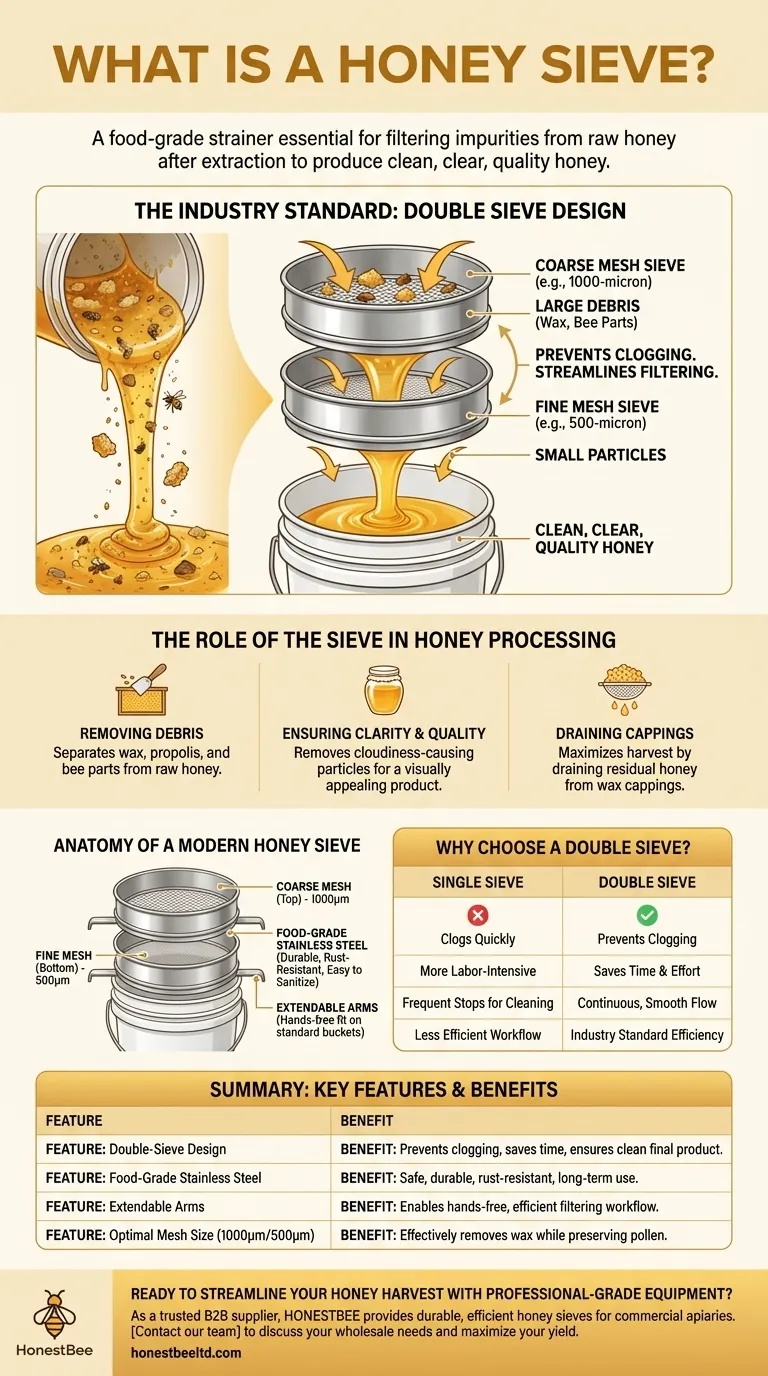

In short, a honey sieve is a food-grade strainer used to filter impurities from raw honey after it has been extracted from the comb. It is a fundamental tool for any beekeeper who wants to produce clean, clear honey free of debris like wax particles, wood splinters, and bee parts. The most effective models use a two-stage filtering process to ensure efficiency and quality.

The critical distinction to understand is between a simple strainer and a double sieve. While any filter can clean honey, the double-sieve design—with a coarse mesh stacked on top of a fine one—is the industry standard because it prevents clogging and streamlines the entire filtering process.

The Role of the Sieve in Honey Processing

A honey sieve, also called a honey strainer, is not optional if your goal is to produce honey that looks and feels like the finished product customers expect. Its role is straightforward but essential.

Removing Debris After Extraction

Raw honey, fresh from the extractor, contains a variety of natural impurities. These include bits of beeswax from uncapped cells, propolis, and occasionally even bee parts. A sieve's primary job is to physically separate this debris from the liquid honey.

Ensuring Honey Clarity and Quality

Filtering removes the larger particles that make raw honey appear cloudy. This process results in the clean, light-colored, and visually appealing honey that is ready for bottling. Unfiltered honey may also ferment faster due to the presence of foreign material.

A Second Use: Draining Cappings

The sieve has another practical application in the honey house. After slicing the wax cappings off the frames, a significant amount of honey remains mixed with the wax. Beekeepers often place these cappings into the sieve over a bucket to let the residual honey slowly drain out, maximizing their harvest.

Anatomy of a Modern Honey Sieve

While the concept is simple, modern honey sieves have specific design features optimized for the task. The most common and effective type is the double sieve.

The Double-Sieve System

This design is the key to efficient filtering. It consists of two stacking stainless steel strainers.

The top sieve has a coarse mesh (e.g., 1000-micron) designed to catch large debris like chunks of wax and dead bees. This initial pass prevents the larger particles from immediately clogging the finer filter below.

The bottom sieve has a fine mesh (e.g., 500-micron) that removes smaller particles, resulting in exceptionally clean honey. Because the large debris has already been removed, the honey flows through this finer screen more easily.

Material and Construction

Reputable honey sieves are made from food-grade stainless steel. This material is critical because it is durable, resistant to rust and corrosion from the natural acidity of honey, and easy to sanitize between uses.

Practical Design Features

Most double sieves include extendable arms. These adjustable supports allow the strainer to rest securely over the top of a standard 5-gallon bucket or honey pot, enabling a hands-free and "set it and forget it" workflow.

Understanding the Trade-offs

Choosing and using a honey sieve involves a few key considerations that impact your efficiency and final product.

Single vs. Double Sieves

A single, fine-mesh sieve is an option, but it will clog very quickly with raw, unfiltered honey. This forces you to constantly stop and scrape the wax and debris off the screen. A double sieve is a far more efficient system that saves significant time and effort.

Mesh Size and Filtration Speed

Honey is thick and viscous, so filtering it is a slow process. The finer the mesh, the slower the honey will drain through it. Temperature plays a huge role; honey flows much faster when it is warm (around 95°F / 35°C), so many beekeepers work in a heated room.

Filtering and Pollen

Extremely fine filters (in the sub-200-micron range, often used in commercial packing) can remove some pollen grains from the honey. While this creates a very clear product, many consumers of local, raw honey prefer it to contain its natural pollen. A standard double sieve generally strikes a good balance, removing debris without stripping the pollen.

Making the Right Choice for Your Goal

Selecting the right equipment comes down to the scale of your beekeeping operation and your primary goal.

- If your primary focus is harvesting for the first time: A standard stainless steel double sieve is the most practical and cost-effective investment you can make for producing high-quality honey.

- If your primary focus is scaling up your operation: Consider a larger diameter sieve or a dedicated honey tank with an integrated gate and filter system to handle higher volumes more efficiently.

- If your primary focus is minimal processing: You can get by with a single coarse strainer, but be prepared for a cloudier product and a more labor-intensive filtering process.

Ultimately, a quality honey sieve is the bridge between the raw harvest from the hive and the beautiful, clean honey you can proudly share or sell.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Double-Sieve Design | Coarse mesh (top) catches large debris; fine mesh (bottom) polishes honey. | Prevents clogging, saves time, and ensures a clean final product. |

| Food-Grade Stainless Steel | Durable, rust-resistant, and easy to sanitize. | Safe for food contact and built for long-term use in a honey house. |

| Extendable Arms | Adjustable supports fit securely over standard 5-gallon buckets. | Enables a hands-free, efficient filtering workflow. |

| Optimal Mesh Size | Typically 1000-micron (coarse) and 500-micron (fine). | Effectively removes wax and debris while preserving desirable honey pollen. |

Ready to streamline your honey harvest with professional-grade equipment?

As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, efficient honey sieves and beekeeping supplies you need to scale your operation and maximize your yield. Our equipment is designed for the demands of high-volume honey processing.

Contact our team today to discuss your needs and discover how our wholesale solutions can benefit your business.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality

- What are the functions and advantages of using honey strainers? Ensure Purity & Quality in Your Harvest

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life