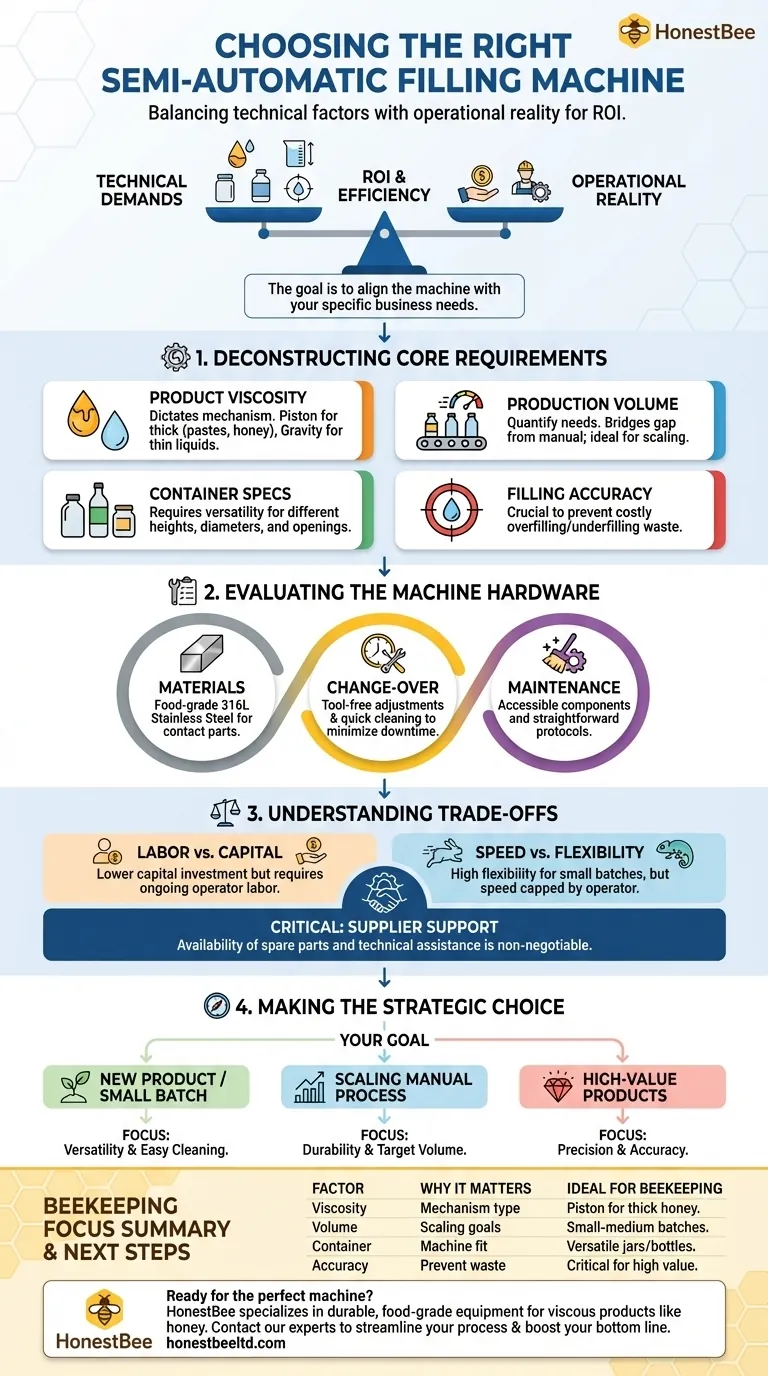

To select the right semi-automatic filling machine, you must evaluate four core factors: the physical properties of your product (especially its viscosity), your target production volume, the specifications of your containers, and the level of filling accuracy your operation requires. These elements work together to define the technical capabilities needed in a machine that will serve as a true asset, not a bottleneck.

The central challenge is not just finding a machine that works, but finding one that aligns with your specific operational reality. The ideal choice balances the technical demands of your product with the financial and labor constraints of your business, ensuring a return on investment through efficiency and reliability.

Deconstructing Your Core Requirements

A successful purchase begins with a deep analysis of your product and process. The machine is a tool, and you must first define the job it needs to do.

Factor 1: The Nature of Your Product (Viscosity)

The single most important technical factor is your product's viscosity, or its thickness and resistance to flow. A machine designed for water-thin liquids will fail to handle thick pastes like honey or creams.

Different mechanisms are required for different products. Piston fillers are excellent for viscous products, while gravity or overflow fillers are better suited for low-viscosity, free-flowing liquids.

Factor 2: Your Production Volume and Speed

You must quantify your needs. Are you filling hundreds of containers per day, or thousands? Be realistic about your current output and projected growth.

A semi-automatic machine is ideal for bridging the gap between manual filling and a fully automated line. It requires an operator but significantly boosts consistency and speed, making it perfect for small to medium-sized businesses aiming to scale.

Factor 3: Your Container's Size and Shape

The physical dimensions of your containers dictate the machine's setup. Consider the range of heights, diameters, and opening sizes you will use.

Look for a machine with versatility. The ability to easily adjust settings for different jar or bottle sizes without extensive downtime is critical for operations that handle multiple product SKUs.

Factor తెలిపారుThe Demand for Precision and Accuracy

Inaccurate fills are costly. Overfilling wastes product and cuts into profit margins, while underfilling can lead to customer complaints and regulatory issues.

Define your acceptable tolerance for fill volume variation. Machines with precise controls and reliable mechanisms ensure each container is filled consistently, protecting both your brand reputation and your bottom line.

Evaluating the Machine Itself

Once you have defined your needs, you can assess the hardware. Focus on build quality, operational flexibility, and long-term viability.

Material Compatibility and Construction

For any food, beverage, or cosmetic product, the machine must be constructed from food-grade materials. 316L stainless steel is the industry standard for contact parts due to its corrosion resistance and hygienic properties.

The overall build quality indicates durability. A robust, well-welded frame will withstand the rigors of a production environment far better than a flimsy one.

Versatility and Ease of Changeover

The time it takes to switch from one product or container to another is known as changeover time. This is non-productive downtime, and minimizing it is essential for efficiency.

Ask about tool-free adjustments and how easily the system can be purged and cleaned between runs. A machine that is fast to fill but slow to change over may not actually increase your total output.

Maintenance and Cleaning Protocols

Every machine requires maintenance. A well-designed filler will have easily accessible components and straightforward cleaning procedures.

Complex disassembly for daily cleaning creates a significant labor cost and increases the risk of error. This is a critical, yet often overlooked, aspect of total cost of ownership.

Understanding the Trade-offs

A semi-automatic system is a compromise by design. Understanding its inherent limitations is key to making an informed decision and avoiding mismatched expectations.

Labor Cost vs. Capital Investment

These machines are not "lights-out" automation. They require a dedicated operator to place containers, initiate the fill cycle, and move the finished product.

The investment is lower than a fully automatic line, but the ongoing labor cost remains a factor. You are trading a higher capital expense for a lower, but continuous, operational expense.

Speed vs. Flexibility

Semi-automatic fillers offer greater flexibility than their fully automated counterparts, making them ideal for small batches and frequent product changes.

However, their ultimate speed is capped by the efficiency of the human operator. They will never match the raw output of a fully integrated, automated packaging line.

The Importance of Supplier Support

A machine is only as good as the support behind it. The availability of spare parts, technical assistance, and after-sales service is non-negotiable.

A cheaper machine from a supplier with poor support can quickly become a liability. A single unavailable part can shut down your entire production process.

Making the Right Choice for Your Goal

Select a machine by matching its strengths to your primary business objective.

- If your primary focus is launching a new product or small-batch production: Prioritize a machine with excellent versatility and extremely easy cleaning protocols to handle frequent changeovers.

- If your primary focus is scaling an existing manual process: Focus on a durable machine that reliably meets your target production volume and is backed by strong supplier support.

- If your primary focus is high-value products requiring precision: Invest in a filler with verifiable accuracy and repeatable performance to minimize expensive product waste.

Choosing the right equipment is a strategic investment in your operational capacity and product quality.

Summary Table:

| Key Factor | Why It Matters | Ideal for Beekeeping Products |

|---|---|---|

| Product Viscosity | Determines the filling mechanism (e.g., piston for thick honey). | High-viscosity liquids like raw honey, creamed honey, and beeswax balms. |

| Production Volume | Matches machine speed to your output goals for scaling operations. | Small to medium batches; perfect for beekeepers and distributors expanding their lines. |

| Container Specs | Ensures the machine can handle your specific jar and bottle sizes. | Versatile adjustment for various honey jars, squeeze bottles, and tins. |

| Filling Accuracy | Prevents costly product waste from overfilling or underfilling. | Critical for high-value products to protect profit margins and brand reputation. |

Ready to find the perfect semi-automatic filling machine for your honey or beekeeping product operation?

At HONESTBEE, we specialize in supplying durable, food-grade equipment to commercial apiaries and beekeeping equipment distributors. We understand the unique challenges of handling viscous products like honey and can help you select a machine that ensures precision, minimizes waste, and grows with your business.

Contact our experts today for a personalized consultation and discover how the right equipment can streamline your filling process and boost your bottom line.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

People Also Ask

- What are the advantages of semi-automatic filling machines? Boost Production Speed & Versatility

- How do automated honey filling lines meet trade standards? Unlock Global Export Markets with HONESTBEE Precision

- What is the automated process of a jar or bottle packing machine for honey? Optimize Your Apiary Production

- What is the indirect impact of bee predators on honey filling equipment? Optimize ROI through supply chain stability.

- What are the basic components of a honey stick machine and their functions? Expert Guide to Key Parts

- What is the role of a high-precision honey filling machine? Boost Your Retail Packaging Efficiency and Compliance

- What are the advantages of using a food-grade syringe for filling honey straws? Precision and Hygiene for Apiaries

- How do industrial automatic honey-filling machines maintain quality? Secure Purity from Tank to Retail Shelf