At its core, a bottle capping machine performs a simple, critical function: it secures a cap onto a container to create a seal. This process generally involves two key stages: placing the cap onto the container's opening and then applying the necessary force—whether it's torque for a screw cap or pressure for a press-on lid—to tighten and seal it. This action protects the product from contamination, prevents leakage, and ensures its integrity until it reaches the end user.

A capping machine is not just a device for tightening lids; it is a crucial control point in a packaging line that guarantees product safety, consistency, and brand quality. Understanding its function is key to understanding modern manufacturing.

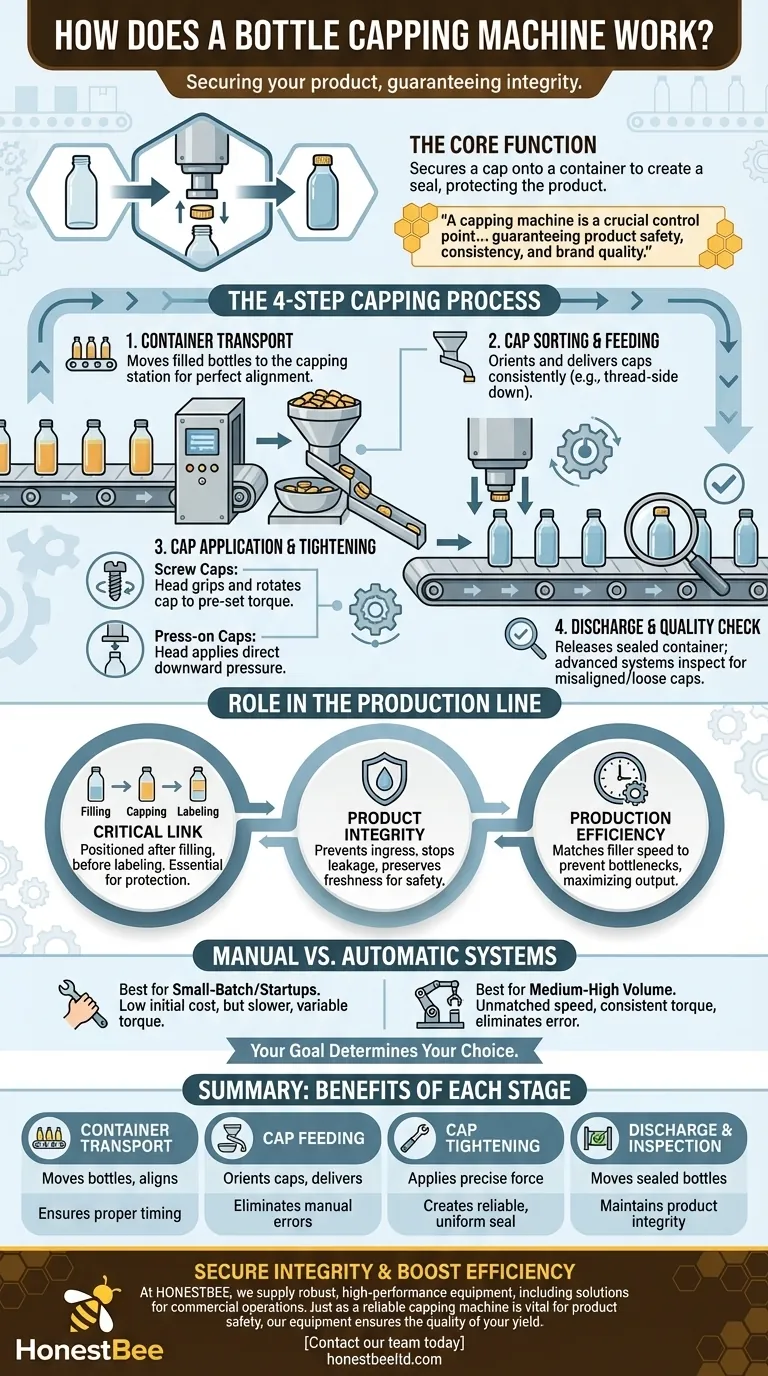

The Core Capping Process: A Step-by-Step Breakdown

While designs vary, the automated capping process follows a logical sequence to move from an open container to a sealed product ready for the next stage.

Step 1: Container Transport

Before capping, containers are typically filled with product. They then travel on a conveyor belt, which transports them in an orderly fashion to the capping station. Proper spacing and timing are critical to ensure each bottle aligns perfectly under the capping head.

Step 2: Cap Sorting and Feeding

For an automated process to work, caps must be delivered to the container consistently and in the correct orientation. This is handled by a cap feeder, often a large hopper connected to a sorting bowl or elevator. This system orients each cap (e.g., thread-side down) and sends it down a chute to be picked up and placed on the bottle.

Step 3: Cap Application and Tightening

This is the central action of the machine. Once a bottle is in position and a cap is ready, a capping head descends. For screw caps, the head (often called a chuck) grips the cap and rotates it to a pre-set torque, ensuring a tight but not over-tightened seal. For press-on caps, the head applies direct downward pressure to snap the lid into place.

Step 4: Discharge and Quality Check

After the cap is secured, the sealed container is released from the capping station and moves down the conveyor. It proceeds to the next phase of the packaging process, which is often labeling or case packing. Some advanced systems include immediate post-capping inspection to detect misaligned or loose caps.

The Capping Machine's Role in a Production Line

A capping machine does not operate in isolation. It is an integral part of a larger, interconnected system designed for efficiency and quality control.

A Critical Link in the Chain

The capping station is strategically positioned after filling and before labeling. This sequence is logical and universal. You must seal the product immediately after filling to protect it, and you must cap the bottle before labeling to avoid damaging the label during the capping process.

Ensuring Product Integrity

The primary purpose of capping is to protect the contents. A proper seal prevents oxygen and microbial ingress, stops product leakage, and preserves freshness and shelf life. For industries like pharmaceuticals and food and beverage, a perfect seal is non-negotiable for safety and regulatory compliance.

Maintaining Production Efficiency

In any high-volume operation, the capping machine must match the speed of the filler to prevent a bottleneck. An efficient, reliable capper ensures the entire packaging line runs smoothly and at its maximum rated speed, directly impacting overall output and cost-effectiveness.

Understanding the Trade-offs: Manual vs. Automatic

The references note that caps can be placed manually or automatically. This choice represents a fundamental trade-off between cost, speed, and consistency.

The Case for Manual and Semi-Automatic Systems

For small businesses, startups, or lines with very low volume, a fully automatic capper is often unnecessary. Handheld capping tools or simple semi-automatic machines (where an operator places the bottle) offer a low initial investment. However, they are slower and the tightness of the seal (torque) can vary between operators.

The Power of Automatic Systems

For any medium- to high-volume production, an automatic capping machine is essential. It delivers unmatched speed and, most importantly, consistency. By applying the exact same torque or pressure to every single container, it eliminates human error and guarantees a uniform, reliable seal, which is critical for brand reputation.

Making the Right Choice for Your Goal

Selecting the right capping strategy depends entirely on your operational scale and quality requirements.

- If your primary focus is launching a new product or small-batch production: A manual or semi-automatic capper provides the lowest initial cost and sufficient capability for limited runs.

- If your primary focus is scaling up to meet higher demand: An automatic capping machine is the only way to achieve the speed and consistency required without creating a major production bottleneck.

- If your primary focus is absolute product safety and consistency: An automatic capper with torque monitoring is your best investment to ensure every seal is perfect and verifiable.

Ultimately, the right capping process is a foundational element that protects your product, your efficiency, and your brand's promise to the customer.

Summary Table:

| Stage | Key Function | Benefit |

|---|---|---|

| Container Transport | Moves filled bottles to the capping station | Ensures proper alignment and timing |

| Cap Feeding | Orients and delivers caps consistently | Eliminates manual handling errors |

| Cap Tightening | Applies precise torque or pressure | Creates a reliable, uniform seal every time |

| Discharge & Inspection | Moves sealed bottles to the next stage | Maintains product integrity and line flow |

Ready to secure your product's integrity and boost your packaging line's efficiency?

At HONESTBEE, we supply robust, high-performance beekeeping supplies and equipment, including solutions for commercial apiaries and distributors. Just as a reliable capping machine is vital for product safety, our equipment is designed to ensure the health of your hives and the quality of your yield.

Let's discuss how our wholesale-focused operations can support your business's growth and consistency. Contact our team today to find the right equipment for your needs!

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Honey Frame Uncapper Machine for Beekeeping

- Lightweight Plastic Uncapping Roller with Tines

- Professional Stainless Steel Uncapping Fork with Wooden Handle

- Adjustable Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

People Also Ask

- What are the different types of capping machines available? Choose the Right One for Your Production Scale

- What is the function of a capping machine in honey packaging? Secure Your Product Quality and Shelf Life

- What is the working principle of bottle packing machine? Achieve Efficient, Automated Filling

- What are the main types of caps supported by bottle capping equipment? Threaded, Press-On, and Insertion

- What types of caps can capping machines handle? Find the Right Solution for Your Bottling Line

- What is the purpose of a bottle capping machine? Boost Efficiency and Ensure Product Integrity

- What are the categories of bottle capping machines? Choose the Right Automation for Your Line

- Can you bottle honey right after extraction? Weighing Speed vs. Quality for Your Apiary