For serious honey production, the Langstroth hive is the undisputed industry standard. Its primary advantages are its modular design, which allows for virtually unlimited expansion, and its standardization, which enables the use of highly efficient, large-scale honey extraction equipment. This combination makes it uniquely suited for maximizing honey yield.

The choice of a beehive is a choice of an entire system. The Langstroth hive is the cornerstone of a system designed for high-volume honey production, but this efficiency comes with specific requirements for equipment and labor.

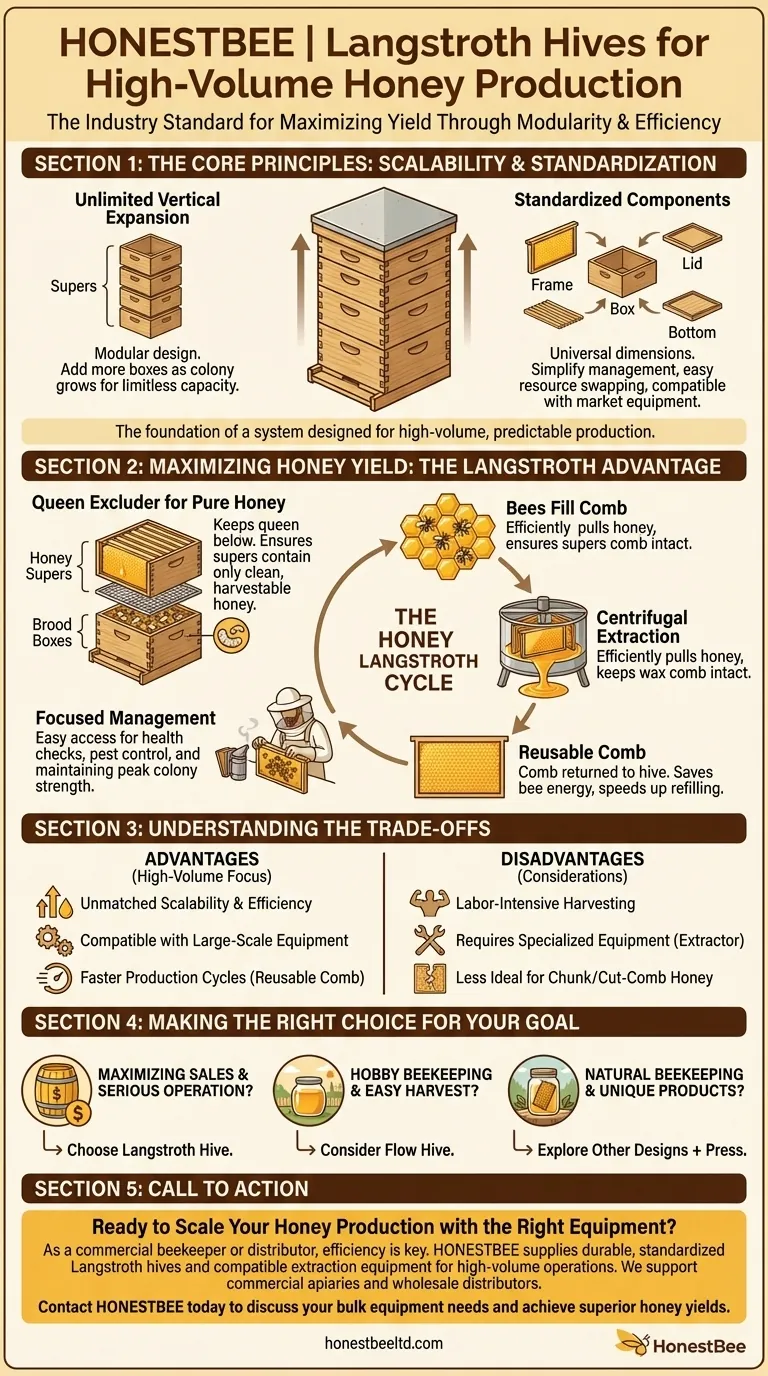

The Core Principle: Scalability and Standardization

The Langstroth hive's design, dating back to the 1850s, was revolutionary because it introduced predictable, manageable space. This core concept is what drives its production advantages.

Unlimited Vertical Expansion

The hive consists of a series of stackable boxes, known as "supers." As a bee colony grows and brings in more nectar, the beekeeper can simply add more boxes on top.

This modularity means the hive's capacity is only limited by the strength of the colony and the beekeeper's ability to stack the boxes.

Standardized, Interchangeable Components

Langstroth hives are built to specific, universal dimensions. This standardization is a massive advantage for any beekeeper with more than one hive.

Frames, boxes, lids, and bottoms are all interchangeable. This simplifies management, allows for the easy swapping of resources between hives, and creates a massive market for compatible equipment.

Designed for Centrifugal Extraction

The entire system is optimized for the most efficient extraction method: the centrifugal extractor.

The removable frames are designed to be uncapped and spun in a machine that pulls the honey out without destroying the wax comb, a critical factor for productivity.

How the Langstroth System Maximizes Honey Yield

Several features work together to channel the bees' efforts directly into honey storage and make the beekeeper's work more effective.

The Queen Excluder

A key tool is the queen excluder, a screen placed between the lower brood boxes and the upper honey supers.

This device prevents the larger queen from moving into the upper boxes to lay eggs. This ensures the honey supers contain only pure honey, making harvesting clean and straightforward.

Reusable Comb for Faster Production

Centrifugal extraction keeps the delicate beeswax comb intact. This is a massive energy-saver for the bees.

Returning the empty-but-intact comb to the hive allows the bees to immediately begin refilling it with honey, bypassing the resource-intensive process of building new wax. This dramatically speeds up the production cycle.

Focused Colony Management

The box-and-frame system allows the beekeeper to easily inspect the colony's health, manage pests, and ensure the queen is productive.

A strong, healthy colony is a productive one. The Langstroth design provides the visibility and access needed to maintain the colony at peak strength for honey gathering.

Understanding the Trade-offs

The Langstroth's focus on high-volume production comes with clear disadvantages that make it unsuitable for some beekeepers.

The Need for Specialized Equipment

To realize the hive's potential, you must invest in additional equipment. The most significant cost is a honey extractor, which can be expensive.

This contrasts sharply with methods like a Flow Hive, which has built-in extraction, or a top-bar hive, where honey is simply crushed and strained.

Higher Labor and Intrusiveness

Harvesting a Langstroth hive is labor-intensive. It involves lifting heavy boxes, transporting frames, and operating the extraction machinery.

The process is also highly disruptive to the colony, as the hive must be opened, and frames must be physically removed for processing.

Not Ideal for All Honey Types

This system is purpose-built for producing liquid, filtered honey.

If your goal is to produce other premium products like chunk honey (comb suspended in a jar of honey) or cut-comb honey, other hive types and extraction methods, such as a simple honey press, are often more suitable.

Making the Right Choice for Your Goal

Selecting a hive is about matching the equipment to your specific objective. Consider what kind of beekeeper you want to be before you invest.

- If your primary focus is maximizing honey sales and running a serious operation: The Langstroth hive is the industry standard for its unmatched scalability and efficiency at volume.

- If your primary focus is hobby beekeeping with easy, small-scale harvesting: A Flow Hive offers a less intrusive and labor-intensive method better suited for backyard enjoyment.

- If your primary focus is natural beekeeping and producing unique products like chunk honey: Other hive designs combined with a honey press will better align with your production goals.

Ultimately, choosing the right hive means aligning your equipment with your specific beekeeping philosophy and production goals.

Summary Table:

| Advantage | Key Benefit for Honey Production |

|---|---|

| Scalable Design | Unlimited vertical expansion with stackable boxes to match colony growth and nectar flow. |

| Standardized Components | Interchangeable frames and boxes simplify management and enable use of large-scale extraction equipment. |

| Optimized for Extraction | Frames are designed for centrifugal extractors, allowing efficient, non-destructive honey harvesting. |

| Queen Excluder | Ensures honey supers remain free of brood, resulting in pure, easily harvested honey. |

| Reusable Comb | Intact comb after extraction allows bees to refill immediately, speeding up production cycles. |

Ready to Scale Your Honey Production with the Right Equipment?

As a commercial beekeeper or distributor, maximizing efficiency is key to your success. The Langstroth hive is the proven foundation for high-volume operations.

HONESTBEE supplies the durable, standardized Langstroth hives, frames, and compatible extraction equipment you need to build a scalable and profitable honey production system. We support commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations.

Contact HONESTBEE today to discuss your bulk equipment needs and learn how we can help you achieve superior honey yields.

Visual Guide

Related Products

- Ergonomic Two Person Foldable Hive Lifter

- Stainless Steel 9 Frame Hive Spacer Durable Precise for Commercial Beekeeping

- Professional Grade Foldable Beehive Handles

- Professional Drop-Style Hive Handles for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What are the advantages of modern movable frame hives? Boost Yields with Advanced Beekeeping Hardware

- What is the practical significance of using a standard Langstroth Hive for bee disease management field validation?

- Why are insulation quilts and mud sealing techniques required for beehives? Protect Your Colony's Winter Survival

- What is the recommended distance between a beehive and its water source? Boost Your Hive's Efficiency

- What are the primary material advantages of modern movable frame hives? Maximize Honey Yield & Efficiency