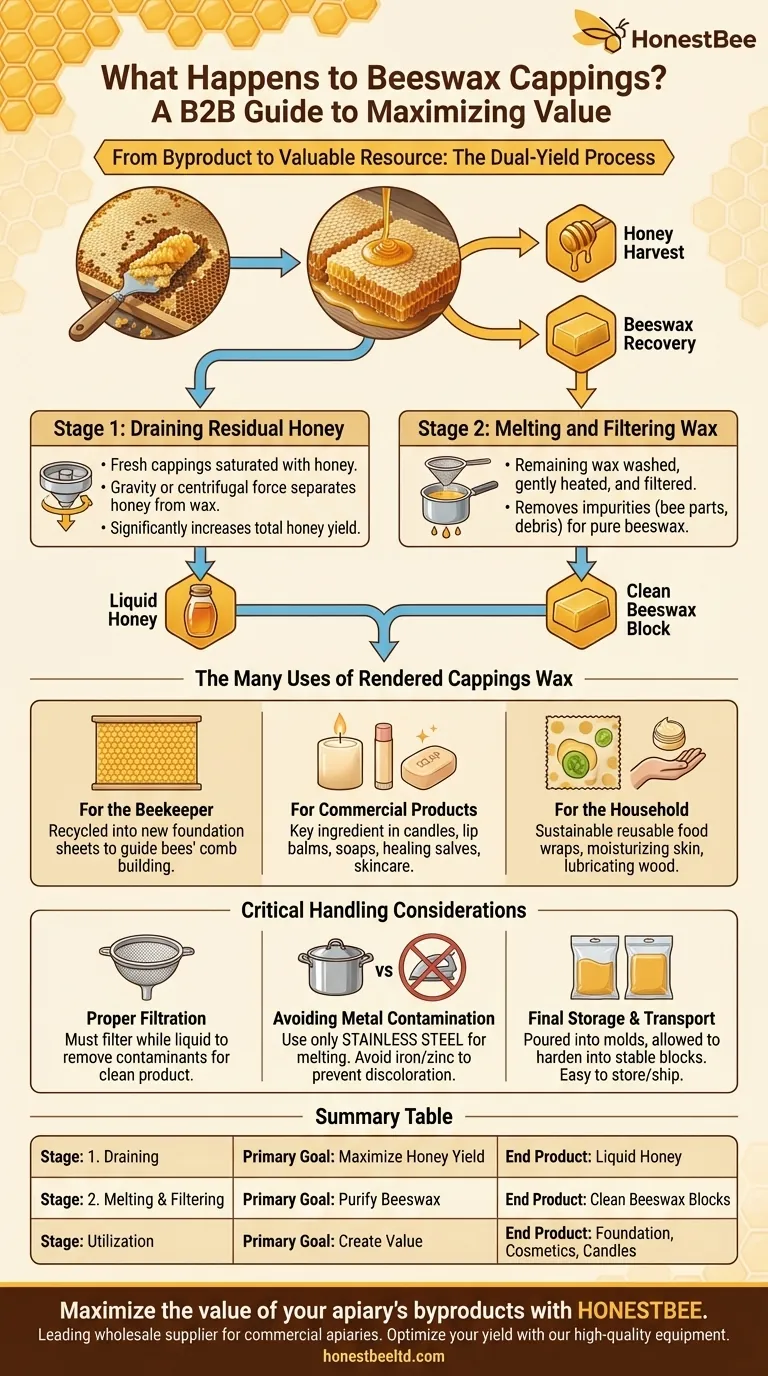

To be clear, beeswax cappings removed from honeycomb are a valuable resource, not waste. They are immediately processed in two stages: first, the residual honey is drained from them, and second, the wax itself is melted, filtered, and recycled into a variety of useful products.

The core principle is that cappings are a dual-yield byproduct. The process first maximizes the beekeeper's honey harvest and then recovers high-quality beeswax for reuse in the apiary or for creating commercial goods.

The Two-Stage Recovery Process

After a beekeeper slices the cappings off a frame of honey, the recovery process begins. This is designed to separate the two valuable components: the honey and the wax.

Stage 1: Draining the Residual Honey

The freshly cut cappings are saturated with honey. They are typically placed in a filter, strainer, or a dedicated cappings spinner.

Gravity (or centrifugal force) then pulls the honey away from the wax. This step is crucial as it significantly increases the beekeeper's total honey yield.

Stage 2: Melting and Filtering the Wax

Once most of the honey has been drained, the remaining wax is washed and then gently heated.

Melting serves two purposes: it separates the last bits of honey and allows the raw wax to be filtered. This filtering process removes impurities like bee parts or other debris, resulting in a clean block of pure beeswax.

The Many Uses of Rendered Cappings Wax

The clean, rendered beeswax from cappings is highly prized for its purity and light color. It becomes a raw material for numerous applications.

For the Beekeeper: New Foundation

A primary use within the beekeeping world is to recycle the wax into new foundation sheets. These sheets, embossed with a honeycomb pattern, are placed in frames to give bees a guide for building new comb.

For Commercial Products: Cosmetics and Candles

Beeswax is a key ingredient in many natural products. It's used to create candles, lip balms, soaps, healing salves, and other skincare items. Its unique properties provide structure and moisturizing benefits.

For the Household: Practical Applications

Beyond cosmetics, the processed wax can be used to make sustainable reusable food wraps. It also has simpler, direct uses, such as moisturizing skin, soothing itches, or even lubricating a stuck wooden drawer.

Critical Handling Considerations

Processing beeswax requires care to maintain its quality. Improper handling can easily ruin the final product.

The Importance of Proper Filtration

Simply melting the wax is not enough. It must be filtered while liquid to remove any solid contaminants. A clean final product is essential for most applications, especially in cosmetics.

Avoiding Metal Contamination

Beeswax reacts adversely with certain metals, particularly iron and zinc. Contact with these materials can discolor the wax and degrade its quality.

The only metal appropriate for melting, storing, or shipping beeswax is stainless steel.

Final Storage and Transport

After being melted and filtered, the wax is typically poured into molds and allowed to harden into blocks. These blocks are stable and easy to store or transport, often in simple Hessian bags.

Making the Right Choice for Your Goal

How you handle cappings depends entirely on what you want to achieve with them.

- If your primary focus is maximizing honey yield: The most critical step is thoroughly draining the cappings before doing anything else.

- If your primary focus is beekeeping efficiency: Recycling your own wax to create new foundation is a sustainable practice that reduces operational costs.

- If your primary focus is creating a value-added product: Rendering the wax into clean, filtered blocks creates a valuable raw material for high-demand goods like candles and natural cosmetics.

Ultimately, properly processing beeswax cappings transforms a simple byproduct into a significant asset.

Summary Table:

| Stage | Primary Goal | Key Action | End Product |

|---|---|---|---|

| 1. Draining | Maximize Honey Yield | Separate honey from wax via gravity/spinning | Liquid Honey |

| 2. Melting & Filtering | Purify Beeswax | Gently heat and filter impurities | Clean Beeswax Blocks |

| Utilization | Create Value | Recycle or sell the purified wax | Foundation, Cosmetics, Candles |

Maximize the value of your apiary's byproducts with HONESTBEE.

As a leading wholesale supplier for commercial apiaries and distributors, we understand that efficiency and profitability go hand-in-hand. Properly processing beeswax cappings is a key part of a sustainable and profitable operation.

HONESTBEE supplies the high-quality beekeeping equipment and supplies you need to efficiently handle every stage of the process, from honey extraction to wax rendering. Let us help you turn your cappings into a valuable asset.

Ready to optimize your yield? Contact our expert team today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Thermostatic Conical Honey Melter

People Also Ask

- What is the function of high-performance automatic uncapping devices? Streamline Your Honey Extraction Efficiency

- How does an uncapping plane work? Precision Honey Harvesting with Adjustable Blades for Beekeepers

- What to do with cappings after extracting honey? Maximize Your Harvest's Value

- What role do automatic uncapping machines play in honey processing lines? Boost Your Industrial Honey Yield

- What should beekeepers consider when choosing an uncapping method? Boost Honey Harvest Efficiency & Profitability

- How does the V-shape cutting position improve honeycomb uncapping efficiency? Unlock 100% Scraping Success

- What is honey uncapping? The Essential First Step to Harvest Your Honey

- How does an uncapping plane work and what is its main feature? Master Precision Harvesting with Adjustable Heat