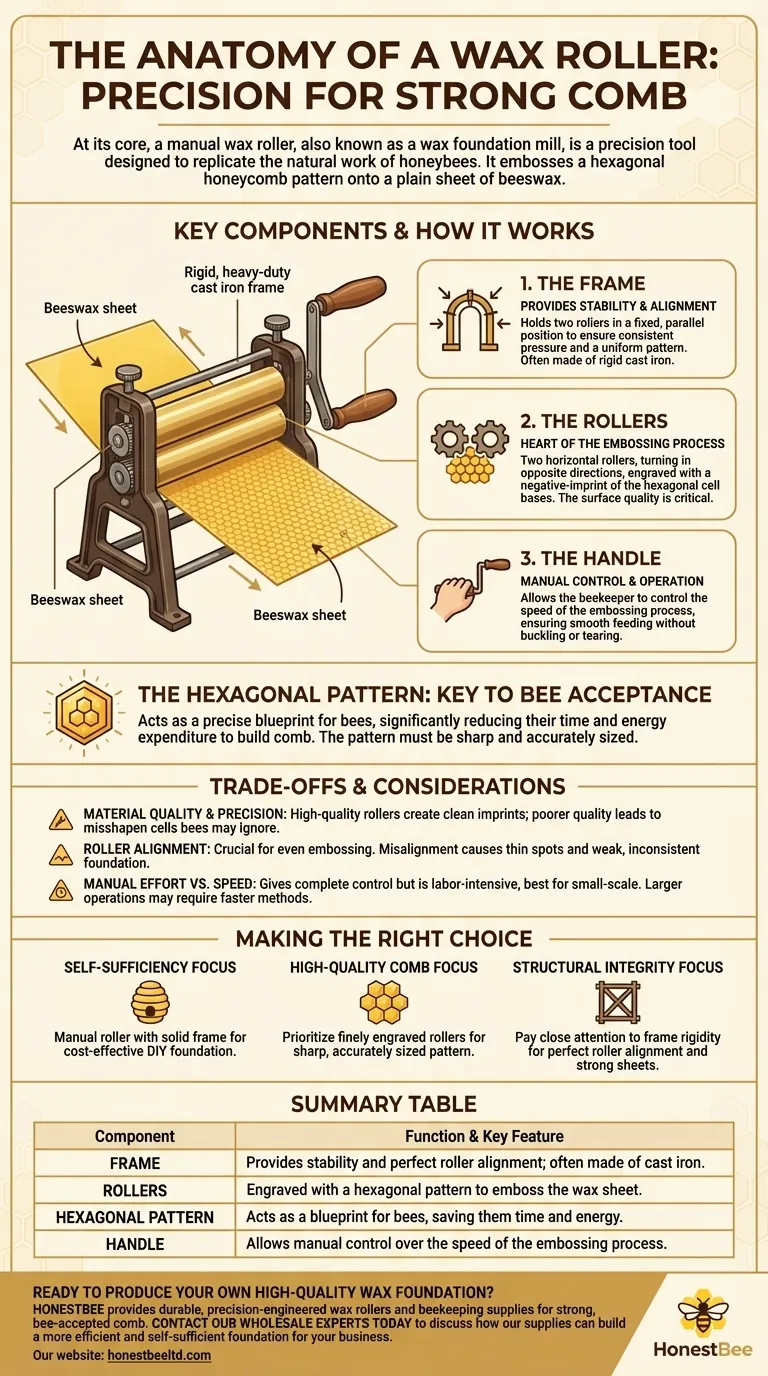

At its core, a manual wax roller, also known as a wax foundation mill, is a simple mechanical device comprised of three key components. It uses two precisely engraved rollers, a sturdy support frame, and a hand-cranked handle to emboss a hexagonal honeycomb pattern onto a plain sheet of beeswax.

A wax roller is more than just a press; it's a precision tool designed to replicate the natural work of honeybees. The function of each component is to ensure the resulting wax foundation provides a perfect, energy-saving guide for your bees to build their comb.

The Anatomy of a Wax Roller: How It Works

Understanding how each part contributes to the final product is key to appreciating the tool's function and importance in beekeeping. The design is simple, but the precision required is high.

The Frame: Providing Stability and Alignment

The entire assembly is held together by a rigid frame, which is often made of heavy-duty cast iron.

This frame serves a critical purpose: it holds the two rollers in a fixed, parallel position. This unwavering stability ensures consistent pressure is applied across the entire wax sheet, preventing tears and guaranteeing a uniform cell pattern.

The Rollers: The Heart of the Embossing Process

The machine features two horizontal rollers that turn in opposite directions. A plain sheet of beeswax is fed between them.

The surface of these rollers is the most critical feature. It is engraved with a negative-imprint of the hexagonal cell bases that form a honeycomb.

The Hexagonal Pattern: The Key to Bee Acceptance

The engraved honeycomb pattern is the reason this tool exists. It embosses the foundation of the cell walls onto the wax sheet.

This pattern acts as a blueprint for the bees. By providing them with a pre-formed base, it significantly reduces the time and energy (in the form of honey consumption) they must expend to draw out a full comb. The cell size must be precise to be readily accepted by the colony.

The Handle: Manual Control and Operation

A simple handle or hand crank is attached to one of the rollers.

Turning this handle manually provides the force needed to pull the wax sheet through the machine. This allows the beekeeper to control the speed and ensure the sheet feeds through smoothly without buckling or tearing.

Understanding the Trade-offs and Considerations

While the concept is straightforward, the quality of the components directly impacts the quality of the foundation you produce.

Material Quality and Precision

The material of the rollers and the precision of the engraving are paramount. High-quality rollers create a clean, sharp imprint that bees readily accept. Cheaper, poorly machined rollers can create misshapen cells that bees may ignore or modify, defeating the purpose.

The Importance of Roller Alignment

If the frame is not sufficiently rigid or the rollers are misaligned, the emboss will be uneven. One side of the wax sheet may be pressed too thin while the other is barely marked. This leads to weak, inconsistent foundation that can fail in the hive.

Manual Effort vs. Speed

A manual roller gives you complete control but is a labor-intensive process, best suited for small-scale apiaries. For larger operations, the time required to produce foundation for many hives can become a significant factor.

Making the Right Choice for Your Apiary

Understanding these components helps you evaluate a wax roller based on your specific goals as a beekeeper.

- If your primary focus is self-sufficiency in a small hobby apiary: A manual wax roller with a solid cast iron frame is a cost-effective tool for turning your own beeswax into usable foundation.

- If your primary focus is producing high-quality comb: Prioritize a machine with finely engraved rollers to ensure the hexagonal pattern is sharp and accurately sized for your bees.

- If your primary focus is structural integrity: Pay close attention to the frame's rigidity, as perfect roller alignment is non-negotiable for creating strong, uniform foundation sheets.

By understanding how these simple parts work together, you can better control the foundation of your entire beekeeping operation.

Summary Table:

| Component | Function & Key Feature |

|---|---|

| Frame | Provides stability and perfect roller alignment; often made of cast iron. |

| Rollers | Engraved with a hexagonal pattern to emboss the wax sheet. |

| Hexagonal Pattern | Acts as a blueprint for bees, saving them time and energy. |

| Handle | Allows manual control over the speed of the embossing process. |

Ready to produce your own high-quality wax foundation?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides durable, precision-engineered wax rollers and beekeeping supplies. Our equipment ensures the perfect roller alignment and sharp hexagonal patterns your operation needs for strong, bee-accepted comb.

Contact our wholesale experts today to discuss how our supplies can build a more efficient and self-sufficient foundation for your business.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Honey Uncapping Roller for Efficient Harvesting

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers

- What is the function of a beeswax foundation machine? Boost Hive Efficiency and Honey Production

- What are the cost-saving benefits of using fully automatic wax foundation machines? Maximize ROI for Commercial Apiaries

- Why is the introduction of a beeswax foundation machine considered an important step in improving honey yields?