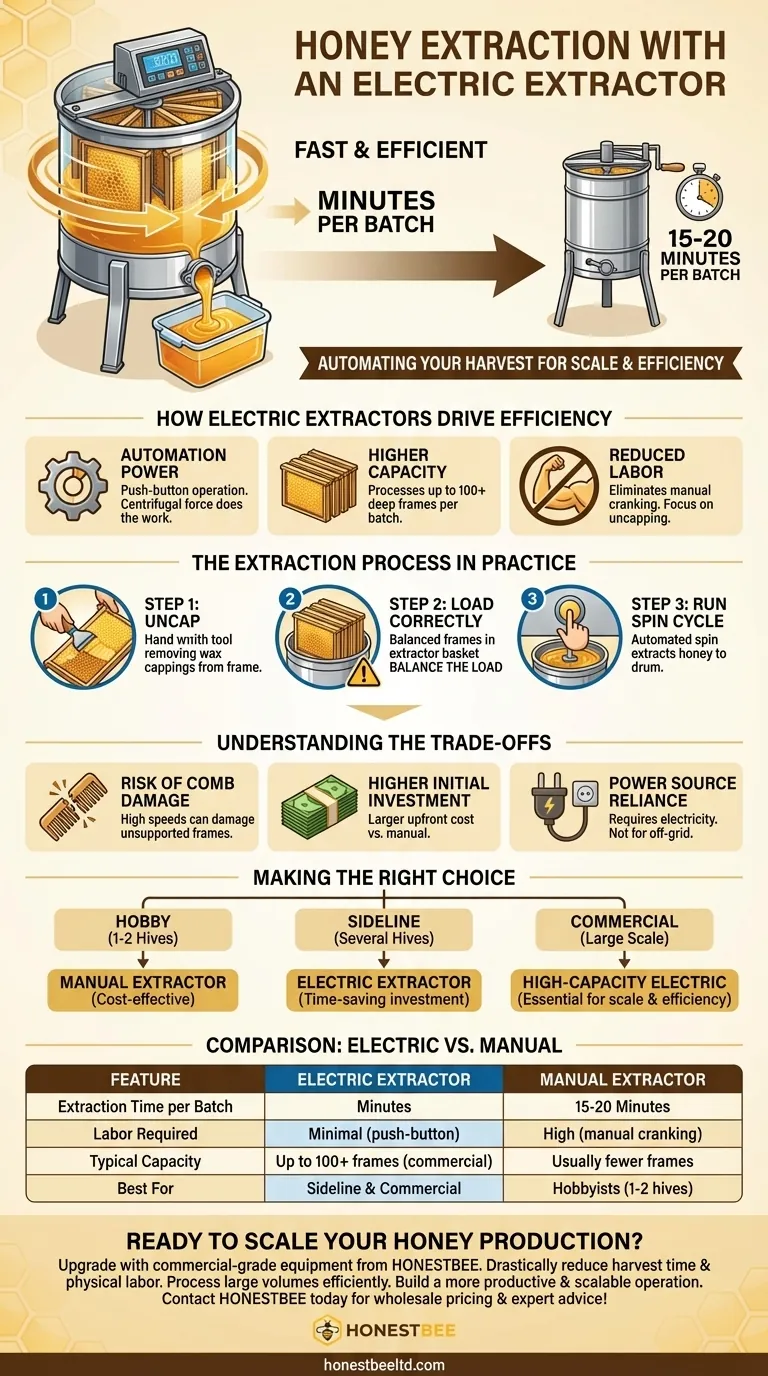

For an electric honey extractor, the process of spinning the honey out of a batch of frames typically takes just a matter of minutes. This is a significant improvement over manual extractors, which can take 15 to 20 minutes for a smaller batch. The true efficiency, however, comes from the automated process and the ability to handle a much larger number of frames at once.

The core value of an electric extractor isn't just about the speed of a single spin cycle. It's about fundamentally changing the scale and effort of your entire honey harvest by automating the most labor-intensive step.

How Electric Extractors Drive Efficiency

An electric extractor's advantage lies in its ability to automate the extraction process, drastically reducing physical labor and processing time. This makes it a critical tool for any beekeeper managing more than one or two hives.

The Power of Automation

With an electric extractor, the process begins with the push of a button. A motor spins the frames, using centrifugal force to pull the honey from the honeycomb cells without requiring any physical effort from the beekeeper.

Higher Capacity and Throughput

Electric models are built to handle larger volumes. While small versions can hold a few frames, commercial-scale extractors can process as many as 100 deep frames in a single batch, making them indispensable for serious honey production.

Reduced Physical Labor

The primary benefit beyond speed is the elimination of manual cranking. This allows you to focus on other tasks like uncapping the next batch of frames while the machine does the work.

The Extraction Process in Practice

While the spinning is automated, a successful harvest requires careful preparation and operation to protect your equipment and your honeycomb.

Step 1: Uncap the Frames

Before placing frames in the extractor, you must carefully remove the thin layer of wax cappings that bees build to seal the honey in the cells.

Step 2: Load the Extractor Correctly

Place the uncapped frames into the baskets inside the extractor. It is crucial to balance the load by placing frames of similar weight opposite each other to prevent violent shaking that could damage the extractor.

Step 3: Run the Spin Cycle

Once loaded, you simply turn the machine on. The automated spin cycle will extract the honey, which then drains to the bottom of the drum to be collected.

Understanding the Trade-offs

While highly efficient, electric extractors are not without their considerations. Objectivity requires acknowledging their potential downsides.

The Risk of Comb Damage

The high speeds of an electric extractor can generate immense force. Frames that lack proper wire or plastic foundation support can break apart during the spin, resulting in a significant loss of honeycomb.

Higher Initial Investment

Electric extractors represent a larger upfront cost compared to their manual counterparts. The convenience and efficiency come at a price that may not be justifiable for a beekeeper with only a single hive.

Reliance on a Power Source

Unlike a hand-crank model, an electric extractor requires a reliable source of electricity. This can be a limiting factor for beekeepers working in remote or off-grid apiaries.

Making the Right Choice for Your Goal

Selecting the right extractor depends entirely on the scale of your operation and your personal goals as a beekeeper.

- If your primary focus is managing one or two hobby hives: The time saved with an electric model may not outweigh the significant cost difference from a simple manual extractor.

- If your primary focus is growing a sideline business with several hives: An electric extractor is a powerful investment that saves significant time and physical effort, directly improving your productivity.

- If your primary focus is a commercial or large-scale operation: A high-capacity electric extractor is not a luxury; it is an essential piece of equipment for efficient and scalable honey processing.

Ultimately, choosing an electric extractor is about investing in efficiency to match the scale of your ambition.

Summary Table:

| Feature | Electric Extractor | Manual Extractor |

|---|---|---|

| Extraction Time per Batch | Minutes | 15-20 minutes |

| Labor Required | Minimal (push-button) | High (manual cranking) |

| Typical Capacity | Up to 100+ frames (commercial) | Usually fewer frames |

| Best For | Sideline businesses & commercial apiaries | Hobbyists with 1-2 hives |

Ready to Scale Your Honey Production?

Upgrade your harvest with a commercial-grade electric extractor from HONESTBEE. We supply durable, high-capacity beekeeping equipment designed for the demands of commercial apiaries and beekeeping equipment distributors.

Our electric extractors help you:

- Drastically reduce harvest time and physical labor.

- Process large volumes efficiently to meet growing demand.

- Build a more productive and scalable operation.

Contact HONESTBEE today for wholesale pricing and expert advice on the right equipment for your business goals!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How do automated honey extractors improve time efficiency? Boost Your Commercial Apiary Yield and Workflow

- What is the economic significance of industrial-grade honey extraction equipment? Scale Your Migratory Beekeeping Yields

- What is the working principle of industrial centrifugal honey extractors? Boost Yield with Advanced Extraction Tech

- What practical measures can be taken to manage the stickiness of honey during extraction? Expert Cleanliness Guide

- Why use professional centrifugal honey extractors in rural areas? Boost Turnover & Save Colony Energy

- What is the relationship between beeswax harvesting and honey extraction? An Inseparable Process Explained

- What are the advantages of using mobile honey extraction units in cedar forests? Boost Your Remote Apiary Efficiency

- What are the benefits of using an industrial-grade electric drive system for honey extractors? Boost Efficiency Today