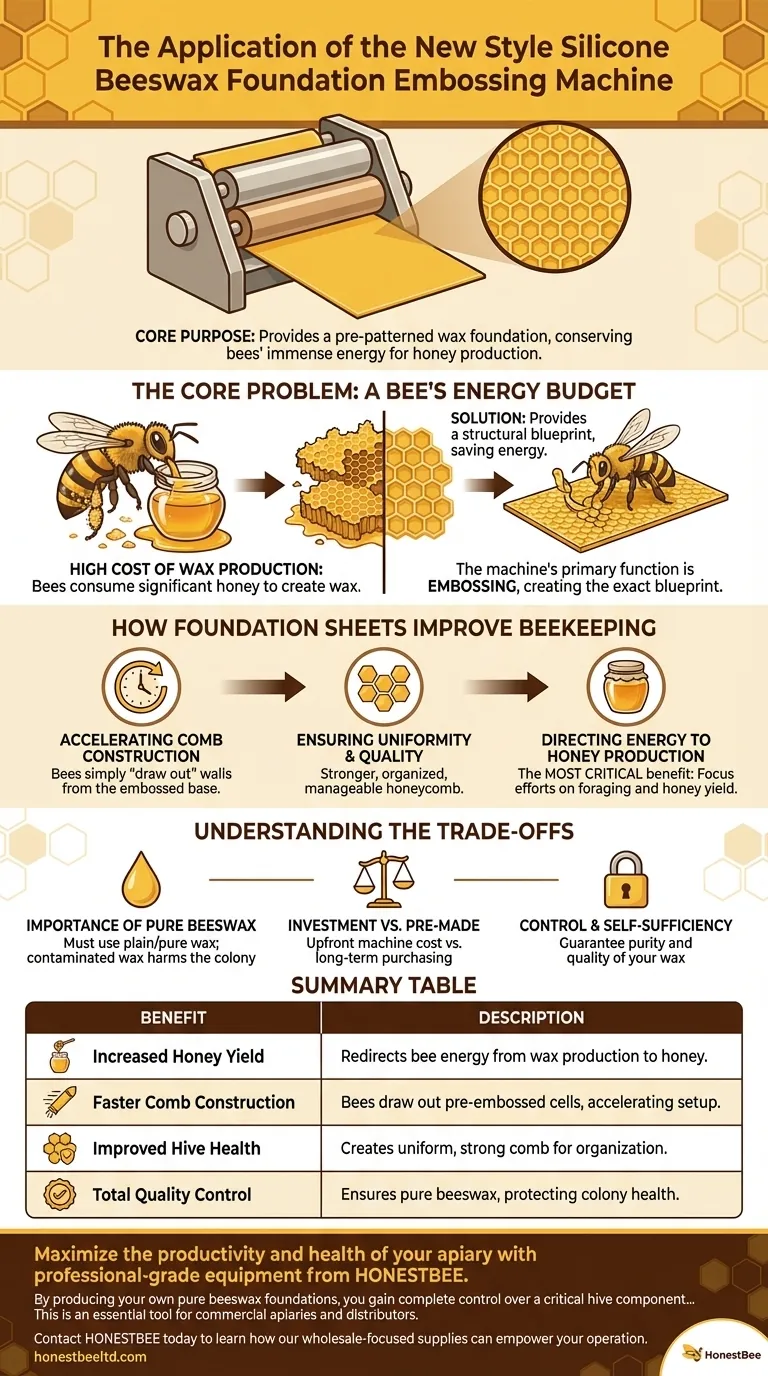

At its core, the new style Silicone beeswax foundation embossing machine is a specialized tool for beekeepers. It is used to imprint a precise hexagonal honeycomb pattern onto a plain sheet of pure beeswax, creating what is known as a beeswax foundation sheet.

The fundamental purpose of this machine is to give honeybees a head start. By providing a pre-patterned wax foundation, it conserves the bees' immense energy, redirecting their efforts from comb construction to honey production.

The Core Problem: A Bee's Energy Budget

To understand the machine's value, we must first understand the challenge a bee colony faces. Building a honeycomb from scratch is an incredibly resource-intensive task.

The High Cost of Wax Production

Bees must consume significant amounts of honey to produce tiny flakes of wax from their own bodies. They then meticulously shape this wax into the intricate hexagonal structure of their comb.

Providing a Structural Blueprint

A beeswax foundation sheet acts as a guide or a template. The embossed hexagonal pattern gives the bees the exact structure they need to begin building.

The Role of Embossing

The machine's primary function is embossing. It presses the perfect cell pattern onto a plain beeswax sheet, effectively creating the blueprint the bees will follow.

How Foundation Sheets Improve Beekeeping

By introducing these machine-made sheets into the hive, beekeepers can significantly improve the efficiency and health of their colonies.

Accelerating Comb Construction

With a foundation in place, bees don't need to build the entire structure from nothing. They simply "draw out" the walls of the cells from the embossed base, a much faster process.

Ensuring Uniformity and Quality

The machine produces foundation sheets with uniform cell sizes. This leads to a stronger, more organized, and structurally sound honeycomb, which is easier for the beekeeper to manage and inspect.

Directing Energy to Honey Production

This is the most critical benefit. By saving the bees the energy of initial comb construction, their efforts can be focused on foraging for nectar and producing honey, leading to a more productive hive.

Understanding the Trade-offs

While highly beneficial, using a foundation machine is a deliberate choice with its own set of considerations for the beekeeper.

The Importance of Pure Beeswax

The machine is designed to work with plain and pure beeswax. Using contaminated or impure wax can not only produce inferior foundation sheets but also potentially harm the health of the colony.

Investment vs. Buying Pre-Made

Owning a machine represents an upfront investment in equipment. Beekeepers must weigh this cost against the long-term benefit of producing their own sheets versus purchasing them from a supplier.

Control and Self-Sufficiency

The primary advantage for the beekeeper is control. Producing your own foundation ensures you know exactly what is going into your hives, guaranteeing the purity and quality of the wax.

Making the Right Choice for Your Apiary

Using a beeswax foundation machine is a strategic decision that aligns with specific beekeeping goals.

- If your primary focus is maximizing honey yield: This machine provides a direct path to higher production by conserving your bees' energy.

- If your primary focus is hive health and structure: Creating uniform, high-quality foundations helps promote a stronger, more organized, and healthier colony.

- If your primary focus is quality control: Producing your own foundation sheets gives you complete authority over the purity of the materials in your hives.

Ultimately, this machine empowers beekeepers to manage a fundamental aspect of the hive, turning a major energy cost for bees into a strategic advantage.

Summary Table:

| Benefit | Description |

|---|---|

| Increased Honey Yield | Redirects bee energy from wax production to foraging and honey making. |

| Faster Comb Construction | Bees draw out pre-embossed cells, accelerating hive setup. |

| Improved Hive Health | Creates uniform, strong comb for better colony organization and inspection. |

| Total Quality Control | Ensures pure beeswax foundations, protecting colony health. |

Maximize the productivity and health of your apiary with professional-grade equipment from HONESTBEE.

By producing your own pure beeswax foundations, you gain complete control over a critical hive component, leading to stronger colonies and significantly higher honey yields. This is an essential tool for commercial apiaries and distributors focused on efficiency and quality.

Contact HONESTBEE today to learn how our wholesale-focused supplies, including foundation embossing machines, can empower your beekeeping operation.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency