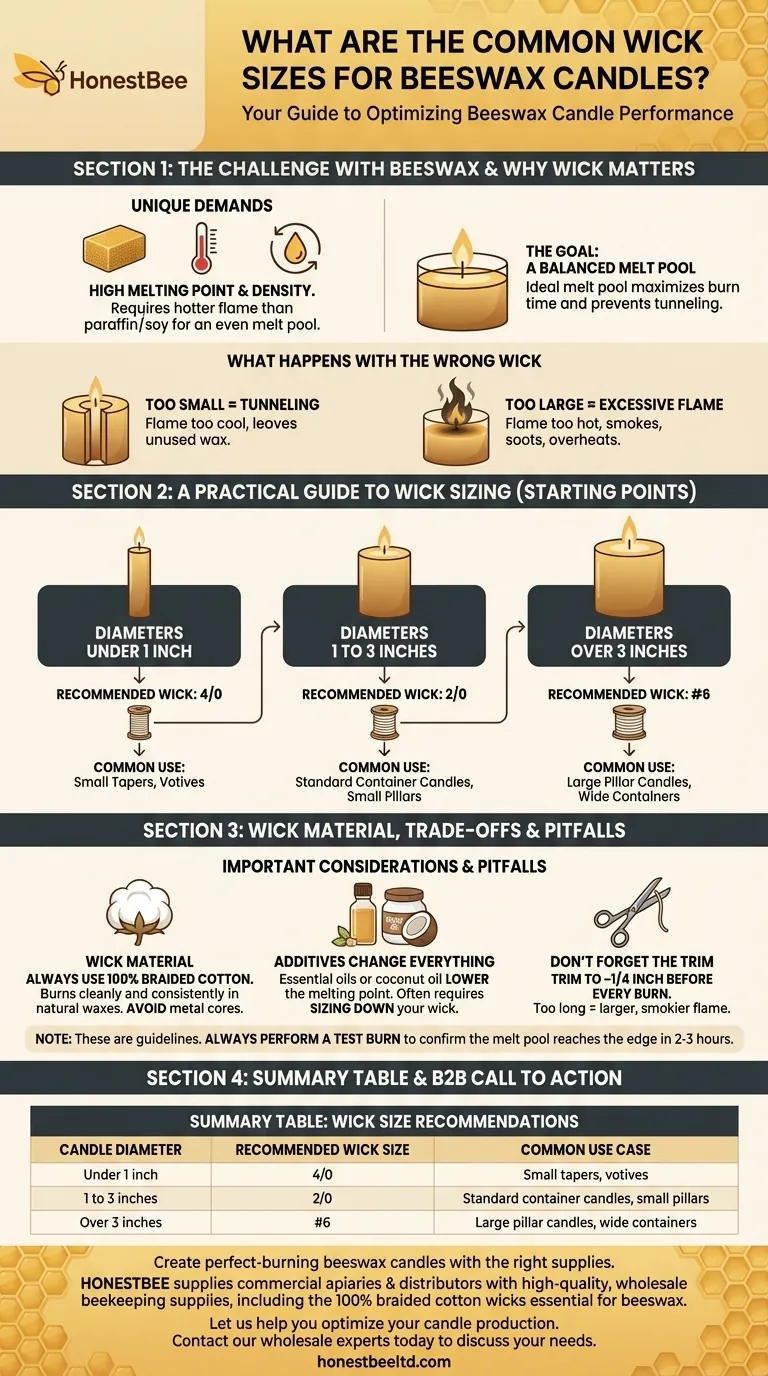

For beeswax candles, the correct wick size is determined by the candle's diameter. Common starting points are a 4/0 wick for candles under 1 inch, a 2/0 wick for diameters between 1 and 3 inches, and a #6 wick for candles larger than 3 inches in diameter.

The core challenge with beeswax is its high melting point and density. Unlike softer waxes, it requires a hotter flame to create an even melt pool, making the wick's size and material absolutely critical for a clean, efficient burn.

Why Wick Selection is Critical for Beeswax

Choosing a wick isn't just about making a candle light; it's about controlling the burn. This is especially true for beeswax, which behaves very differently from common paraffin or soy waxes.

The Unique Demands of Beeswax

Beeswax is a hard, dense wax with a high melting point. This means it requires significantly more heat to melt than other waxes.

The wick you choose must be able to draw up the melted beeswax and sustain a flame hot enough to create a consistent melt pool across the candle's surface.

The Goal: A Balanced Melt Pool

A "melt pool" is the puddle of liquid wax that forms around the wick as the candle burns.

The ideal melt pool extends fully to the edges of the candle. This ensures all the wax is consumed evenly, maximizing burn time and preventing a common issue called "tunneling."

What Happens with the Wrong Wick

An incorrect wick size will ruin a candle's performance.

- A wick that is too small will create a flame that isn't hot enough to melt the wax to the outer edge. The wick will burn straight down the center, leaving a thick wall of unused wax. This is known as tunneling.

- A wick that is too large will create an excessive flame. This consumes fuel too quickly, leading to smoke, soot, and a dangerously high flame that can overheat the container.

A Practical Guide to Wick Sizing

While testing is the only way to be certain, established guidelines provide an excellent starting point for your beeswax candle projects.

Standard Sizing Chart

Use these recommendations as a baseline for pure beeswax candles.

- For diameters under 1 inch: Use a 4/0 wick. This is ideal for small tapers and votives.

- For diameters of 1 to 3 inches: Use a 2/0 wick. This is the most common range for container candles and small pillars.

- For diameters over 3 inches: Use a #6 wick. This is necessary for large pillar candles or wide-mouth container candles.

The Importance of Wick Material

Always select wicks made of 100% braided cotton. These wicks are designed to burn cleanly and consistently in natural waxes.

Avoid wicks with zinc or other metal cores, as they are unnecessary for beeswax and can produce soot.

Understanding the Trade-offs and Pitfalls

Sizing charts are a guide, not a guarantee. Several factors can alter a candle's burn performance, requiring you to adjust your wick selection.

Always Perform a Test Burn

The single most important step is a test burn. Make one candle with your chosen wick and burn it for a few hours. This is the only way to truly know if you have a balanced melt pool.

Additives Change Everything

Adding essential oils for fragrance or coconut oil to soften the wax will change its melting point. These additives typically require you to size down your wick from what you would use for pure beeswax.

Don't Forget the Trim

Before every burn, the wick must be trimmed to approximately 1/4 inch. A wick that is too long will always produce a larger, smokier flame, regardless of whether it is the correct size.

Making the Right Choice for Your Project

Use your primary goal to determine your starting point, but always be prepared to test and adjust.

- If your primary focus is on small tapers or votives (under 1"): Start with a 4/0 wick, as a smaller flame is all that's needed for the narrow diameter.

- If your primary focus is on standard container candles (1-3"): A 2/0 wick is your most reliable starting point, but test to confirm the melt pool reaches the edge in about 2-3 hours.

- If your primary focus is on large pillars or multi-wick candles (over 3"): Begin with a #6 wick for a single-wick setup, understanding that large candles are the most challenging to get right and require rigorous testing.

Mastering the art of wicking is the key to creating beautiful, long-lasting beeswax candles.

Summary Table:

| Candle Diameter | Recommended Wick Size | Common Use Case |

|---|---|---|

| Under 1 inch | 4/0 | Small tapers, votives |

| 1 to 3 inches | 2/0 | Standard container candles, small pillars |

| Over 3 inches | #6 | Large pillar candles, wide containers |

Create perfect-burning beeswax candles with the right supplies.

Choosing the correct wick is critical for professional results. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, wholesale beekeeping supplies and equipment, including the 100% braided cotton wicks essential for beeswax.

Let us help you optimize your candle production. Contact our wholesale experts today to discuss your specific needs and ensure you have the right materials for success.

Visual Guide

Related Products

- Metal Wick Holder Centering Devices for DIY Candle Making Candle Wick Holder

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Honey Press Wax Press with Tank

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What is the significance of using beeswax casting molds? Transform Your Refined Wax into a Professional Commodity

- What is the step-by-step process for making a beeswax candle? Master the Art of Professional Candle Manufacturing

- What are some other beeswax candle projects you can try? Explore Tapers, Containers & Blends

- What are the characteristics and production methods for beeswax candles? Master the Art of Premium Candle Making

- How many candles can you make with one pound of beeswax? A Guide to Calculating Your Yield

- What are the essential tools and materials for beeswax candle manufacturing? Start Your Commercial Production Today

- What is the third tip for working with beeswax in a silicone mold? Master the Critical Demolding Stage

- What equipment and tools are needed for making beeswax candles? Master the Melt for Safe, Quality Results