Choosing the right honey extractor is a pivotal decision for any beekeeper, directly impacting the efficiency and enjoyment of your harvest. The primary factors to consider are your production scale, the extractor's power source (manual vs. electric), its frame capacity, and the material it's made from, with stainless steel being the industry standard for durability and food safety.

Your choice of an extractor is fundamentally about aligning your equipment with your ambition. It’s a strategic investment that balances your current hive count against your future goals, with the right machine saving you hours of labor and preserving the quality of your hard-earned honey.

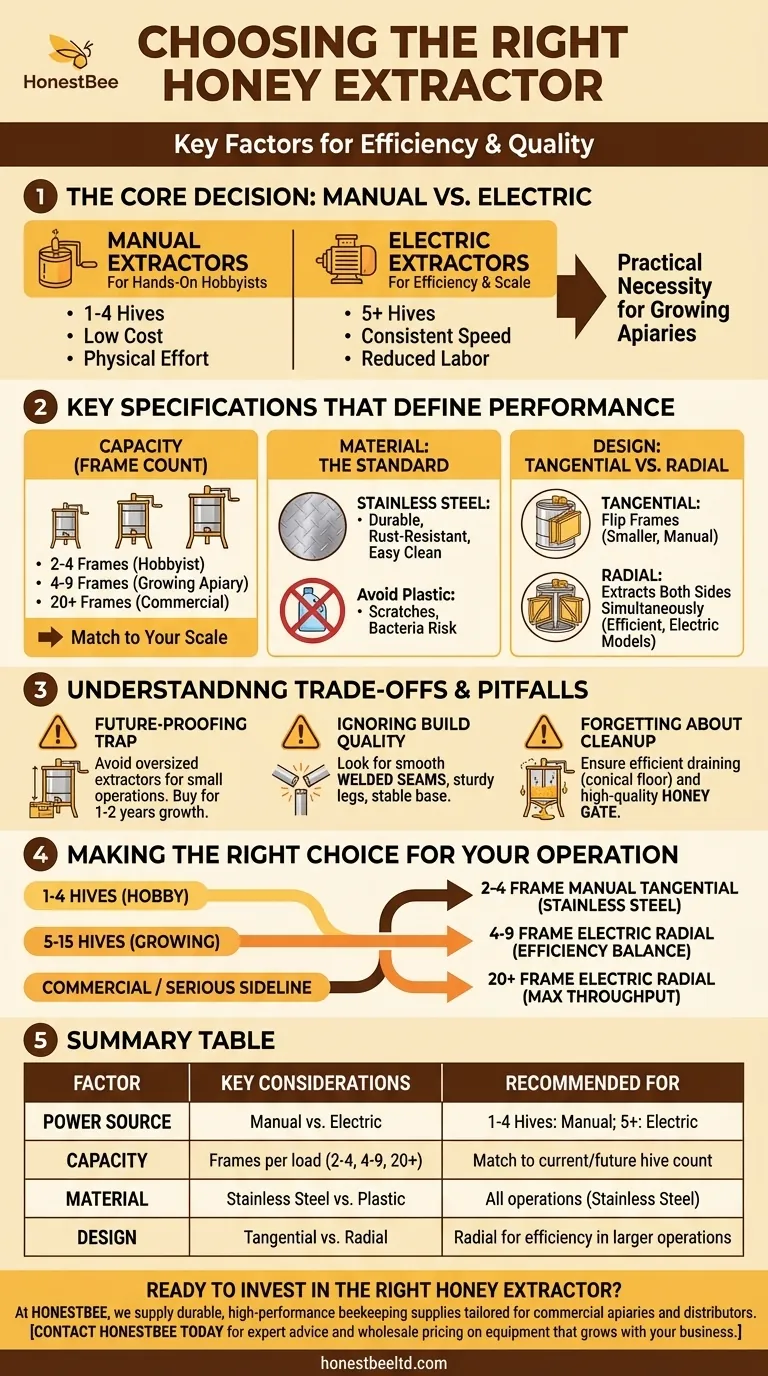

The Core Decision: Manual vs. Electric

The most significant choice you will make is between a manual, hand-cranked extractor and a motorized, electric one. This decision is driven almost entirely by the number of hives you manage.

Manual Extractors: For the Hands-On Hobbyist

Manual extractors are the entry point for most new beekeepers. They are operated with a hand crank, providing a simple, power-free method for honey extraction.

These models are best suited for beekeepers with one to four hives. While they are the most affordable option, be prepared for a significant physical effort. The process is slower and more labor-intensive than with an electric model.

Electric Extractors: For Efficiency and Scale

Electric extractors use a motor to spin the frames, dramatically reducing labor and speeding up the entire process. They offer consistent, controlled speeds which can result in more complete extraction without damaging combs.

An electric model becomes a practical necessity once you manage five or more hives. For any commercial or serious sideline operation, it is the only viable choice for handling a large volume of honey efficiently.

Key Specifications That Define Performance

Beyond the power source, the technical specifications of an extractor determine its throughput and longevity.

Extractor Capacity (Frame Count)

Capacity refers to the number of frames the machine can hold at one time. This directly correlates with the scale of your operation.

A 2-4 frame extractor is typical for hobbyists. A 4-9 frame model is an excellent choice for a growing apiary. Commercial operations will require extractors that can hold 20 or more frames to process harvests efficiently.

Material: Why Stainless Steel is the Standard

The material of the drum and basket is a critical factor for food safety and durability. Stainless steel is the preferred material because it is rust-resistant, will not absorb odors, and is extremely easy to clean and sanitize.

While cheaper plastic models exist, they can scratch easily, creating crevices where bacteria can grow. For the quality of your honey and the longevity of your equipment, food-grade stainless steel is a wise investment.

Design: Tangential vs. Radial

This is a crucial but often overlooked detail. A tangential extractor holds frames like spokes in a wheel, with one side of the comb facing out. You must manually flip the frames to extract honey from the second side. These are common in smaller, manual models.

A radial extractor positions frames so that centrifugal force extracts honey from both sides simultaneously. This design is far more efficient and is standard on nearly all larger electric models.

Understanding the Trade-offs and Pitfalls

Investing in an extractor is a significant expense. Avoiding common mistakes will ensure your money is well spent.

The "Future-Proofing" Trap

It can be tempting to buy a large, expensive extractor for your two hives, assuming you will grow into it. However, a large machine is often inefficient for a small number of frames, is harder to clean, and requires significant storage space. Buy for the apiary you have, or plan to have in the next 1-2 years.

Ignoring Build Quality

Not all stainless steel is created equal. Look for machines with smooth, welded seams rather than tacked or sealed joints, as they are stronger and easier to clean. Ensure the legs and base are sturdy and stable to prevent violent shaking during operation.

Forgetting About Cleanup

Extraction is a messy process. A well-designed extractor should have a conical floor that drains honey efficiently and a high-quality honey gate (valve) that doesn't leak. The easier it is to take apart and clean, the more likely you are to do it properly.

Making the Right Choice for Your Operation

Select your extractor based on a realistic assessment of your beekeeping goals.

- If your primary focus is managing 1-4 hives as a hobby: A 2-4 frame manual tangential extractor in stainless steel is your most cost-effective and practical starting point.

- If your primary focus is growing your apiary to 5-15 hives: An electric radial extractor with a capacity of 4-9 frames offers the best balance of efficiency and investment.

- If your primary focus is a commercial or serious sideline operation: A large-capacity (20+ frame) electric radial extractor is essential for maximizing throughput and minimizing labor costs.

Investing in the right extractor transforms a laborious chore into a satisfying conclusion to your beekeeping season.

Summary Table:

| Factor | Key Considerations | Recommended For |

|---|---|---|

| Power Source | Manual (hand-crank) vs. Electric (motorized) | 1-4 hives: Manual; 5+ hives: Electric |

| Capacity | Number of frames per load (e.g., 2-4, 4-9, 20+) | Match to your current/future hive count |

| Material | Stainless steel (durable, food-safe) vs. plastic | All operations for longevity and hygiene |

| Design | Tangential (flip frames) vs. Radial (extract both sides) | Radial for efficiency in larger operations |

Ready to Invest in the Right Honey Extractor for Your Apiary?

At HONESTBEE, we supply durable, high-performance beekeeping supplies and equipment tailored for commercial apiaries and beekeeping equipment distributors. Whether you're scaling your hobby or running a serious sideline operation, our wholesale-focused solutions ensure you get the right extractor—from manual starters to large-capacity electric models—that saves labor and protects your honey quality.

Contact HONESTBEE today for expert advice and wholesale pricing on equipment that grows with your business.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the main methods of honey extraction? Optimize Your Harvest for Maximum Yield

- What advantages do electric honey extractors have over manual ones? Boost Efficiency in Your Honey Harvest

- What technical advantages does a mechanical honey extractor provide? Maximize Yield and Preserve Hive Assets

- What are the advantages of centrifugal honey extractors? Boost Commercial Yield Through Comb Preservation

- What is the best way to clean an electric honey extractor after use? A Guide to Purity & Longevity

- What are the core advantages of using a centrifugal separator in the honey harvesting process? Boost Quality & Yield

- What are the main benefits of using a honey extractor? Maximize Yields and Protect Your Honeycomb

- What are common problems with honey extractors and their solutions? Troubleshooting Your Beekeeping Equipment