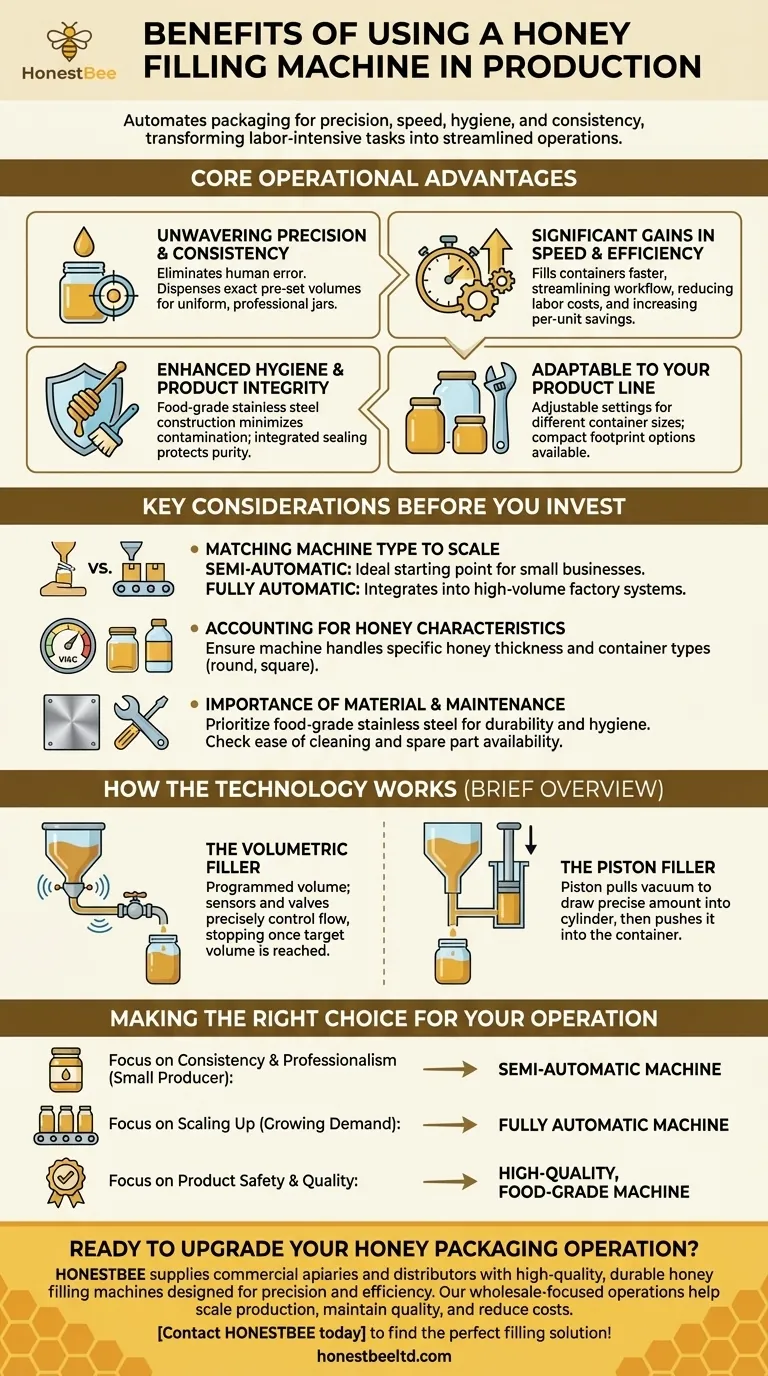

At its core, a honey filling machine automates the packaging process to deliver significant improvements in precision, speed, hygiene, and consistency. This technology transforms a labor-intensive task into a streamlined operation, reducing waste and labor costs while ensuring a professional and reliable product presentation for your customers.

The decision to use a honey filling machine is not just about filling jars faster. It is about implementing a system that elevates product quality, enhances operational efficiency, and provides the scalability needed for business growth.

The Core Operational Advantages

Investing in a honey filling machine introduces several fundamental improvements to your production line, moving beyond manual limitations to create a more professional and efficient process.

Unwavering Precision and Consistency

Manual filling is prone to human error, resulting in inconsistent fill levels. A filling machine solves this directly.

By dispensing an exact, pre-set volume of honey, it eliminates costly overfilling and frustrating underfilling. This consistency ensures every jar meets label specifications and presents a uniform, professional appearance on the shelf.

Significant Gains in Speed and Efficiency

A machine can fill containers at a rate far exceeding manual capabilities. This immediately streamlines your entire production workflow.

The reduction in manual labor translates directly to lower per-unit costs and frees up valuable time for other critical business activities.

Enhanced Hygiene and Product Integrity

Maintaining the purity of your honey is paramount. Reputable machines are constructed from food-grade, corrosion-resistant materials like stainless steel.

This minimizes the risk of contamination. Furthermore, integrated sealing and labeling processes protect the honey from spoilage and ensure a tamper-evident, shelf-ready product.

Adaptable to Your Product Line

Modern fillers are designed for versatility. They feature adjustable settings to accommodate a wide range of container sizes and shapes.

Many are also engineered with a compact footprint, making them a viable option even for small-scale producers like apiaries or food startups where space is a premium.

Understanding the Key Considerations Before You Invest

While the benefits are clear, choosing the right machine requires careful thought. An objective assessment of your specific needs is crucial for a successful investment.

Matching Machine Type to Your Scale

The primary decision is between semi-automatic and fully automatic systems.

A semi-automatic machine, which requires an operator to place and remove containers, is often the ideal starting point for small businesses. A fully automatic machine integrates into a larger conveyor system and is suited for high-volume factories.

Accounting for Honey Characteristics

Not all honey is the same. The viscosity of your product and the types of containers you use are critical factors.

Ensure the machine you choose can handle your specific honey's thickness and is compatible with your jars, whether they are glass or plastic, round or square.

The Importance of Material and Maintenance

Look for machines built with food-grade stainless steel. This not only ensures hygiene but also provides long-term durability.

Consider the ease of cleaning and disassembly, as this will be a regular part of your operational routine. Inquire about the availability of spare parts and reliable after-sales support.

How the Technology Works: A Brief Overview

Understanding the mechanics can help you choose the right machine. Most honey fillers fall into two main categories based on their filling mechanism.

The Volumetric Filler

This type of machine is programmed with a specific volume. Honey flows from a hopper to the nozzle, and a system of sensors and valves precisely controls the flow, cutting it off once the target volume is reached.

The Piston Filler

In a piston filler, the container is placed under the nozzle. The piston pulls back, creating a vacuum that draws a precise amount of honey from the hopper into a cylinder. The piston then pushes forward, dispensing that exact amount into the container.

Making the Right Choice for Your Operation

Your specific goal will determine the best path forward.

- If your primary focus is improving consistency and professionalism as a small producer: A semi-automatic machine offers a significant upgrade over manual filling without the cost of a fully automated line.

- If your primary focus is scaling up to meet growing demand: A fully automatic machine is a necessary investment to dramatically increase output and reduce long-term labor costs.

- If your primary focus is guaranteeing product safety and quality: Prioritize a machine constructed from high-quality, food-grade stainless steel that is easy to disassemble and clean.

Ultimately, integrating a honey filling machine is about taking control of your production to build a more efficient, scalable, and trusted brand.

Summary Table:

| Benefit | Description |

|---|---|

| Precision & Consistency | Eliminates over/under-filling for uniform, professional jars. |

| Speed & Efficiency | Fills containers faster, reducing labor costs and per-unit costs. |

| Hygiene & Integrity | Food-grade stainless steel construction minimizes contamination risk. |

| Adaptability | Adjustable settings for various container sizes and shapes. |

Ready to upgrade your honey packaging operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable honey filling machines designed for precision and efficiency. Our wholesale-focused operations ensure you get the reliable equipment you need to scale your production, maintain product quality, and reduce costs.

Contact HONESTBEE today to find the perfect filling solution for your business!

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- Why use industrial honey filling equipment for GI certification? Ensure Compliance and Premium Market Value

- How do high-standard honey filling and sealing machines contribute to honey quality? Secure Your Export Standards

- What are the advantages of utilizing automatic honey filling machinery in large-scale processing centers? Scale Your Output

- How does a jar or bottle packing machine function? Automate Your Packaging Line for Precision and Speed

- What essential equipment is required to manufacture honey sticks? A Complete Guide to Honey Straw Production Gear

- What are the advantages of using automated filling machines for apitherapy? Scaling Medical-Grade Production

- Why use professional industrial honey-filling machines? Boost Your Production Efficiency and Market Reach

- What types of products can be filled and packed using sachet filling and packing machines? Versatile Packaging for Liquids, Pastes & Spreads