At its core, motorizing a honey extractor transforms the process from a physically demanding task into a highly efficient, automated workflow. The primary benefits are a significant increase in productivity, a dramatic reduction in the time and effort required for extraction, and precise speed control that minimizes damage to the delicate honeycombs.

The decision to use a honey extractor motor is not just about convenience; it's a strategic choice that balances the scale of your operation against your desired level of hands-on involvement in the beekeeping process.

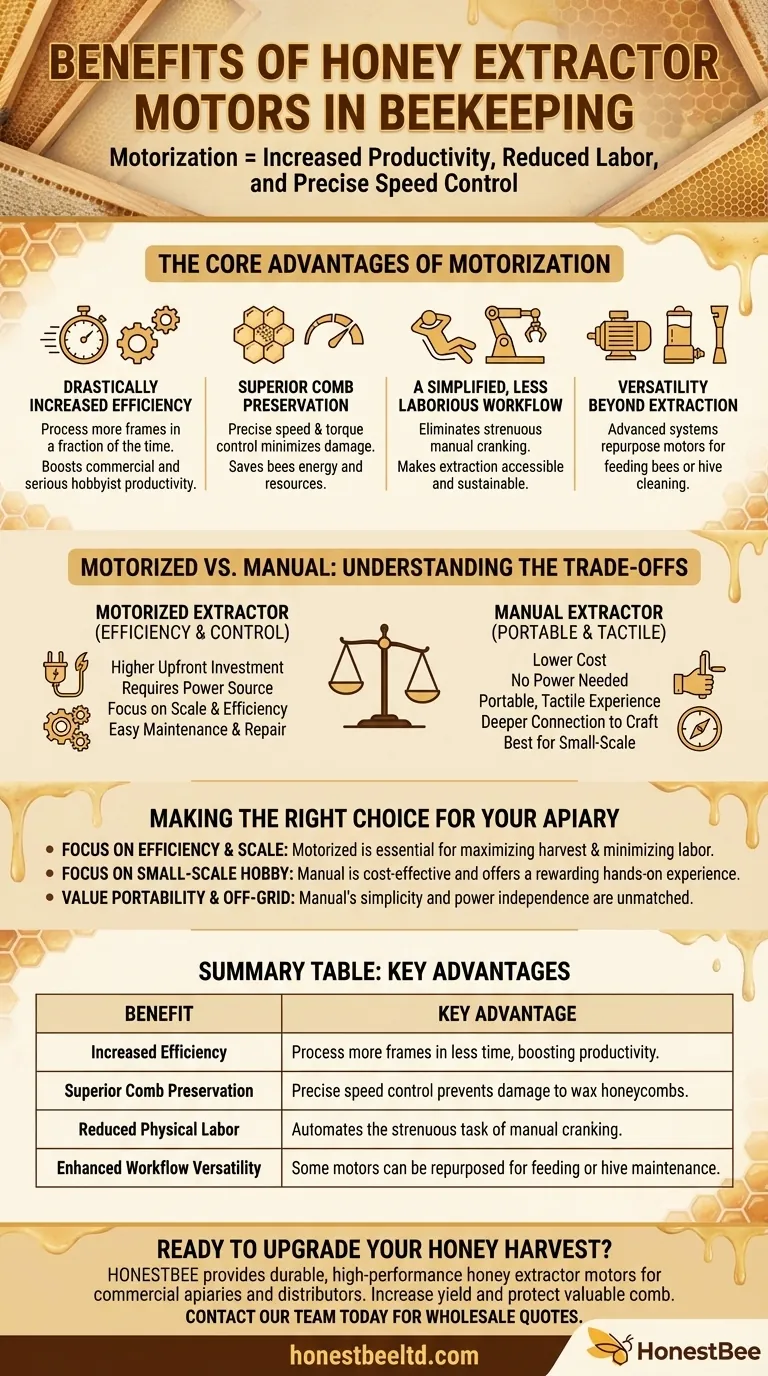

The Core Advantages of Motorization

Adding a motor to your honey extractor introduces a level of efficiency and control that is difficult to achieve manually, especially as the number of hives you manage grows.

Drastically Increased Efficiency

A motor allows you to process more frames in less time. This increased productivity is critical for both commercial operations and serious hobbyists looking to streamline their harvest.

What might take hours of manual cranking can often be completed in a fraction of the time, freeing you to focus on other essential apiary tasks.

Superior Comb Preservation

One of the most significant benefits is the precise control over speed and torque. Motors allow for a gradual ramp-up of speed, which gently extracts honey without blowing out the wax comb.

Preserving the comb is crucial. It saves the bees an immense amount of energy and resources, as they can immediately begin refilling the undamaged cells rather than having to rebuild them from scratch.

A Simplified, Less Laborious Workflow

Manual extraction is physically demanding. A motor eliminates the repetitive, strenuous effort of hand-cranking, making the entire process more accessible and sustainable, particularly for beekeepers with physical limitations.

Versatility Beyond Extraction

Some advanced systems allow the motor to be repurposed for other apiary tasks. These can include powering equipment for feeding bees or running tools for cleaning and maintaining hives, adding value to your initial investment.

Understanding the Trade-offs: Motorized vs. Manual

While motors offer clear advantages in efficiency, the manual extractor still holds a valuable place, particularly for certain types of beekeepers. Understanding the comparison is key to making an informed choice.

The Case for Manual Control

Manual extractors are often favored by hobbyists with only a few hives. They require no power source, making them portable and convenient for use in the field or in off-grid locations.

The hands-on approach provides a tactile experience, allowing the beekeeper to feel the changing weight of the frames and adjust speed intuitively. This fosters a deeper connection to the craft for those who enjoy being intimately involved in every step.

Cost and Complexity

Motorized systems represent a higher upfront investment compared to their manual counterparts. While generally designed for easy maintenance and repair, they introduce electrical components that can potentially fail over time.

In contrast, manual extractors are mechanically simpler and generally more affordable, presenting a lower barrier to entry for new beekeepers.

Making the Right Choice for Your Apiary

Your decision should be guided by the scale of your operation and your personal beekeeping philosophy.

- If your primary focus is efficiency and scale: A motor is an essential tool for maximizing your honey harvest and minimizing labor.

- If your primary focus is a small-scale hobby: A manual extractor is a cost-effective and perfectly suitable choice that offers a rewarding, hands-on experience.

- If you value portability and off-grid capability: The simplicity and power independence of a manual extractor cannot be beaten.

Ultimately, choosing the right extraction method is about aligning your equipment with the specific goals you have for your apiary.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Increased Efficiency | Process more frames in less time, boosting productivity. |

| Superior Comb Preservation | Precise speed control prevents damage to wax honeycombs. |

| Reduced Physical Labor | Automates the strenuous task of manual cranking. |

| Enhanced Workflow Versatility | Some motors can be repurposed for feeding or hive maintenance. |

Ready to upgrade your honey harvest? As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides durable, high-performance honey extractor motors designed for scale and reliability. Let us help you increase your yield and protect your valuable comb. Contact our team today to discuss your equipment needs and request a wholesale quote!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- Vertical Motor Kits for 2 3 4 Frame Electric Honey Extractors

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency

- What are the two common types of honey extractors? Choose the Right Extractor for Your Apiary

- What are the advantages of using an electric honey extractor? Boost Your Harvest Efficiency & Yield

- How long does it take to extract honey with an electric extractor? Automate Your Harvest for Greater Efficiency

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency