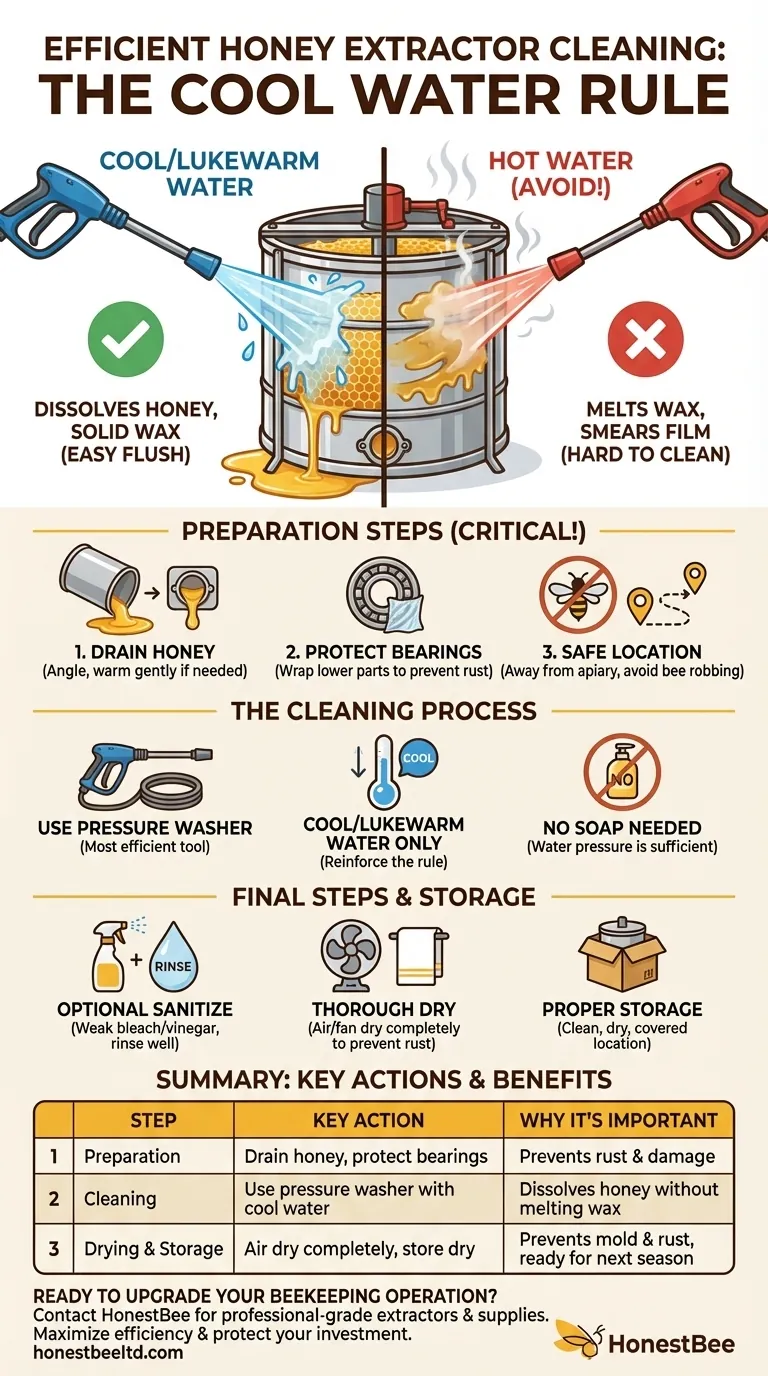

Efficiently cleaning a honey extractor comes down to a simple, counterintuitive rule: use cool water, not hot. The most effective method involves using a pressure washer or high-pressure hose with cool or lukewarm water to dissolve the honey without melting and smearing the small bits of beeswax. This allows you to quickly flush away the residue, protect your equipment, and prepare it for storage.

The core objective is not to achieve a sterile, factory-new shine, but to remove the vast majority of honey and wax residue efficiently. This prevents mold, fermentation, and contamination of future harvests while protecting the extractor's mechanical components from damage.

The Preparatory Steps: Setting Up for a Clean Wash

Before you even introduce water, a few preparatory actions will make the entire process significantly easier and safer for your equipment.

Drain All Excess Honey

First, ensure you've drained as much honey as possible from the extractor. Tip it on an angle to let the last bits pool and drip from the honey gate.

For thick, crystallized honey that won't drain, you can gently warm the extractor. A home-brew heating belt or pad wrapped around the drum overnight works well without creating excessive heat.

Protect the Bearings

This is the most critical step for preserving your extractor's lifespan. Water, especially from a pressure washer, can damage the lower bearings.

Before washing, cover any exposed lower bearings and the shaft with plastic cling wrap to create a watertight seal. This simple action prevents rust and premature wear.

Choose the Right Location

Never leave your extractor outside for the bees to "clean." While it sounds natural, this can incite a robbing frenzy among hives and rapidly spread diseases like American Foulbrood.

Choose a washing location away from your apiary, such as a driveway or wash bay, where the sugary runoff won't attract bees.

The Core Cleaning Process: From Sticky to Spotless

With preparation complete, you can move on to the actual washing. The key is using the right tools and, most importantly, the right water temperature.

The Power of Water Pressure

A small pressure washer or a hose with a high-pressure nozzle is the most efficient tool for this job.

The force of the water physically dislodges honey and small flakes of wax from the drum walls and basket without the need for scrubbing or chemicals.

The Critical Role of Water Temperature

Use cool or lukewarm water, never hot. This is the most common mistake beekeepers make.

Hot water (above 120°F or 49°C) melts beeswax. Instead of washing away, the melted wax smears into a thin, waxy film that is extremely difficult to remove once it cools. Cool water dissolves the honey but keeps the wax flakes solid so they can be easily flushed out.

To Soap or Not to Soap?

Avoid using soap or detergents. It is very difficult to rinse away all the soap residue, which can contaminate your next honey harvest with unwanted flavors or chemicals.

Water pressure alone is almost always sufficient. If you feel you must use a cleaner, rinse the extractor multiple times with extreme thoroughness.

Understanding the Common Pitfalls

Avoiding a few common mistakes is just as important as following the correct procedure. These errors can make the job harder or even harm your bees.

The "Bee Cleaning" Risk

As mentioned, letting bees clean your equipment is a significant biosecurity risk. It habituates bees to robbing and can quickly transfer mites and diseases between colonies. Always clean your equipment manually in a controlled location.

The Hot Water Mistake

It is worth repeating: hot water is your enemy when cleaning an extractor. It turns a simple washout into a frustrating chore by creating a stubborn wax film that requires scraping to remove.

The Goal is "Clean," Not "Sterile"

Don't stress about getting the machine back to a "like-new" condition. Tiny specks of wax or a slight honey sheen on the stainless steel are perfectly acceptable.

The primary goal is to remove enough organic matter to prevent mold and fermentation during storage. Anything that doesn't come out after a thorough pressure washing probably won't affect your next harvest.

Final Steps: Drying and Storage

Properly drying and storing your extractor ensures it's ready for immediate use next season and prevents rust or damage.

The Optional Sanitizing Rinse

For extra peace of mind, some beekeepers perform a final rinse with a very weak bleach or vinegar solution to sanitize the surfaces. If you do this, follow it with a final clean water rinse.

Ensuring a Thorough Dry

Dry the extractor completely to prevent rust, especially around bearings and non-stainless steel parts. Let it air dry in a warm, sunny spot or use a fan to speed up the process. Towel dry any areas that hold water.

Storing for Next Season

Once completely dry, store the extractor in a clean, dry location. Covering it with a tarp or its original box will keep it free of dust and pests until you need it again.

Matching Your Method to Your Goal

Your approach can be tailored slightly depending on your equipment and priorities.

- If your primary focus is maximum speed: A pressure washer with cool water is your best tool for removing honey and wax in minutes.

- If you are cleaning without a pressure washer: Use a hose with a jet nozzle, soft cloths, and a spatula, then add a few gallons of cool water to the drum and spin to wash the basket.

- If your primary focus is equipment longevity: Always protect the lower bearings with plastic wrap before washing and ensure the unit is completely dry before storage.

A clean, well-maintained extractor is your key to a smooth and successful harvest year after year.

Summary Table:

| Step | Key Action | Why It's Important |

|---|---|---|

| Preparation | Drain honey, protect bearings with plastic wrap. | Prevents rust and mechanical damage. |

| Cleaning | Use a pressure washer with cool/lukewarm water. | Dissolves honey without melting wax for easy removal. |

| Drying & Storage | Air dry completely, store in a dry location. | Prevents mold and rust, ensures readiness for next season. |

Ready to upgrade your beekeeping operation with professional-grade equipment?

A clean, well-maintained honey extractor is essential for a smooth harvest. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, high-performance extractors and a full range of beekeeping supplies through our wholesale-focused operations.

Let us help you maximize efficiency and protect your investment. Contact our team today to discuss your needs and discover how our equipment can benefit your business.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- What is the necessity of 1:2 ratio bevel gears in manual honey extractors? Optimize Extraction Speed and Efficiency

- What type of honey extractor is best? Maximize Your Harvest Efficiency with the Right Choice

- What are the differences between manual and automatic honey extractors? Choose the Right Tool for Your Apiary

- What tips can maximize honey extraction efficiency? Unlock Higher Yields and Purer Honey