The primary advantages of a semi-automatic filling machine are its unique combination of enhanced production speed, operational versatility, and a cost-effective price point. This equipment acts as the crucial intermediate step between laborious manual filling and a high-cost, fully automated line. It allows growing businesses to significantly increase their output and product consistency without the prohibitive capital investment of a fully automated system.

Semi-automatic fillers represent the optimal balance for growing businesses. They offer a substantial upgrade in speed and precision over manual methods while retaining the flexibility to handle diverse products and containers, all at a manageable price point.

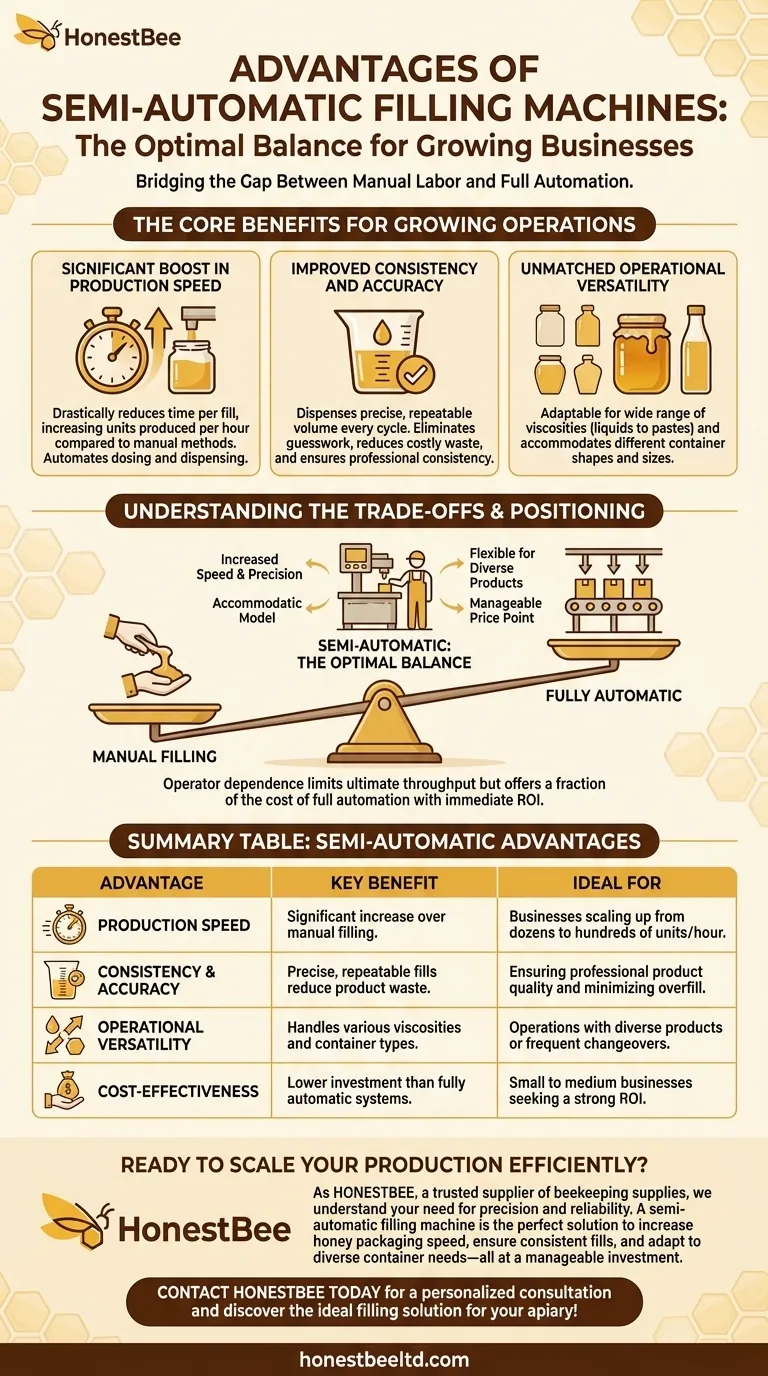

The Core Benefits for Growing Operations

A semi-automatic machine introduces precision and mechanization to the most critical part of the packaging process: the fill. This delivers immediate, measurable improvements over a purely manual workflow.

A Significant Boost in Production Speed

While an operator is still required to place containers and initiate the fill cycle, the machine automates the dosing and dispensing of the product. This simple change drastically reduces the time per fill, allowing for a significant increase in the number of units produced per hour compared to filling by hand.

Improved Consistency and Accuracy

These machines are engineered to dispense a precise, repeatable volume of product with every cycle. This eliminates the guesswork and variability of manual filling, reducing costly product waste and ensuring a professional, consistent final product for your customers.

Unmatched Operational Versatility

One of the most valued characteristics of semi-automatic fillers is their adaptability. They can be quickly configured to handle a wide range of product viscosities, from thin liquids to thick pastes, spreads, and honey. Furthermore, they easily adjust to accommodate different container shapes and sizes.

Understanding the Trade-offs: Semi-Automatic vs. Fully Automatic

To truly understand the value of a semi-automatic machine, it's essential to see where it fits between manual labor and a fully automated line. Its advantages are defined as much by what it is as by what it is not.

The Human Element: Operator Dependence

The "semi-automatic" nature means a human operator is an integral part of the process. This reliance on an operator to stage containers and trigger the machine inherently limits the ultimate throughput compared to a fully automatic system that integrates conveyors and requires no intervention per cycle.

Scalability and Throughput Limits

Semi-automatic fillers are perfect for moving from dozens to hundreds of containers per hour. However, operations that require filling thousands of containers per hour will quickly exceed their capacity. For mass production, a fully automatic line is necessary for its superior speed and scalability.

The Cost-Benefit Analysis

This is the defining trade-off. A semi-automatic machine costs a fraction of a fully automatic system. For a small or medium-sized business, this makes it an accessible investment that delivers an immediate and substantial return by increasing efficiency and reducing labor costs.

Making the Right Choice for Your Production Goals

Deciding on a filling machine requires aligning the equipment's capabilities with your specific business needs and future goals.

- If your primary focus is moving beyond manual filling on a limited budget: A semi-automatic machine provides the best return on investment by dramatically increasing speed and consistency.

- If your primary focus is product diversity and frequent changeovers: The versatility and adaptability of a semi-automatic filler are ideal for handling various products and container types without major downtime.

- If your primary focus is maximizing throughput for a high-volume, uniform product: A fully automatic system is the superior choice, despite the higher initial cost, to meet demanding production targets.

Ultimately, the right semi-automatic filler empowers your business to scale efficiently by bridging the critical gap between manual labor and full automation.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Production Speed | Significant increase over manual filling | Businesses scaling up from dozens to hundreds of units/hour |

| Consistency & Accuracy | Precise, repeatable fills reduce product waste | Ensuring professional product quality and minimizing overfill |

| Operational Versatility | Handles various viscosities and container types | Operations with diverse products or frequent changeovers |

| Cost-Effectiveness | Lower investment than fully automatic systems | Small to medium businesses seeking a strong ROI |

Ready to Scale Your Production Efficiently?

As HONESTBEE, a trusted supplier of beekeeping supplies and equipment for commercial apiaries and distributors, we understand the precision and reliability your operation demands. A semi-automatic filling machine is the perfect solution to increase your honey and product packaging speed, ensure consistent fills, and adapt to your diverse container needs—all at a manageable investment.

Let us help you bridge the gap between manual labor and full automation. Our wholesale-focused operations ensure you get the right equipment to meet your production goals.

Contact HONESTBEE today for a personalized consultation and discover the ideal filling solution for your apiary!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

People Also Ask

- What is the function of honey extraction and filling machinery in nomadic beekeeping? Optimize Your Processing Hub

- How does production volume affect the selection of a honey packaging machine? Choose the Right Automation Level

- In what way does professional honey-filling equipment ensure the purity of the final product? Maintain Residue-Free Quality

- How does an automatic honey-filling machine ensure quality? From Raw Forest Honey to Commercial Success

- How does the implementation of automated honey-filling machines address the challenge of rising production costs? Achieve Scalability and Precision

- What is the importance of professional honey filling and storage equipment for maintaining honey quality and potency?

- What is the recommended yearly maintenance for a honey stick machine? Optimize Your Production & Extend Equipment Life

- How does the use of professional automated honey-filling machines benefit urban honey production? Scale Your Apiary