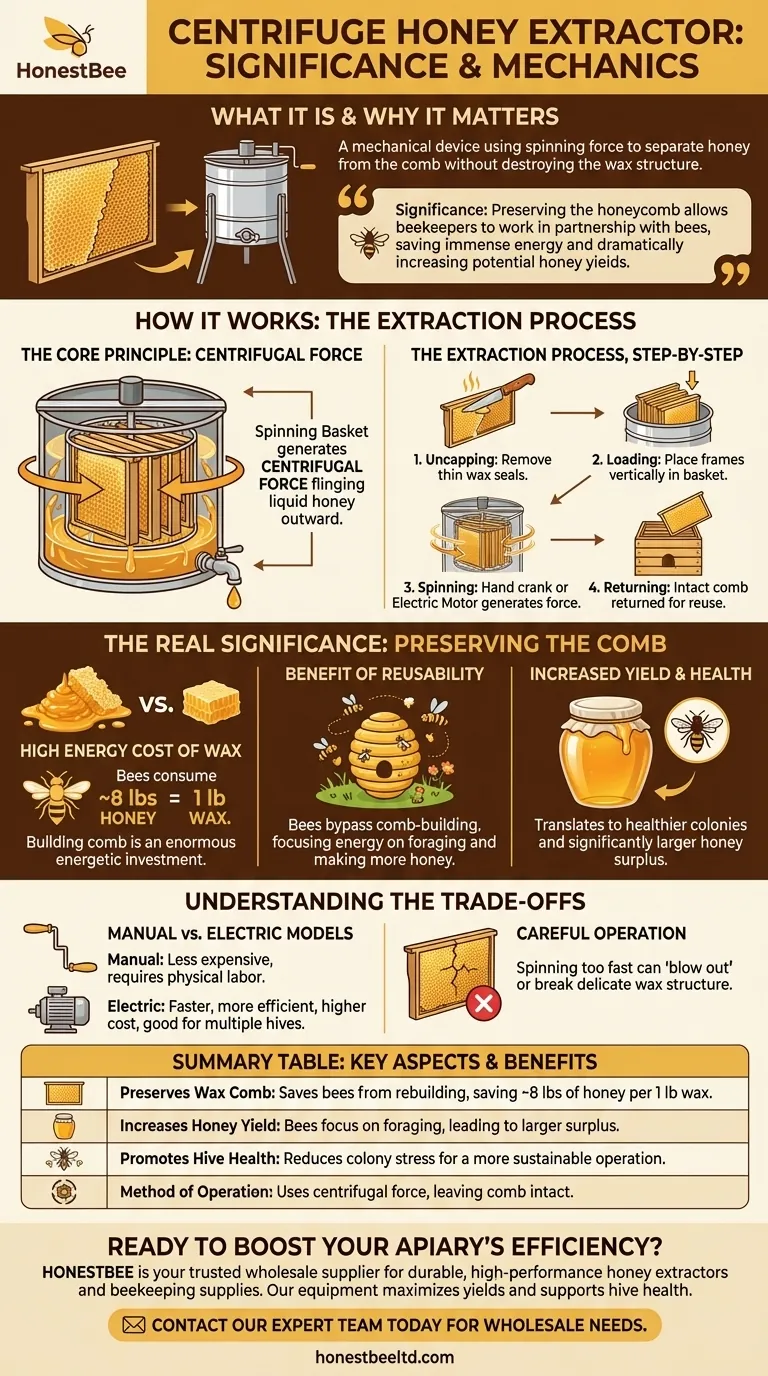

At its core, a centrifuge honey extractor is a mechanical device that uses spinning force to pull honey from the comb. This tool is standard in modern beekeeping because it separates the honey without destroying the delicate wax structure, a key advantage for both the bees and the beekeeper.

The true significance of a centrifuge extractor isn't just its speed or efficiency; it's that by preserving the honeycomb, it allows beekeepers to work in partnership with their bees, saving the colony immense energy and dramatically increasing potential honey yields.

How a Centrifuge Extractor Works

Understanding the mechanism reveals why this tool is so effective. It leverages a simple principle of physics to perform a delicate task.

The Core Principle: Centrifugal Force

A honey extractor is essentially a large drum with a basket inside that holds the honey frames. When the basket is spun at high speed, centrifugal force flings the liquid honey outward from the cells of the comb.

The honey hits the inner wall of the drum, drips down to the bottom, and can then be drained through a tap, leaving the wax comb intact.

The Extraction Process, Step-by-Step

The process is methodical and designed to be as gentle as possible on the comb.

- Uncapping the Comb: First, the beekeeper uses a heated knife or a special fork to carefully slice off the thin wax cappings that bees build to seal the honey in each cell.

- Loading the Extractor: The uncapped frames are then placed vertically inside the extractor's basket.

- Spinning the Frames: The extractor is spun, either by a hand crank or an electric motor. This generates the force needed to empty the cells.

- Returning the Comb: Once empty, the frames containing the undamaged "drawn" comb are returned to the hive. The bees can immediately clean them and begin refilling them with new honey.

The Real Significance: Preserving the Comb

The ability to reuse the comb is the single most important advantage of a centrifuge extractor and is a fundamental concept in sustainable beekeeping.

The High Energy Cost of Wax

Bees must consume a significant amount of nectar or honey—estimates often suggest around 8 pounds—to produce just one pound of wax. Building an entire hive's worth of comb is an enormous energetic investment for the colony.

The Benefit of Reusability

When beekeepers return empty, intact combs to the hive, the bees can bypass the entire comb-building process. This allows them to dedicate their full energy and resources to foraging for nectar and making more honey.

Increased Honey Yield and Hive Health

This energy savings translates directly into a healthier, more productive colony and a much larger honey surplus for the beekeeper. The hive isn't forced to constantly start from scratch, leading to a more efficient and sustainable operation.

Understanding the Trade-offs

While highly effective, a centrifuge extractor represents a specific choice with its own considerations.

Initial Investment

Compared to the simple "crush and strain" method, where the entire comb is destroyed, a mechanical extractor is a significant financial investment, especially for new hobbyists.

Manual vs. Electric Models

Manual extractors are less expensive but require physical labor to operate. Electric extractors are faster and more efficient but come at a higher cost, making them better suited for beekeepers with multiple hives.

The Need for Careful Operation

Even with an extractor, it is possible to damage combs. Spinning the frames too fast, especially when they are heavy with honey, can cause the delicate wax structure to "blow out" or break.

Making the Right Choice for Your Goal

Selecting the right extraction method depends entirely on the scale and goals of your beekeeping.

- If your primary focus is a single hobby hive: You can start with the crush-and-strain method, but recognize you are resetting your bees' progress each time.

- If your primary focus is efficiency and hive productivity: A centrifuge extractor is a non-negotiable tool that pays for itself in increased honey yields and healthier bees.

Ultimately, investing in a honey extractor is an investment in your hive's long-term success.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Preserves Wax Comb | Saves bees from rebuilding comb, saving ~8 lbs of honey per 1 lb of wax. |

| Increases Honey Yield | Bees focus on foraging, not construction, leading to a larger surplus. |

| Promotes Hive Health | Reduces colony stress, creating a more sustainable and productive operation. |

| Method of Operation | Uses centrifugal force to spin honey out of frames, leaving comb intact. |

Ready to boost your apiary's efficiency and honey production?

As a trusted wholesale supplier to commercial apiaries and equipment distributors, HONESTBEE provides the durable, high-performance honey extractors and beekeeping supplies you need to scale your operation sustainably. Our equipment is designed for productivity, helping you maximize yields and support hive health.

Contact our expert team today to discuss your wholesale needs and discover the right extraction solution for your business.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the advantages of automatic honey extractors? Scale Your Apiary with Unmatched Efficiency

- How long does it take to extract honey with an electric extractor? Automate Your Harvest for Greater Efficiency

- What are the advantages of electric honey extractors? Boost Efficiency for Your Commercial Apiary

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed