The ideal application for a pump filling machine is in production environments handling medium-viscosity liquids. These machines excel at moving products that are too thick for a simple gravity filler but do not require the high-power displacement of a piston filler, making them a versatile choice for larger-scale operations where consistent flow is key.

The decision between different filling technologies boils down to one critical factor: your product's viscosity. Pump filling machines are the optimal choice for products that are too thick to flow easily on their own but not viscous enough to require the heavy force of a piston system.

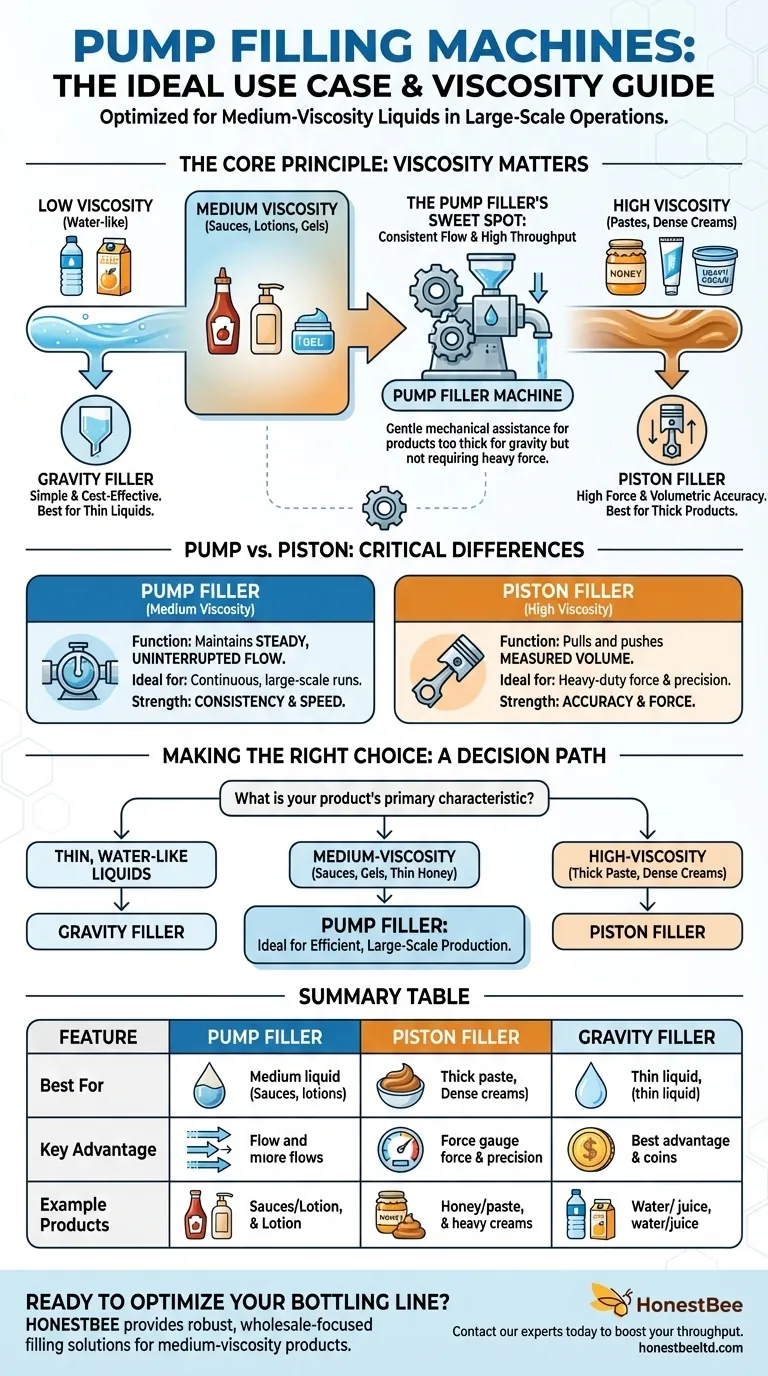

The Core Principle: Matching the Machine to the Product

Understanding Viscosity

Viscosity is simply a measure of a fluid's resistance to flow. Water has a very low viscosity, while thick honey has a very high viscosity.

This single property is the most important factor in selecting the correct filling technology for your production line.

The Pump Filler's Sweet Spot

Pump fillers are engineered for medium-viscosity liquids. This category includes products like sauces, lotions, gels, creams, and thinner honey.

These products don't flow freely with gravity alone, so they need the gentle, mechanical assistance of a pump to move them efficiently into containers.

How They Ensure Consistent Flow

The core function of a pump filler is to maintain a steady, uninterrupted flow of product from a bulk source to the filling nozzle. This makes them highly effective for continuous, larger-scale production runs where speed and consistency are primary goals.

Pump vs. Piston: The Critical Difference

Understanding the distinction between a pump filler and a piston filler is crucial for making an informed investment. The choice directly impacts your operational efficiency and product handling capability.

Pump Fillers for Consistent Flow

Pump fillers are the workhorses for moving products that are already capable of flowing, albeit slowly. They are excellent for larger batches where maintaining production speed is a priority.

Think of them as facilitators, assisting a medium-viscosity product to move faster and more consistently than it would on its own.

Piston Fillers for Heavy-Duty Force

Piston fillers are purpose-built for high-viscosity liquids like thick honey, pastes, and dense creams. They operate by pulling a specific, measured volume of product into a cylinder and then forcefully pushing it out.

This mechanism provides superior force for products that barely flow at all and also offers extremely high levels of fill accuracy and precision.

Understanding the Trade-offs

No single machine is perfect for every application. Recognizing the limitations of a pump filler is just as important as knowing its strengths.

The Upper Limit of Viscosity

The primary limitation of a pump filler is its inability to handle extremely thick, paste-like products. Attempting to run a product that is too viscous can strain the motor, lead to inconsistent fills, or cause the machine to fail entirely.

Precision vs. Throughput

While pump fillers offer excellent flow consistency, piston fillers generally provide a higher degree of volumetric accuracy for each individual fill. Pump fillers often compensate for this with higher overall throughput and speed on suitable products.

Inefficiency for Thin Liquids

For very thin, water-like liquids, a pump filler is often unnecessary. A simpler and more cost-effective gravity filler is typically the better choice for low-viscosity products.

Making the Right Choice for Your Product

To select the right machine, you must first define your product's characteristics and your primary production goal.

- If your primary focus is bottling medium-viscosity liquids like sauces, lotions, or gels: A pump filler is your ideal choice for efficient, large-scale production.

- If your primary focus is packaging high-viscosity products like thick paste or dense creams: A piston filler will provide the necessary force and volumetric accuracy you require.

- If your primary focus is bottling very thin, water-like liquids: Consider a gravity filler, as a pump system is likely unnecessary and not the most cost-effective solution.

Choosing the right equipment begins with a clear understanding of your product's fundamental properties.

Summary Table:

| Feature | Pump Filler | Piston Filler | Gravity Filler |

|---|---|---|---|

| Best For | Medium-Viscosity Liquids | High-Viscosity Pastes/Creams | Low-Viscosity, Water-like Liquids |

| Key Advantage | Consistent Flow & High Throughput | High Force & Volumetric Accuracy | Simplicity & Cost-Effectiveness |

| Example Products | Sauces, Lotions, Gels, Creams | Thick Honey, Pastes, Dense Creams | Water, Juices, Thin Oils |

Ready to optimize your bottling line for medium-viscosity products?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the robust, wholesale-focused filling solutions they need to scale production efficiently. Whether you're bottling honey, lotions, or other gels and creams, our equipment is engineered for reliable, consistent performance.

Contact our experts today to discuss how a pump filling machine can boost your throughput and profitability.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- How do automated honey filling machines ensure product quality? Enhance Standardization for Commercial Distribution

- How do industrial-grade automatic honey filling machines enhance commercial value? Scale Your Apiary Efficiency

- Why is it necessary for commercial apiaries to utilize automated honey filling machines? Scale Your Production Safely

- What advantages do industrial semi-automatic filling machines offer? Scale Your Honey Production and Consistency

- How can a honey filler be adapted for different types of containers? Master Multi-Container Filling Efficiency