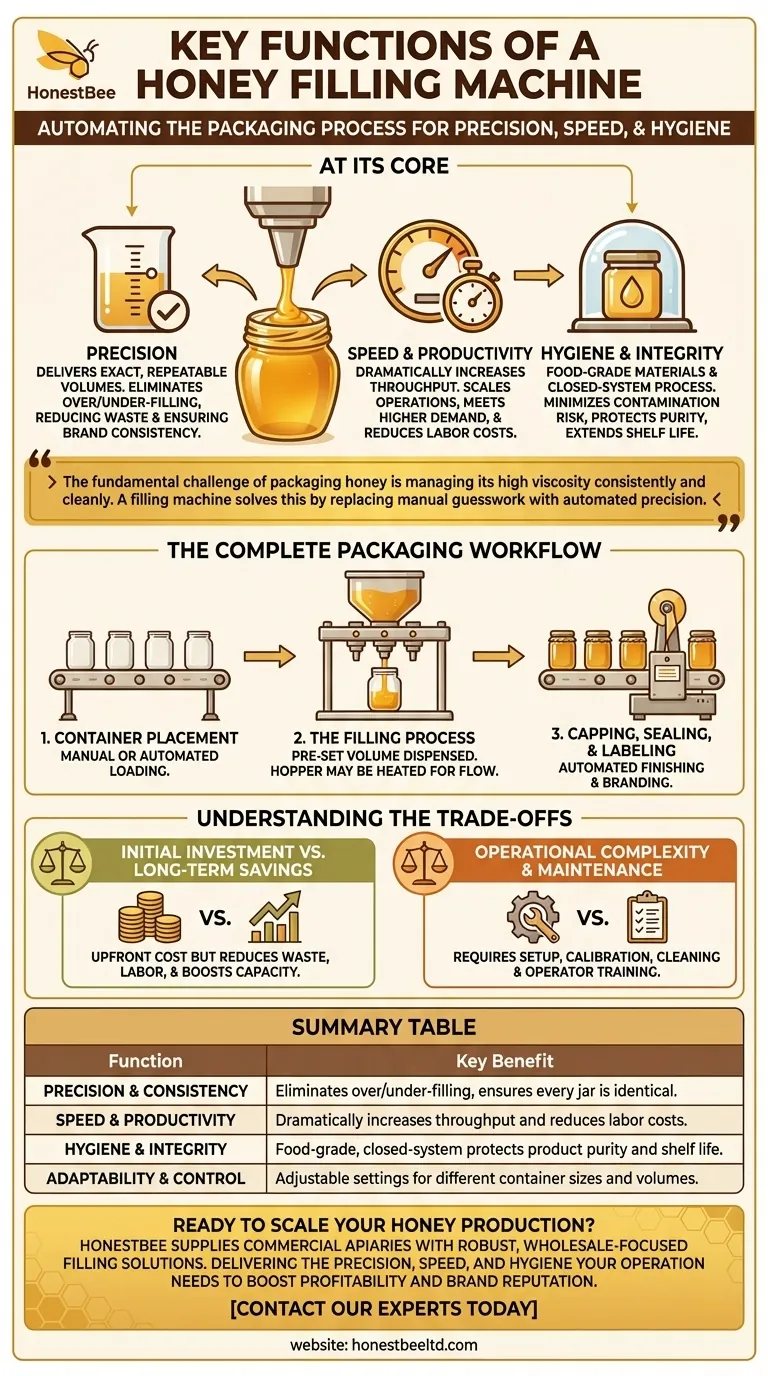

At its core, a honey filling machine automates the packaging process by delivering three primary functions: precision, speed, and hygiene. It is engineered to dispense an exact, repeatable volume of honey into containers far faster than manual methods while ensuring the product remains uncontaminated and professionally presented.

The fundamental challenge of packaging honey is managing its high viscosity consistently and cleanly. A filling machine solves this by replacing manual guesswork and labor with automated precision, ensuring every container is filled correctly, production targets are met, and the final product looks professional.

Breaking Down the Core Functions

A honey filling machine is more than just a dispenser. It is a specialized system designed to handle a uniquely challenging product while streamlining a critical business operation.

Precision and Consistency

The most critical function is delivering a precise volume of honey into every jar. This eliminates overfilling, which wastes product and profit, and underfilling, which can damage brand reputation and violate regulations.

This automated consistency ensures that the customer receives the same amount of product every time, building trust and reinforcing the quality of your brand.

Speed and Productivity

Compared to manual filling, a machine dramatically increases throughput. This allows you to scale your operation, meet higher demand, and reduce the bottlenecks commonly found in the packaging stage.

By automating this repetitive task, you also significantly reduce labor costs and free up personnel for more valuable activities.

Hygiene and Product Integrity

These machines are constructed from food-grade materials, typically stainless steel, to prevent contamination and make cleaning easier.

An automated, closed-system filling process minimizes the honey's exposure to air and potential human contact, protecting its purity and extending its shelf life.

Adaptability and Control

Most honey fillers feature adjustable volume settings. This allows you to use the same machine for various container sizes, from small sample jars to large retail containers, providing crucial operational flexibility.

The Complete Packaging Workflow

A filling machine is the heart of a packaging line. Understanding how it fits into the overall process reveals its true value.

Step 1: Container Placement

The process begins with placing empty jars or bottles onto a conveyor. This can be done manually by an operator or automatically by auxiliary equipment in a fully integrated line.

Step 2: The Filling Process

Containers are moved into position under the filling nozzle. The machine then dispenses the pre-set volume of honey. The honey is typically fed into the filler from a larger tank or hopper, which may be heated to reduce viscosity and improve flow.

Step 3: Capping, Sealing, and Labeling

After being filled, the containers move to subsequent stations. Here, they are automatically or semi-automatically capped and sealed. Further down the line, a labeling machine may apply the final branding before the product is boxed for shipping.

Understanding the Trade-offs

While highly beneficial, investing in a honey filling machine requires careful consideration of the associated compromises.

Initial Investment vs. Long-Term Savings

The primary barrier is the upfront capital cost. However, this must be weighed against the long-term savings from reduced product waste, lower labor expenses, and increased production capacity.

Operational Complexity

Unlike a simple funnel and scoop, these machines require setup, calibration, and regular cleaning. Operators need to be trained on proper use and maintenance to ensure consistent performance and hygiene.

Managing Honey's Viscosity

Honey's thickness changes significantly with temperature. Many filling systems incorporate heaters in the hopper to keep the honey fluid and ensure it flows smoothly and accurately, which can add to energy costs and operational oversight.

Making the Right Choice for Your Operation

Selecting the right machine depends entirely on your primary business goal.

- If your primary focus is scaling production: Prioritize a machine with a high filling speed (jars per minute) and options for full automation, including container feeding and capping.

- If your primary focus is product quality and branding: Choose a filler known for its high accuracy and drip-free performance to ensure a clean, professional finish on every jar.

- If your primary focus is operational efficiency: Calculate the return on investment based on reduced labor hours and minimized product waste to justify the initial expense.

By automating your filling process, you take direct control over your product's quality, consistency, and profitability.

Summary Table:

| Function | Key Benefit |

|---|---|

| Precision & Consistency | Eliminates over/under-filling, ensures every jar is identical. |

| Speed & Productivity | Dramatically increases throughput and reduces labor costs. |

| Hygiene & Integrity | Food-grade, closed-system protects product purity and shelf life. |

| Adaptability & Control | Adjustable settings for different container sizes and volumes. |

Ready to scale your honey production with professional-grade equipment?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused honey filling solutions. Our machines are designed to deliver the precision, speed, and hygiene your operation needs to boost profitability and brand reputation.

Contact our experts today to find the perfect filling machine for your business goals!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What technical challenges do automatic honey filling and capping machines address for large-scale packaging lines?

- How do automated honey-filling machines assist in evaluating honeybee health research? Quantify Your ROI Today

- How does professional labeling and filling equipment add value to stingless bee products? Maximize Your Market Premium

- What is the economic significance of standardized honey filling equipment? Scaling Commercial Success for Apiaries

- What are equipment used for filling? Match Your Product to the Perfect Filling Machine

- How do honey filling machines ensure product quality? Precision Technology for Large-Scale Beekeeping Success

- How do professional honey filling and labeling machines enhance competitiveness? Boost Brand Trust and Scale Profits

- What is a gravity honey filling machine and how does it function? Enhance Your Apiary's Packaging Efficiency