Choosing the right beehive is one of the most fundamental decisions a beekeeper makes. The Kenya Top-Bar Hive (KTBH) is a horizontal hive that promotes natural comb building and requires minimal equipment, making it simple and cost-effective. In contrast, the Langstroth hive is a vertical, modular system designed with interchangeable parts to maximize honey production, though it requires a higher initial investment in equipment like a centrifugal extractor.

Your choice between a KTBH and a Langstroth is not just about equipment; it's a decision between two distinct beekeeping philosophies. The KTBH prioritizes simplicity and alignment with natural bee behavior, while the Langstroth prioritizes operational efficiency and high-volume honey yield.

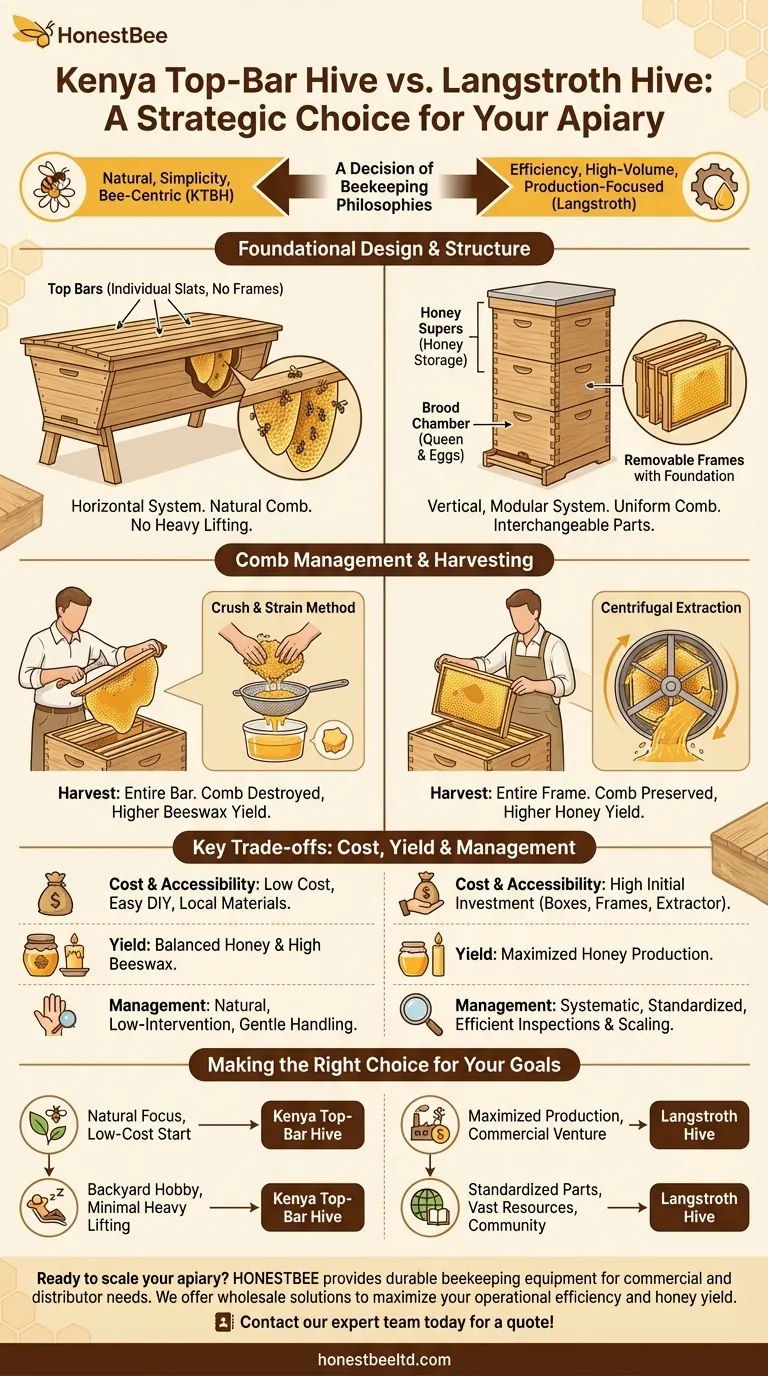

Foundational Design: Horizontal vs. Vertical

The most visible difference between the two hives is their orientation and structure, which dictates how the beekeeper manages the colony.

The KTBH: A Single-Story, Horizontal System

The KTBH is a long, single-story trough, typically with sloped sides, covered by a series of individual wooden slats called top bars.

Bees build their comb downwards from these bars, creating a natural, catenary curve shape within the hive body. Because it's a horizontal system, all inspection and management happen by moving bars from side to side, without any heavy lifting of stacked boxes.

The Langstroth: A Modular, Vertical System

The Langstroth hive is the commercial standard, composed of stacked, rectangular boxes. The bottom boxes are for the brood chamber, where the queen lays eggs, and upper boxes, called "supers," are added for honey storage.

Each box contains a set of removable frames, which typically hold a sheet of foundation (beeswax or plastic) to guide the bees in building straight, uniform comb. This standardization is the key to its efficiency.

Comb Management and Honey Harvesting

The method of honey extraction is a direct result of the hive's core design and represents a significant difference in labor, cost, and end products.

KTBH: Natural Comb and the "Crush and Strain" Method

In a KTBH, the beekeeper harvests entire bars of honey-filled comb. Because this comb is not supported by a full frame, it is fragile.

The honey is extracted using the crush and strain method: the comb is cut from the top bar, crushed, and the honey is drained through a sieve or filter. This process requires no special machinery but results in the destruction of the comb. A valuable byproduct of this method is a higher yield of beeswax.

Langstroth: Frames and Centrifugal Extraction

In a Langstroth, the beekeeper removes entire frames of honey. Because the comb is fully supported and reinforced by the frame, it can be placed in a centrifugal extractor.

This machine spins the frames at high speed, forcing the honey out of the cells while leaving the beeswax comb intact. These empty "drawn" combs can then be returned to the hive, saving the bees immense energy and dramatically speeding up the next honey production cycle.

Understanding the Trade-offs

Neither hive is universally "better"; they are simply optimized for different goals. Understanding their trade-offs is crucial for making an informed decision.

Cost and Accessibility

The KTBH is significantly less expensive and easier to build. Its simple design can be constructed from locally sourced materials with basic woodworking skills, making it highly accessible for hobbyists or beekeepers in developing areas.

The Langstroth system requires a higher capital investment. The milled, standardized boxes, frames, and especially the centrifugal extractor represent a significant upfront cost.

Honey Yield vs. Wax Yield

The Langstroth is engineered to maximize honey production. By preserving the drawn comb, it allows the colony to focus its energy purely on gathering nectar and making honey, leading to much larger harvests.

The KTBH, by requiring the bees to constantly rebuild comb after harvest, yields less honey. However, it produces a significantly larger and more readily available supply of high-quality beeswax.

Management and Philosophy

Managing a KTBH is often seen as a more "natural" or low-intervention form of beekeeping. Inspections are less disruptive and involve no heavy lifting. However, handling the fragile, free-form combs requires a gentle and careful touch.

The Langstroth is built for systematic management. Its interchangeable parts make it easy to inspect hives, treat for pests, and scale an operation. This efficiency is why it dominates commercial beekeeping.

Making the Right Choice for Your Goals

Your personal goals as a beekeeper are the most important factor in choosing a hive.

- If your primary focus is natural beekeeping and a low-cost start: The KTBH is an excellent choice that prioritizes bee-centric practices and yields both honey and wax.

- If your primary focus is maximizing honey production or a commercial venture: The Langstroth's efficiency, scalability, and high-yield potential make it the clear industry standard.

- If your primary focus is a backyard hobby with minimal heavy lifting: The horizontal KTBH eliminates the need to lift heavy honey-filled boxes.

- If your primary focus is learning from a vast community and finding parts easily: The Langstroth is the most popular hive in the world, with a wealth of resources and standardized equipment.

Ultimately, the best hive is the one that aligns with your resources, physical ability, and beekeeping philosophy.

Summary Table:

| Feature | Kenya Top-Bar Hive (KTBH) | Langstroth Hive |

|---|---|---|

| Structure | Horizontal, single-story | Vertical, modular boxes |

| Comb Management | Natural, free-form comb | Frames with foundation for uniform comb |

| Honey Harvesting | Crush and strain method | Centrifugal extractor (comb preserved) |

| Primary Yield | Balanced honey and high beeswax | Maximized honey production |

| Initial Cost | Low (easy DIY build) | High (requires specialized equipment) |

| Best For | Natural beekeeping, hobbyists, low budget | Commercial operations, high-yield focus |

Ready to choose the right hive for your apiary? Whether you're a commercial beekeeper scaling up with Langstroth systems or a distributor seeking reliable KTBH components, HONESTBEE supplies the durable beekeeping equipment you need. We provide wholesale-focused solutions for commercial apiaries and distributors to maximize your operational efficiency and honey yield. Contact our expert team today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional Hive Top Bee Feeder for Beekeeping

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Telescopic Beehive Outer Cover Lid Roof with Galvanised Sheeting for Langstroth Hive and Beehive Outer Cover

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- How does bee behavior differ in 10-frame vs 8-frame hives? Optimize Your Apiary's Space Utilization

- What is the function of standard Langstroth beehives in field trials? Ensure Scientific Rigor in Chemical Assessments

- Why are Langstroth hives the standard in commercial beekeeping? Optimize Production and Varroa Research Efficiency

- What is the function of standardized Langstroth hives in honey bee colony assessment? Key Tools for Bee Population Accuracy

- What is the primary function of specialized Trigona and Apis cerana beehives? Maximize Colony Health and Honey Yield

- What are the technical advantages of using standardized Langstroth hives? Data-Driven Beekeeping Insights

- How do beekeepers manage the growth of a Langstroth hive? A Guide to Strategic Space Management

- What challenges exist when sourcing equipment for 8-frame beehives? Overcome Supply Chain and Stability Issues