Rods vs. Plastic Foundation

The most common alternative is to use solid plastic foundation instead of wax. Plastic is inherently rigid, will not sag, and is almost completely immune to blowouts during extraction.

However, many beekeepers find that bees are slower to draw comb on plastic foundation, and it must be coated with a layer of beeswax to encourage acceptance. Others simply prefer to keep their hives free of plastic.

The Cost of Time and Labor

Using support rods is an extra step that adds time and a small cost to the process of assembling frames. For a beekeeper managing hundreds or thousands of hives, this added labor can be significant.

Potential for Improper Installation

If the rods are not embedded properly, they can bow outwards from the foundation. This can interfere with correct bee space, causing the bees to build unwanted burr comb between frames and making inspections more difficult.

Choosing the Right Frame Strategy

Your decision should be based on how you intend to use the frames and your overall management style.

- If your primary focus is maximum durability and extraction speed: Solid plastic foundation is often the most efficient choice, virtually eliminating the risk of blowouts.

- If your primary focus is using pure beeswax foundation: Installing foundation support rods is a critical and highly effective step to protect your frames, comb, and honey harvest.

- If you are primarily raising brood and not extracting from those frames: Standard wired foundation without extra support rods is usually sufficient, as these frames are not subjected to centrifugal force.

By understanding the forces at play within the hive, you can build a more resilient and productive apiary.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Horizontal Strength | Creates a rigid skeleton inside wax foundation | Prevents sagging under heat and weight |

| Blowout Prevention | Reinforces comb against centrifugal force | Protects frames during honey extraction |

| Bee Integration | Bees build comb around the rods | Creates a single, durable structure |

Build a more resilient apiary with durable, high-performance equipment from HONESTBEE.

For commercial apiaries and distributors, frame blowouts and comb failure mean lost time and lost revenue. Our wholesale-focused operations supply the durable beekeeping supplies and equipment you need to maximize productivity and protect your honey harvest.

Contact HONESTBEE today to discuss your wholesale needs and ensure your frames are built to last.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Professional 500g Sectional Comb Honey Frame System for Beekeeping

People Also Ask

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- How do fully automatic wax foundation machines benefit beekeepers? Boost Efficiency & Scale Your Apiary

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation