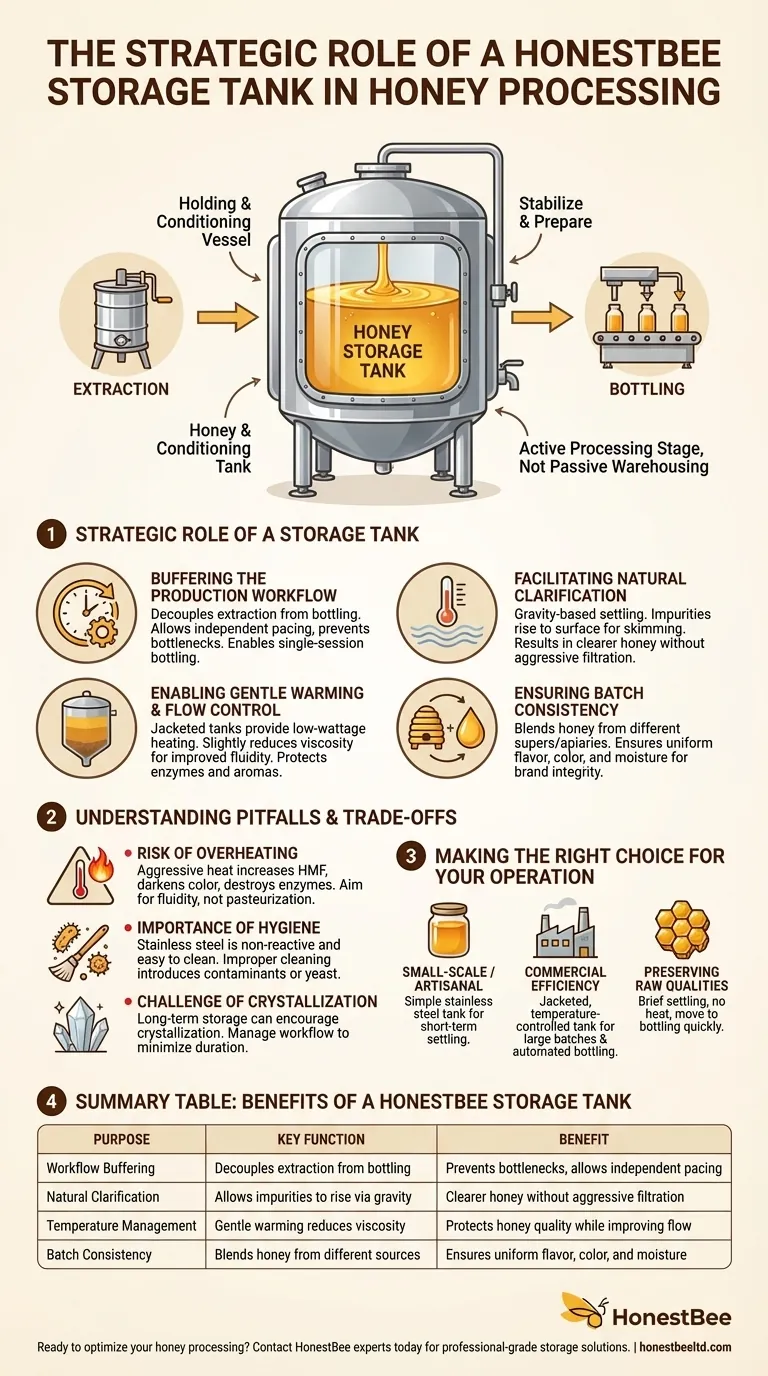

At its core, a honey storage tank serves as the critical holding and conditioning vessel between honey extraction and final bottling. While its primary purpose is to store honey, its function extends far beyond simple containment. These tanks, typically made of food-grade stainless steel, act as a crucial buffer in the production line, allowing for clarification, temperature management, and batch consistency before packaging.

A honey storage tank should not be viewed as passive warehousing, but as an active processing stage. Its true purpose is to stabilize and prepare honey, ensuring the final product maintains its quality while making the bottling process efficient and consistent.

The Strategic Role of a Storage Tank

A storage tank, often called a settling tank or holding tank, is a central hub in a well-managed honey processing operation. Its role is multifaceted, directly impacting both product quality and workflow efficiency.

Buffering the Production Workflow

A storage tank decouples the extraction process from the bottling process. You can extract honey for days and accumulate it in the tank, then run your bottling line efficiently in a single, dedicated session.

This buffer prevents bottlenecks and allows each stage of the operation to proceed at an optimal, independent pace.

Facilitating Natural Clarification

When raw honey is held undisturbed in a tank, its natural density allows for gravity-based clarification. Lighter impurities, such as fine wax particles and air bubbles introduced during extraction, will slowly rise to the surface.

This process, known as settling, allows you to skim these impurities off the top, resulting in a clearer, more visually appealing final product without aggressive filtration.

Enabling Gentle Warming and Flow Control

Honey is viscous, and its flow rate is highly dependent on temperature. Many storage tanks are "jacketed" or equipped with low-wattage heating elements.

The goal is not to "cook" the honey, but to warm it gently. This slightly reduces its viscosity, making it flow easily through pumps and into bottling equipment without causing damage to the honey's delicate enzymes and aromas. This improves what the references call "fluidity."

Ensuring Batch Consistency

For larger operations, a single large tank allows you to blend honey from different supers or apiaries. This helps create a final product with a consistent flavor, color, and moisture content, which is critical for brand integrity.

Understanding the Pitfalls and Trade-offs

Using a storage tank correctly is key to preserving honey quality. Mismanagement at this stage can easily degrade the final product.

The Risk of Overheating

The single greatest risk is applying too much heat. Aggressive or uneven heating can destroy beneficial enzymes, increase HMF (hydroxymethylfurfural) levels, and darken the honey's color, compromising its quality as a raw product.

Temperature control must be precise and gentle, aiming only to improve fluidity, not to pasteurize.

The Importance of Hygiene

Honey is acidic and hygroscopic (it absorbs moisture), making the choice of tank material critical. Stainless steel is the industry standard because it is non-reactive and easy to clean and sanitize.

Improperly cleaned tanks can introduce contaminants or fermentation yeasts, spoiling presentazione an entire batch of honey.

The Challenge of Crystallization

Storing honey for extended periods, especially at cooler temperatures, can encourage crystallization. While gentle warming in the tank can help re-liquefy crystals, it is best to manage your workflow to minimize long-term storage.

Making the Right Choice for Your Operation

The ideal storage tank setup depends entirely on the scale and goals of your honey operation.

- If your primary focus is small-scale, artisanal production: A simple stainless steel tank used for short-term settling and clarification is often sufficient.

- If your primary focus is commercial efficiency and volume: A jacketed, temperature-controlled tank is essential for maintaining a consistent workflow and preparing large batches for automated bottling.

- If your primary focus is preserving raw honey qualities: Use the tank primarily for brief settling periods with no heat application, moving the honey to bottling as quickly as possible.

Ultimately, the right storage tank transforms honey processing from a series of disjointed tasks into a streamlined, quality-focused system.

Summary Table:

| Purpose | Key Function | Benefit |

|---|---|---|

| Workflow Buffering | Decouples extraction from bottling | Prevents bottlenecks, allows independent pacing |

| Natural Clarification | Allows impurities to rise via gravity | Clearer honey without aggressive filtration |

| Temperature Management | Gentle warming reduces viscosity | Protects honey quality while improving flow |

| Batch Consistency | Blends honey from different sources | Ensures uniform flavor, color, and moisture |

Ready to optimize your honey processing with the right equipment?

For commercial apiaries and beekeeping equipment distributors, the correct storage tank is the cornerstone of an efficient, high-quality operation. HONESTBEE supplies professional-grade, food-grade stainless steel honey storage tanks and a full range of beekeeping supplies through our wholesale-focused operations.

We help you protect your honey's quality while streamlining your workflow for maximum output. Contact our experts today to discuss the ideal storage solution for your scale and goals.

Visual Guide

Related Products

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Heated Honey Tank Warming Heating Tank

People Also Ask

- What is the role of industrial weighing instruments in honey processing? Ensure Compliance and Yield Management

- How do the facilities within a honey processing plant influence market positioning? Unlock Premium Global Value

- How does a constant temperature water bath ensure reliable results during the measurement of honey diastase activity?

- How does an industrial-grade muffle furnace operate for honey ash determination? Ensure Precise Mineral Analysis

- How is a colorimeter used to evaluate the color grade of honey? Standardize Quality with Pfund Grading

- What is an efficient method for processing honey when dealing with dozens of hives? Scale Up Your Apiary's Harvest

- How does honey processing equipment contribute to the quality of honey? Boost Your Marketability and Retail Value

- How does natural beekeeping affect honey machinery requirements? Adapt Your Equipment for High-Value Organic Success