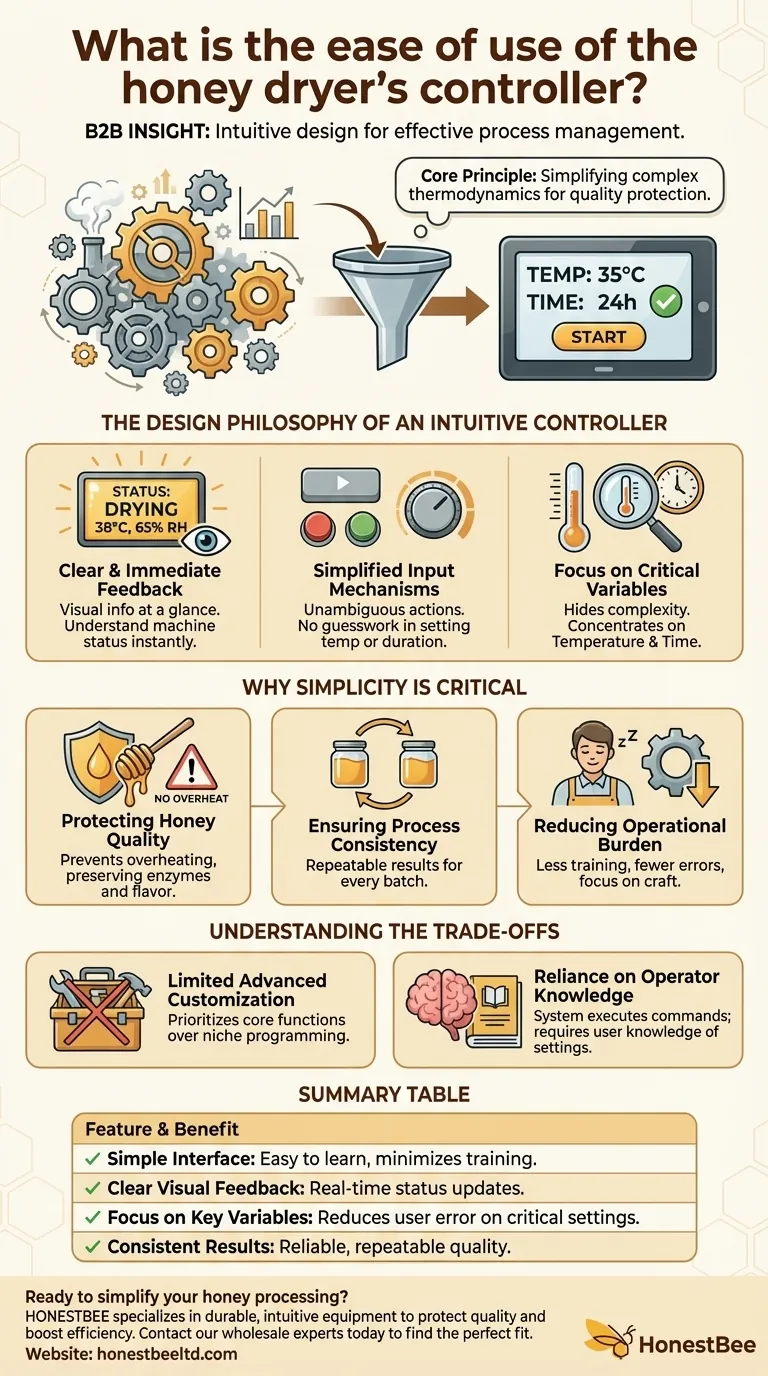

In short, the honey dryer's controller is designed to be intuitive and straightforward. Its primary goal is to allow operators to manage the honey drying process effectively without a steep learning curve or the need for specialized technical skills.

The core principle behind an easy-to-use controller is to simplify a complex thermodynamic process. It translates the precise requirements of moisture and temperature control into a simple interface, ensuring the quality of the final product is protected from user error.

The Design Philosophy of an Intuitive Controller

A well-designed controller for a honey dryer prioritizes simplicity to make the technology accessible. This focus is not just about convenience; it's about protecting the delicate properties of the honey.

Clear and Immediate Feedback

The controller provides clear visual information. This typically includes the current temperature and may involve other key metrics, allowing the operator to understand the machine's status at a glance.

Simplified Input Mechanisms

Operation is managed through simple inputs, such as buttons or dials. The goal is to make setting the desired temperature or duration an unambiguous and direct action, removing guesswork from the process.

Focus on Critical Variables

The interface deliberately hides unnecessary complexity. It focuses the user's attention on the only things that matter for a successful outcome: typically, temperature and time. This prevents the operator from making mistakes with settings that could harm the honey.

Why Controller Simplicity is Critical

The ease of use is directly tied to the final product's quality and the efficiency of your operation. An overly complex system introduces risks that can be easily avoided.

Protecting Honey Quality

Honey is sensitive to heat. Overheating can destroy its natural enzymes and degrade its unique flavor profile. An intuitive controller with precise settings prevents accidental overheating, safeguarding the value of your product.

Ensuring Process Consistency

A simple controller allows for repeatable results. Once you find the optimal settings for your honey, it's easy to replicate the process for every batch, ensuring a consistent product for your customers.

Reducing Operational Burden

Easy operation means less time spent on training and a lower chance of costly errors. This allows beekeepers and processors to focus on their craft rather than on operating complex machinery.

Understanding the Trade-offs

While simplicity is a significant advantage, it's important to understand the inherent trade-offs that come with a streamlined user interface.

Limited Advanced Customization

A controller designed for ease of use may not offer the granular, multi-stage programming that a large-scale industrial processor might require. It prioritizes core functions over advanced, niche capabilities.

Reliance on Operator Knowledge

The system is simple to operate, but it still relies on the user to know the correct temperature and duration for their specific type of honey. The controller executes commands; it does not replace the operator's fundamental knowledge.

Making the Right Choice for Your Goal

Ultimately, the controller is a tool designed to help you achieve a specific outcome.

- If your primary focus is consistency and ease of use for a small-to-medium operation: The intuitive design is ideal, as it minimizes errors and ensures reliable results without requiring technical expertise.

- If your primary focus is process efficiency and minimizing training: The straightforward operation allows any team member to manage the drying process correctly with minimal instruction.

This focus on intuitive control empowers you to master the machine quickly, letting you concentrate on what truly matters: producing high-quality honey.

Summary Table:

| Feature | Benefit |

|---|---|

| Simple Interface | Easy to learn and operate, minimizing training time. |

| Clear Visual Feedback | Real-time status updates on temperature and process. |

| Focus on Key Variables | Reduces user error by concentrating on critical settings like temperature and time. |

| Consistent Results | Ensures reliable, repeatable quality for every batch of honey. |

Ready to simplify your honey processing with reliable, easy-to-use equipment?

As HONESTBEE, we specialize in supplying durable, intuitive beekeeping supplies and equipment to commercial apiaries and distributors. Our honey dryer controllers are designed to protect your product's quality and boost your operational efficiency.

Contact our wholesale experts today to find the perfect equipment for your needs.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Professional Thermostatic Conical Honey Melter

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the drawback of the conventional honey drying method? It Compromises Honey Quality with High Heat

- What is the function of unglazed clay pots in the moisture reduction of honey? Preserving Bioactive Nutrients

- Why is a specialized honey dehydrating machine necessary for processing stingless bee honey? Prevent Spoilage Fast

- What is the function of a portable hygrometer in honey collection? Protect Your Harvest from Excess Moisture

- What are the technical benefits of using modern drying trays with a central through-hole design for bee-bread processing?

- Why must stingless bee honey undergo professional dehydration? Prevent Fermentation & Ensure Premium Product Quality

- Why is it necessary to equip honey processing workshops with industrial dehumidifiers? Prevent Spoilage and Souring

- What is the typical drying performance of the disc dehumidifier-concentrator for honey? Optimize Your Honey Processing