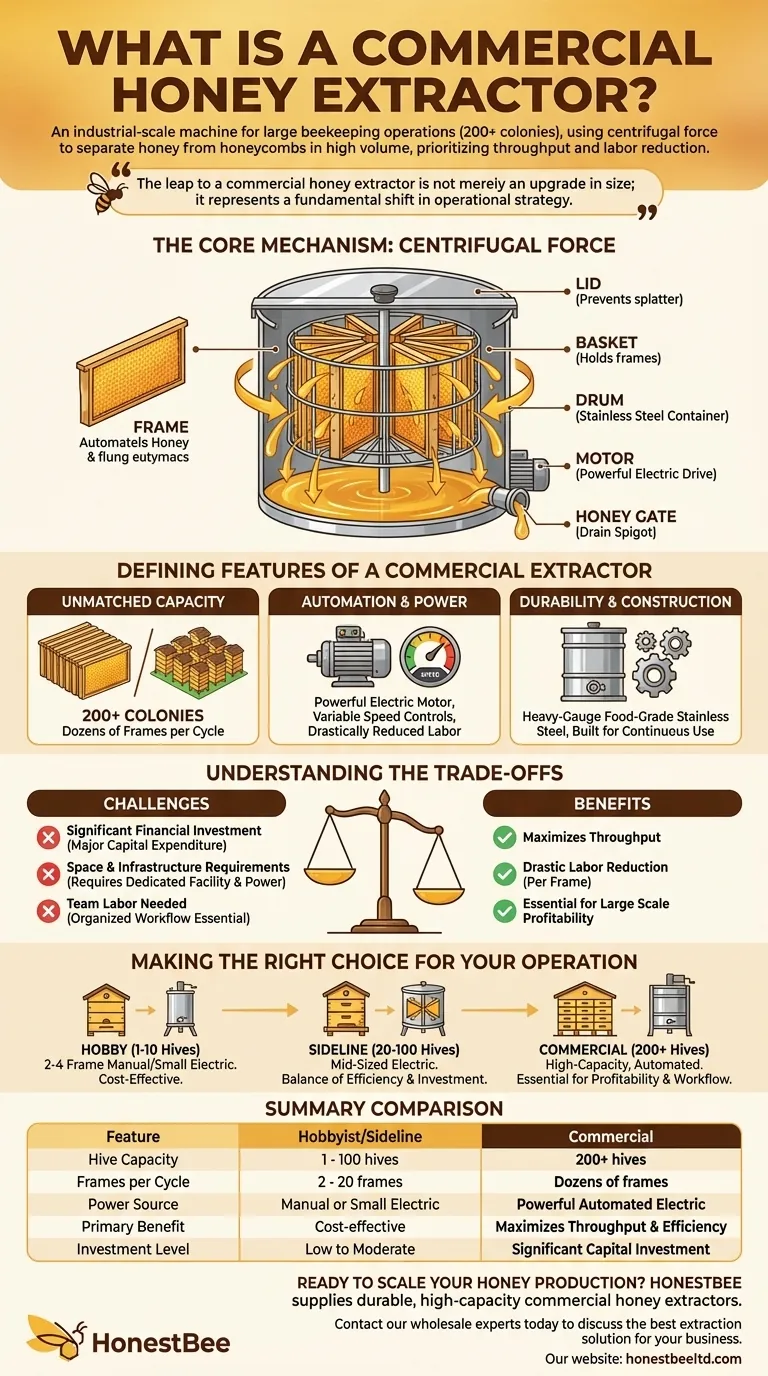

In essence, a commercial honey extractor is an industrial-scale machine designed for large beekeeping operations. It functions by using centrifugal force to separate honey from the honeycombs, but it is built to handle a significantly higher volume of frames than hobbyist models, making it a cornerstone piece of equipment for businesses with hundreds of colonies.

The leap to a commercial honey extractor is not merely an upgrade in size; it represents a fundamental shift in operational strategy, prioritizing high-throughput efficiency and labor reduction over the lower initial cost of smaller units.

How Any Honey Extractor Fundamentally Works

Before detailing what makes an extractor "commercial," it's crucial to understand the universal principle behind all of them. The core function is simple and elegant, relying on basic physics.

The Core Mechanism: Centrifugal Force

At its heart, a honey extractor is a centrifuge. Frames of uncapped honeycomb are placed inside a drum and spun at high speed. This rotation creates a strong centrifugal force that flings the liquid honey outwards from the comb's cells.

The honey strikes the inner wall of the drum, runs down to the bottom, and collects. From there, it can be drained through a tap or gate.

Key Components of the System

Virtually all modern extractors share a common set of components that work in concert to achieve this process.

- The Drum: This is the large, cylindrical outer container that holds everything.

- The Basket: A rack or cage inside the drum holds the honey frames securely in place during spinning.

- The Motor: An electric motor (or a hand crank on manual models) drives the rotation of the basket.

- The Lid: A cover prevents honey from splattering out of the drum during extraction.

- The Honey Gate: A spigot or valve at the bottom of the drum allows the collected honey to be drained.

The Defining Features of a "Commercial" Extractor

The primary distinction between a hobbyist and a commercial extractor is scale. This difference manifests in capacity, automation, and construction, all geared toward maximizing efficiency in a large operation.

Unmatched Capacity

A commercial extractor is defined by its ability to process a massive number of frames at once. While a small extractor might hold 2 to 4 frames, a commercial unit is designed for operations with 200 or more colonies, capable of holding dozens of frames per cycle.

Automation and Power

These machines are exclusively electric. The process is automated with a powerful motor and variable speed controls, allowing the operator to start the spin slowly to avoid damaging the delicate combs before ramping up to full extraction speed. This drastically reduces physical labor and processing time per frame.

Durability and Construction

Given the high-volume workload, commercial extractors are built for durability. They are typically made from heavy-gauge, food-grade stainless steel to withstand constant use, heavy loads, and rigorous cleaning season after season.

Understanding the Trade-offs

While powerful, a commercial extractor is not the right tool for every beekeeper. The benefits of scale come with significant practical and financial considerations.

The Significant Financial Investment

The most immediate barrier is cost. A commercial extractor represents a major capital expenditure, often costing many thousands of dollars more than a hobbyist or sideline model. This investment is only justifiable at a certain scale of production.

Space and Infrastructure Requirements

These are large, heavy machines that demand significant floor space in a dedicated processing facility, often called a "honey house." They also require a robust and reliable electrical supply to power their large motors.

Labor Efficiency vs. Labor Need

While a commercial extractor makes the work of one or two people far more efficient, the overall operation still requires a team. The sheer volume of frames that need to be uncapped, loaded, unloaded, and moved necessitates a well-organized workflow to keep the machine running continuously.

Making the Right Choice for Your Operation

Selecting the correct extractor is about accurately matching the equipment's capacity to the scale of your beekeeping.

- If your primary focus is hobby beekeeping (1-10 hives): A small, 2-4 frame manual or simple electric extractor is perfectly adequate and cost-effective.

- If you are a growing sideline beekeeper (20-100 hives): A mid-sized electric radial extractor offers the best balance of efficiency and manageable investment.

- If you manage a commercial operation (200+ hives): The investment in a high-capacity, automated commercial extractor becomes essential for profitability and sustainable workflow.

Ultimately, choosing the right extractor is a direct reflection of your operational goals and a critical decision for efficient honey harvesting.

Summary Table:

| Feature | Hobbyist/Sideline Extractor | Commercial Extractor |

|---|---|---|

| Hive Capacity | 1 - 100 hives | 200+ hives |

| Frames per Cycle | 2 - 20 frames | Dozens of frames |

| Power Source | Manual or small electric motor | Powerful, automated electric motor |

| Primary Benefit | Cost-effective for small scale | Maximizes throughput & labor efficiency |

| Investment Level | Low to Moderate | Significant capital investment |

Ready to Scale Your Honey Production?

If you manage a commercial apiary or are a beekeeping equipment distributor, the right extractor is critical for your profitability. HONESTBEE supplies durable, high-capacity commercial honey extractors and beekeeping equipment designed for the demands of large-scale operations.

Contact our wholesale experts today to discuss the best extraction solution for your business and see how we can support your growth.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

People Also Ask

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- What are the main types of honey extractor machines available? Choose the Right Extractor for Your Apiary's Scale

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort