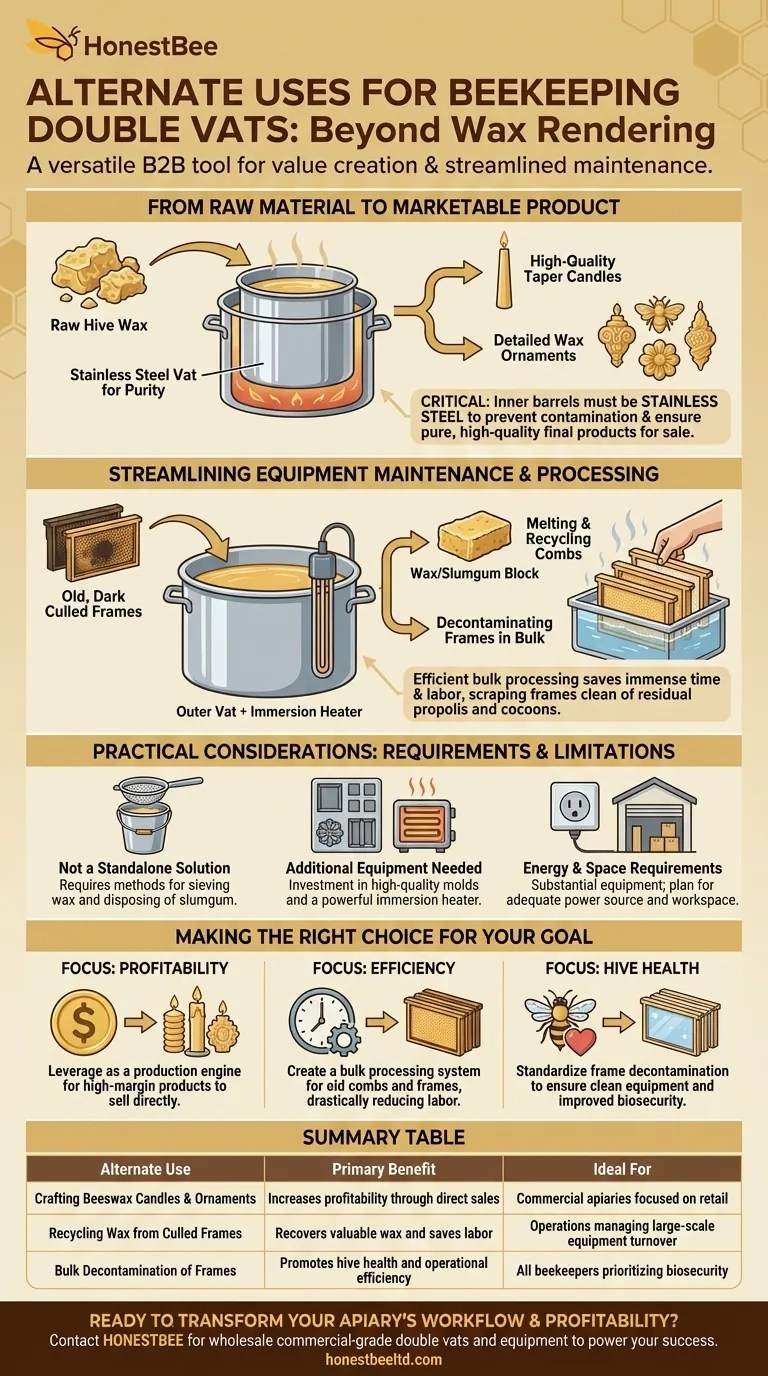

Beyond simple wax rendering, a beekeeping double vat is a surprisingly versatile tool that can be repurposed for both creating value-added products and streamlining critical equipment maintenance. Its alternate functions center on crafting high-quality beeswax candles and ornaments, and efficiently processing and decontaminating hive components like culled frames.

A double vat's true value is unlocked when you see it not just as a wax melter, but as a central processing hub for your entire apiary—transforming raw byproducts into profitable goods and turning labor-intensive cleanup into an efficient, bulk process.

From Raw Material to Marketable Product

A double vat excels at turning the raw wax from your hives into finished products that can significantly increase your operation's profitability. This workflow transforms a raw byproduct into a refined, marketable good.

Creating Value-Added Wax Goods

The most common alternate use is for crafting. The controlled heat of a double vat is ideal for making long taper candles and detailed wax ornaments.

This method allows for bulk production, which is especially useful if you plan to sell your products. Inexpensive rubber molds can be used to create a wide variety of ornaments for sale at markets or online.

The Critical Role of Stainless Steel

For any application involving products for sale or personal use (like candles), the inner barrels of your vat must be made of stainless steel.

This prevents discoloration or contamination of the wax, ensuring a pure, high-quality final product that maintains its natural color and scent.

Streamlining Equipment Maintenance and Processing

Perhaps the most powerful, and often overlooked, use for components of a double vat system is in managing old equipment. This saves an immense amount of time and labor.

Recycling Combs from Culled Frames

An outer vat paired with an immersion heater becomes an incredibly effective tool for recycling wax from old, dark frames that have been removed from service.

This process melts the wax from the wooden frames, allowing it to be separated and collected as a wax/slumgum block. This block can then be set aside for further, more refined processing later.

Decontaminating Frames in Bulk

While the wax is melting, the now-bare wooden frames are soaking in the hot water bath. This makes it exceptionally easy to scrape them clean of residual propolis and cocoons.

Furthermore, this hot soak is an excellent opportunity to decontaminate the frames, preparing them for reuse with new foundation. This bulk cleaning and sanitizing process is far more efficient than handling frames one by one.

Understanding the Practical Considerations

While a double vat is a powerful tool, its effective use depends on understanding its requirements and limitations. It is not a magic bullet, but a component of a larger system.

Not a Standalone Solution

The vat excels at melting and separating, but it is part of a workflow. You will still need methods for sieving the rendered wax to remove impurities and a clear plan for disposing of the leftover slumgum.

It's More Than Just the Vat

To use the vat for comb recycling, you need a powerful immersion heater for the outer barrel. For product creation, you will need to invest in high-quality molds for candles or ornaments.

Energy and Space Requirements

These are substantial pieces of equipment that require adequate workshop space and access to a suitable power source, especially when running a high-wattage immersion heater. Plan your workspace and electrical capacity accordingly.

Making the Right Choice for Your Goal

To get the most out of your equipment, align its use with the primary objective of your beekeeping operation.

- If your primary focus is profitability: Leverage the vat as a production engine for high-margin taper candles and wax ornaments to sell directly to consumers.

- If your primary focus is operational efficiency: Use an outer vat and heater to create a bulk processing system for old combs and frames, drastically reducing cleanup labor.

- If your primary focus is hive health: Make the frame decontamination process a standard part of your apiary management to ensure equipment is clean for future use.

By viewing it as a multi-purpose workstation, a double vat becomes a central asset for a modern and sustainable apiary.

Summary Table:

| Alternate Use | Primary Benefit | Ideal For |

|---|---|---|

| Crafting Beeswax Candles & Ornaments | Increases profitability through direct sales | Commercial apiaries focused on retail |

| Recycling Wax from Culled Frames | Recovers valuable wax and saves labor | Operations managing large-scale equipment turnover |

| Bulk Decontamination of Frames | Promotes hive health and operational efficiency | All beekeepers prioritizing biosecurity |

Ready to transform your apiary's workflow and profitability?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable tools needed for modern beekeeping. Our wholesale-focused operations ensure you get the reliable equipment—like commercial-grade double vats and immersion heaters—to efficiently create value-added products and maintain your hive components.

Contact HONESTBEE today to discuss your wholesale needs and discover how our supplies can power your apiary's success.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What role do specialized wax melters and filtration consumables play in the beeswax refining process? Key Quality Controls

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- How do steam wax melting machines support the biological control of Varroa mites? Stop Parasite Spread and Recover Wax

- What is the significance of wax melting tanks for the development of beekeeping byproducts? Boost Your Revenue

- What should be done if melted beeswax starts to solidify? Tips for Re-melting and Workflow Management