At its core, a honey extractor is a simple machine. It spins honeycomb frames using centrifugal force to pull the honey out, but the way it accomplishes this task defines its type. The two fundamental designs are radial and tangential, which describe how the frames are positioned inside the drum, and these can be powered either manually or with a motor.

The choice between a honey extractor isn't just a matter of technical specifications; it's a strategic decision that should align with the scale of your beekeeping operation, your budget, and the amount of time you are willing to invest.

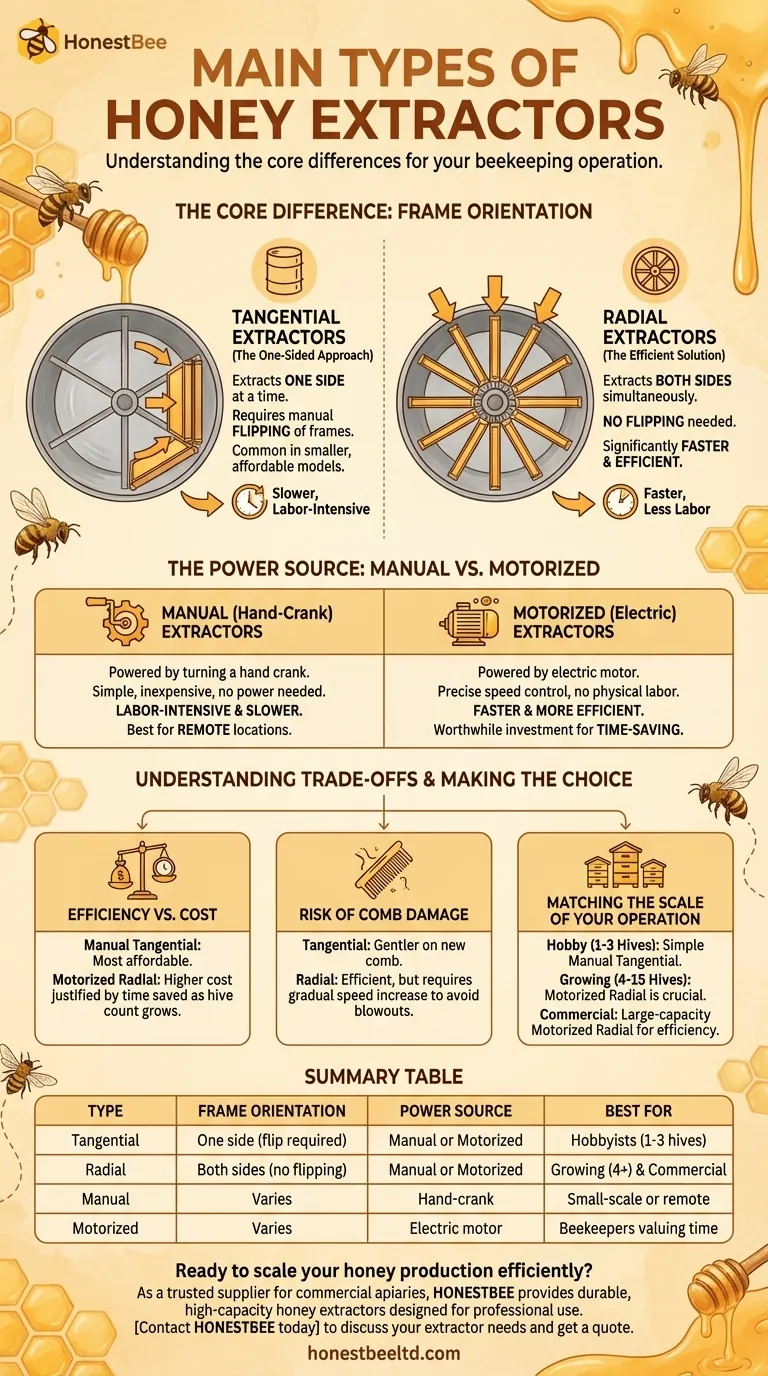

The Core Difference: Frame Orientation

The most important distinction between extractor types is how they hold the frames. This directly impacts efficiency, speed, and the amount of labor required during the extraction process.

Tangential Extractors: The One-Sided Approach

In a tangential extractor, the frame is positioned so that only one side of the honeycomb faces the outer wall of the drum.

This means that honey is extracted from one side of the frame at a time.

Once the first side is empty, you must stop the machine, manually flip each frame, and then spin again to extract the other side. This design is common in smaller, more affordable models.

Radial Extractors: The Efficient Solution

A radial extractor positions the frames vertically, like the spokes of a wheel, with the top bar of the frame facing the outer wall.

This clever orientation allows centrifugal force to pull honey from both sides of the comb simultaneously.

Because you don't have to flip the frames, the extraction process is significantly faster and requires less manual intervention, making this the standard for most beekeepers with more than a few hives.

The Power Source: Manual vs. Motorized

Beyond frame orientation, the second key difference is the power source. This choice dictates the physical effort and speed of the extraction.

Manual (Hand-Crank) Extractors

These extractors are powered by turning a hand crank, which spins the internal basket through a set of gears.

They are simple, relatively inexpensive, and do not require a power source, making them ideal for use in remote locations.

However, the process is labor-intensive and slower, best suited for beekeepers with only a handful of hives.

Motorized (Electric) Extractors

Motorized extractors use an electric motor to spin the basket, offering precise speed control and eliminating all physical labor.

This makes the extraction process significantly faster and more efficient, allowing you to process many more frames in a shorter amount of time.

While more expensive, a motorized unit is a worthwhile investment for any beekeeper who values their time and plans to manage more than three or four hives.

Understanding the Trade-offs

Choosing an extractor involves balancing cost, efficiency, and the specific needs of your apiary. There is no single "best" type, only the best type for your situation.

Efficiency vs. Cost

A small, manual tangential extractor is the most affordable entry point. However, the time saved by a motorized radial extractor quickly justifies its higher cost as your number of hives grows.

What might take a full day with a manual extractor can often be completed in a few hours with a motorized radial model.

Risk of Comb Damage

Tangential extractors can sometimes be gentler on delicate new comb because the force is applied evenly across one entire side.

Radial extractors are highly efficient but require you to gradually increase the speed. Spinning too fast too soon can cause the weight of the honey to "blow out" and destroy the comb foundation.

Matching the Scale of Your Operation

The number of hives you manage is the single most important factor. A two-frame manual extractor is perfectly sufficient for a backyard hobbyist.

Conversely, attempting to harvest from 20 hives with that same extractor would be a frustrating and exhausting multi-day task.

Making the Right Choice for Your Apiary

To make a clear decision, evaluate your goals and the current size of your operation.

- If your primary focus is a small hobby (1-3 hives): A simple manual tangential extractor is the most cost-effective and practical choice.

- If your primary focus is growing your apiary (4-15 hives): A motorized radial extractor is a crucial investment that will save you significant time and labor.

- If your primary focus is commercial or sideline production: A large-capacity, stainless steel motorized radial extractor is the only practical standard for efficiency.

Ultimately, choosing the right extractor is about matching the equipment's capabilities to the scale of your beekeeping journey.

Summary Table:

| Type | Frame Orientation | Power Source | Best For |

|---|---|---|---|

| Tangential | One side at a time (frames must be flipped) | Manual or Motorized | Hobbyists (1-3 hives) |

| Radial | Both sides simultaneously (no flipping needed) | Manual or Motorized | Growing apiaries (4+ hives) & Commercial operations |

| Manual | Varies (see above) | Hand-crank | Small-scale or remote beekeeping |

| Motorized | Varies (see above) | Electric motor | Beekeepers valuing time & efficiency |

Ready to scale your honey production efficiently?

As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides durable, high-capacity honey extractors designed for professional use. Our wholesale-focused operations ensure you get the right equipment to maximize your harvest and minimize labor.

Contact HONESTBEE today to discuss your extractor needs and get a quote tailored to your operation's scale.

Visual Guide

Related Products

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

People Also Ask

- What are the advantages of motorized extractors? Boost Honey Production and Save Time

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- What are the benefits of using an electric honey extractor? Boost Efficiency & Honey Yield for Your Apiary

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- How do automated honey extractors reduce physical strain for beekeepers? Boost Efficiency & Prevent Burnout