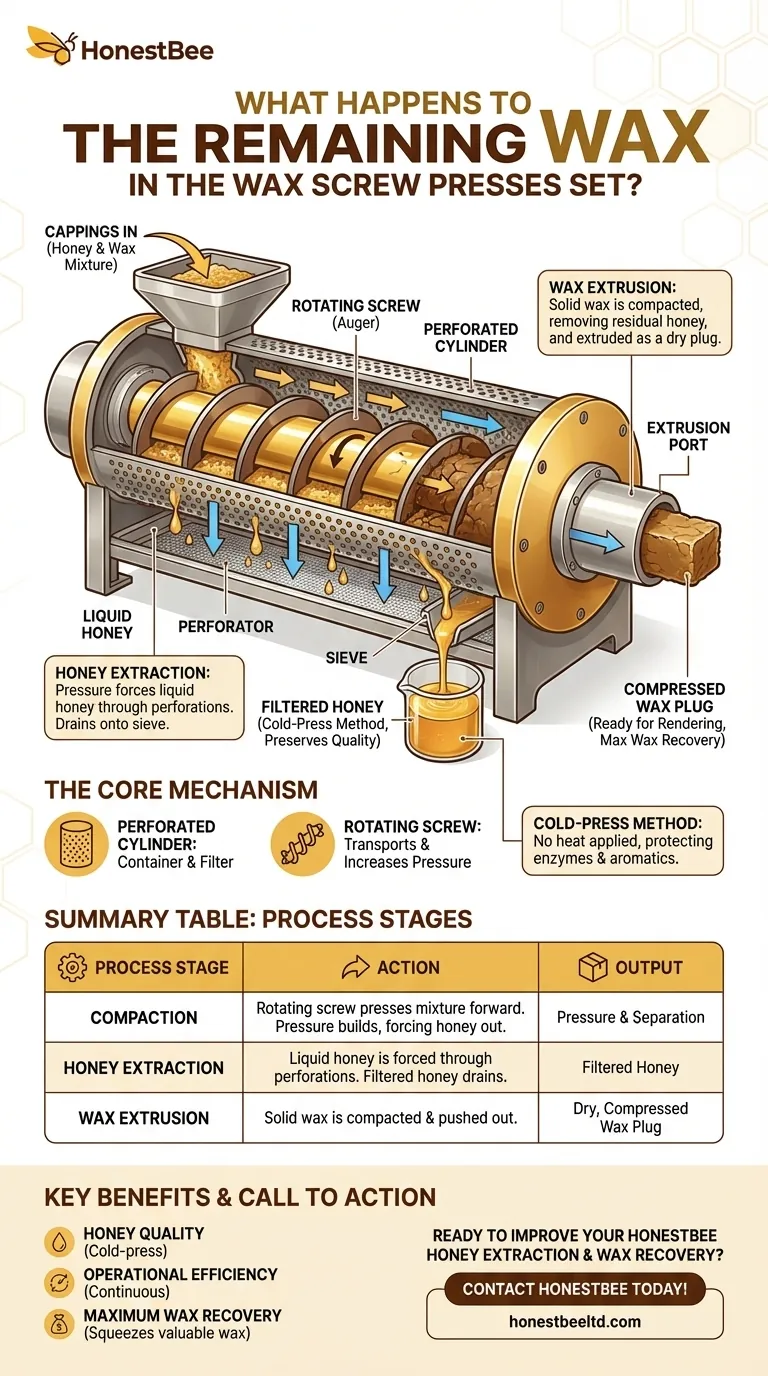

In a wax screw press, the remaining wax is continuously compacted and forced forward by a rotating internal screw. This action squeezes the liquid honey out through a perforated cylinder while extruding the compressed wax from the end of the machine as a solid plug.

The core function of a wax screw press is to use purely mechanical force to achieve a continuous separation of honey and wax cappings. It transforms a sticky mixture into two distinct and usable outputs: filtered, liquid honey and a compressed block of wax ready for rendering.

The Core Mechanism: How Separation Occurs

A wax screw press operates on a simple but highly effective principle of mechanical separation. The entire process takes place inside a single, robust unit designed for continuous throughput.

The Perforated Cylinder

The main body of the press is a perforated cylinder. This component acts as a strong container for the honey and wax mixture while also serving as the primary filter.

The Rotating Screw

Inside this cylinder is a central rotating screw, sometimes referred to as a worm or auger. As this screw turns, it performs two critical jobs simultaneously: it transports the material along the length of the cylinder and steadily increases pressure.

The Application of Force

The screw's design ensures that as the wax and honey move forward, the space they occupy decreases. This constant compression is what forces the liquid honey to separate from the solid wax.

Deconstructing the Process Step-by-Step

Understanding the journey of the material through the press clarifies how the two distinct outputs are created.

Honey Extraction

As pressure builds, the liquid honey is forced through the small orifices in the perforated cylinder and a surrounding steel plate. It can't be compressed, so it escapes through the path of least resistance.

This extracted honey then drains onto a sieve located below the cylinder, providing an initial stage of filtration before collection.

Wax Compaction and Extrusion

The solid wax cappings cannot pass through the small holes with the honey. Instead, the wax is continuously compacted and pushed forward by the screw.

This process removes a significant amount of residual honey, resulting in a relatively dry plug of wax being pushed out, or extruded, from the machine's exit port.

Key Operational Considerations

While efficient, the effectiveness of a wax screw press depends on understanding its design intent and limitations.

Designed for Cappings

These presses are specifically designed to process the mixture of honey and wax generated when uncapping frames, not for pressing honey directly from intact comb. The material must be able to flow and be compressed by the screw.

A Purely Mechanical Process

The separation is achieved without the application of heat. This cold-press method is crucial for preserving the natural quality, enzymes, and delicate aromatics of the honey.

Condition of the Outputs

The resulting honey is filtered and ready for final settling or bottling. The extruded wax is highly compressed and ready for the next stage of processing, which is typically melting and rendering into clean blocks.

Making the Right Choice for Your Goal

To best leverage a wax screw press, align its function with your primary operational objective.

- If your primary focus is honey quality: This machine excels by providing a cold-press method that protects the honey’s delicate properties from heat degradation.

- If your primary focus is operational efficiency: The press offers a continuous, automated process for handling cappings, which is a major bottleneck in many honey extraction workflows.

- If your primary focus is maximum wax recovery: The press effectively squeezes valuable wax from cappings, producing a compressed, easy-to-handle block that significantly increases your total wax yield.

By understanding this mechanical separation, you can efficiently process your cappings to yield high-quality honey and a valuable wax byproduct.

Summary Table:

| Process Stage | Action | Output |

|---|---|---|

| Compaction | Rotating screw presses mixture forward. | Pressure builds, forcing honey out. |

| Honey Extraction | Liquid honey is forced through perforations. | Filtered honey drains for collection. |

| Wax Extrusion | Solid wax is compacted and pushed out. | Dry, compressed wax plug is produced. |

Ready to improve your honey extraction and wax recovery?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance wax screw presses you need for a more efficient and profitable operation. Our equipment is designed for continuous throughput, protecting honey quality with a cold-press method and maximizing your wax yield.

Contact HONESTBEE today to find the right wax press for your commercial beekeeping needs!

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What are the operational characteristics of a basic manual honey press? Essential Guide for Artisanal Extraction

- What is the technical necessity of beeswax extractors? Unlock High-Value Beekeeping Byproducts for Global Markets

- What is the cleaning procedure for a stainless steel honey press? Ensure Food Safety with These Pro Cleaning Steps

- What are the other applications for a honey press besides honey extraction? Maximize Your Multi-Purpose Harvest Tools

- What is the purpose of variable pressure control in a honey press? Mastering Quality and Yield

- Why is it critical to maintain the water temperature between 92°C and 95°C during beeswax extraction? Protect Wax Quality

- How do you operate a bucket honey press? A Step-by-Step Guide for Efficient Extraction

- What design features make the Honey Press user-friendly? Unlock Effortless Honey Extraction