At its core, a stainless steel sieve is a specialized tool used for precise particle separation and size analysis. It is specifically designed for applications where durability, resistance to corrosion, and prevention of sample contamination are non-negotiable requirements. The choice of stainless steel is deliberate, ensuring the sieve maintains its structural integrity and accuracy over time, even in demanding environments.

The decision to use a stainless steel sieve is driven by the need for reliable and repeatable results. Its material properties—durability, corrosion resistance, and inertness—safeguard the integrity of the analysis, making it the standard in scientific and industrial quality control.

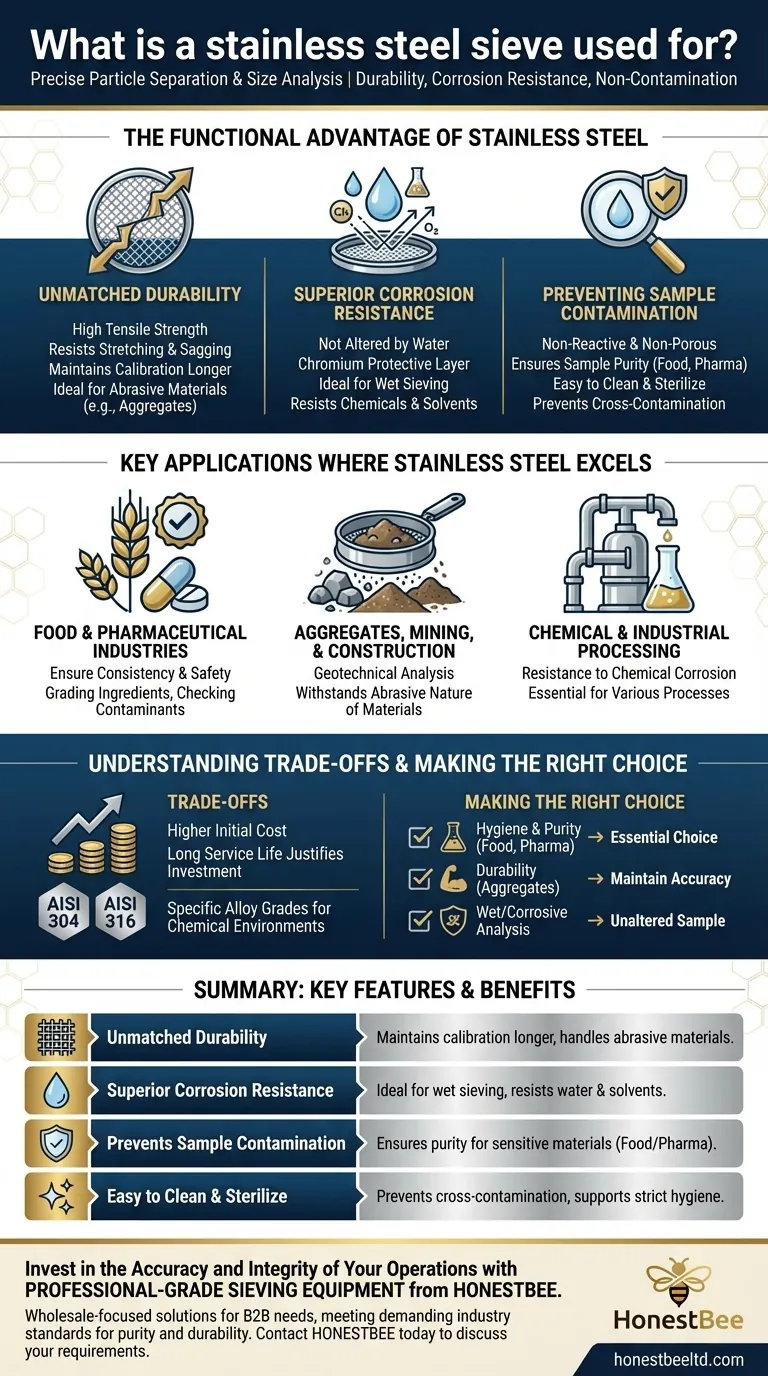

The Functional Advantage of Stainless Steel

Any sieve separates particles, but the material it's made from dictates its suitability for a specific task. Stainless steel offers a unique combination of properties that make it superior for a wide range of critical applications.

Unmatched Durability

A sieve's accuracy depends on its mesh openings remaining consistent. Stainless steel provides high tensile strength, ensuring the woven wire mesh resists stretching, sagging, or tearing, even when handling heavy or abrasive materials like mineral aggregates.

This structural robustness means the sieve maintains its calibration for longer, leading to more reliable and consistent measurement over its lifespan.

Superior Corrosion Resistance

Standard sieves made of materials like brass can corrode or oxidize when exposed to water or certain chemicals. Stainless steel is not altered by water, as it contains chromium which forms a passive, protective layer on its surface.

This makes it the ideal and often necessary choice for wet sieving, a process where water is used to help separate fine particles that might otherwise clump together.

Preventing Sample Contamination

In industries like food processing and pharmaceuticals, sample purity is paramount. The non-reactive and non-porous surface of stainless steel ensures that the sieve itself does not contaminate the material being tested.

Furthermore, its smooth surface is easy to clean and sterilize, preventing cross-contamination between different batches.

Key Applications Where Stainless Steel Excels

The properties of stainless steel make it the default choice in several demanding fields where accuracy and purity are critical.

Food and Pharmaceutical Industries

These industries rely on stainless steel sieves to ensure product consistency and safety. They are used for grading ingredients, checking for foreign contaminants, and ensuring final products meet strict particle size specifications.

Aggregates, Mining, and Construction

Professionals in these fields use stainless steel sieves for the geotechnical analysis of soil, gravel, and sand. The material's durability is essential for withstanding the highly abrasive nature of these materials without compromising the mesh's integrity.

Chemical and Industrial Processing

When working with various chemicals or in manufacturing processes, stainless steel provides the necessary resistance to chemical corrosion that would quickly degrade lesser materials.

Understanding the Trade-offs

While stainless steel is a superior material for many applications, it's important to understand its limitations to make a fully informed decision.

Higher Initial Cost

The primary trade-off is cost. Stainless steel sieves are typically more expensive than alternatives like brass or bronze. However, this higher initial investment is often justified by a longer service life and more reliable performance.

Specific Alloy Grades

The references mention AISI 304 and 316 stainless steel. While both are highly resistant, AISI 316 offers superior corrosion resistance, particularly against chlorides and other industrial solvents, but comes at an even higher price point. Understanding the specific chemical environment is key to choosing the correct grade.

Making the Right Choice for Your Goal

Selecting the correct sieve material is fundamental to achieving accurate and repeatable results.

- If your primary focus is hygiene and sample purity (food, pharma): Stainless steel is the essential choice to prevent contamination and allow for effective sterilization.

- If your primary focus is durability with abrasive materials (aggregates, mining): The strength of stainless steel is necessary to maintain mesh accuracy and extend the sieve's working life.

- If your primary focus is wet analysis or involves corrosive elements: The non-corrosive properties of stainless steel ensure the sieve and the sample remain unaltered during the process.

Ultimately, choosing a stainless steel sieve is an investment in the accuracy and integrity of your work.

Summary Table:

| Key Feature | Benefit for Your Application |

|---|---|

| Unmatched Durability | Maintains calibration longer, even with abrasive materials like sand and aggregates. |

| Superior Corrosion Resistance | Ideal for wet sieving and chemical processing; resists water and solvents. |

| Prevents Sample Contamination | Non-reactive, non-porous surface ensures purity for food, pharmaceutical, and sensitive materials. |

| Easy to Clean & Sterilize | Smooth surface prevents cross-contamination, supporting strict hygiene protocols. |

Invest in the accuracy and integrity of your operations with professional-grade sieving equipment from HONESTBEE.

Whether you are a commercial apiary requiring precise pollen grading or a beekeeping equipment distributor sourcing durable tools for your clients, our wholesale-focused operations provide the reliable, high-performance stainless steel sieves you need. We supply the equipment that meets the demanding standards of industries where purity and durability are critical.

Contact HONESTBEE today to discuss your specific requirements and learn how our sieving solutions can enhance your quality control processes.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Cabinet Bottle Dryer

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What is the function of a professional stainless steel hive tool in IFB? Optimize Your Colony Strength Assessment

- Which technical challenges in hive maintenance are addressed by using a professional stainless steel hive tool?

- What are the primary functions of a stainless steel hive tool? Essential Equipment for Professional Beekeeping

- What are the specific applications of a beekeeping chisel? Master Hive Maintenance with Precision Tools

- How does the hive splitting process contribute to colony management? Master Your Apiary Recovery Strategies