At its core, a wax melting pot is a specialized container used in beekeeping to heat and liquefy beeswax from old or used honeycombs. By raising the temperature above +70°C (158°F), it separates the pure wax from hive debris, allowing the beekeeper to reclaim this valuable resource for future use.

The function of a wax melting pot goes beyond simply melting wax. It is the primary tool for a critical beekeeping practice: recycling beeswax. This process turns a waste product—old combs—into a foundational asset for promoting hive health, productivity, and apiary self-sufficiency.

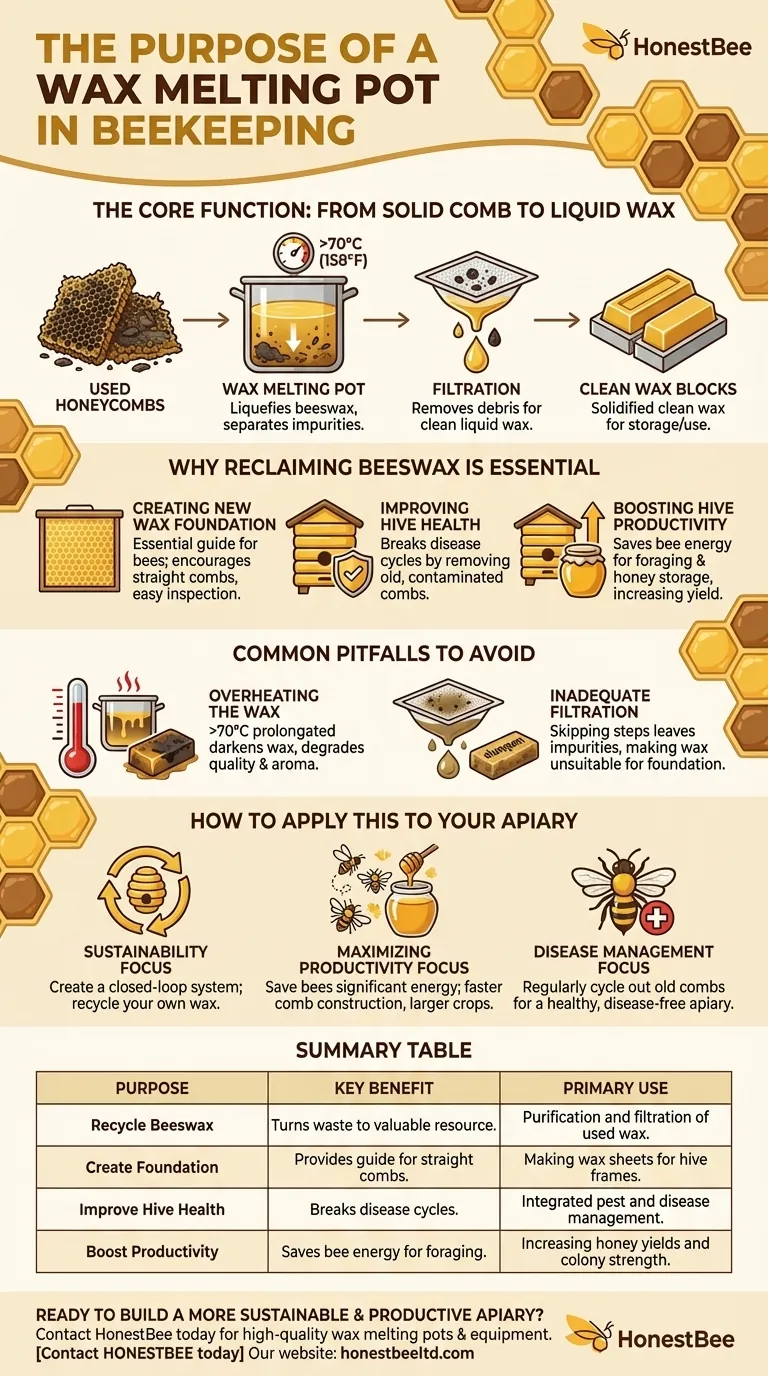

The Core Function: From Solid Comb to Liquid Wax

A wax melting pot is the first step in the wax rendering process. It takes used, dark, or damaged combs and begins the process of purification.

The Melting Process

Beeswax has a melting point of around 62-64°C, but rendering is most effective at slightly higher temperatures. The melting pot heats the old combs to over 70°C, ensuring the wax liquefies completely.

This process allows the liquid wax to separate from heavier debris, such as bee cocoons, pollen, and other hive residue, which tend to sink.

The Need for Filtration

Once melted, the liquid wax is poured through a filter or straining cloth. This step removes any remaining solid impurities, resulting in clean, liquid beeswax.

This filtered wax is then typically poured into molds to cool and solidify into clean, manageable blocks for storage or immediate use.

Why Reclaiming Beeswax is Essential

Melting wax isn't just about cleaning up; it's a strategic activity that underpins modern, efficient beekeeping by creating a vital material for the apiary.

Creating New Wax Foundation

The single most important use for rendered beeswax is creating wax foundation. These are thin sheets of beeswax embossed with the hexagonal pattern of honeycomb cells.

When placed in a hive, this foundation provides a guide for the bees. It encourages them to build straight, uniform combs, which are essential for easy hive inspection and honey extraction.

Improving Hive Health

Old combs can harbor pathogens and residues from treatments. Regularly rotating out old combs and replacing them with fresh foundation made from clean, rendered wax helps break potential disease cycles.

This practice is a key component of integrated pest and disease management in a modern apiary.

Boosting Hive Productivity

Building wax comb from scratch requires a tremendous amount of energy from the bees. Providing them with a wax foundation gives them a significant head start.

This allows the colony to redirect its energy from wax production to other vital tasks, such as foraging, raising brood, and storing honey, thereby increasing the hive's overall productivity.

Common Pitfalls to Avoid

While the process is straightforward, quality control is crucial. How you melt the wax directly impacts the quality of the final product.

Overheating the Wax

Exceeding the necessary temperature for prolonged periods can darken the beeswax and degrade its quality and aroma. Careful temperature control is key to producing a light-colored, high-quality wax block.

Inadequate Filtration

Skipping or rushing the filtration step will result in a final wax block that contains impurities. This "slumgum" can make the wax unsuitable for creating foundation and reduces its overall value.

How to Apply This to Your Apiary

Using a wax melting pot supports several key beekeeping goals. Your primary objective will determine how you prioritize this activity.

- If your primary focus is sustainability: A melting pot allows you to create a closed-loop system, recycling your own wax instead of purchasing it.

- If your primary focus is maximizing productivity: Providing bees with foundation made from recycled wax saves them significant energy, leading to faster comb construction and larger honey crops.

- If your primary focus is disease management: Regularly cycling out old combs and rendering them down is a critical step in maintaining a healthy, disease-free apiary.

Mastering the wax rendering process transforms the beekeeper from a honey harvester into a manager of the hive's complete resource cycle.

Summary Table:

| Purpose | Key Benefit | Primary Use |

|---|---|---|

| Recycle Beeswax | Turns old comb from waste into a valuable resource. | Purification and filtration of used wax. |

| Create Foundation | Provides a guide for bees to build straight, uniform combs. | Making wax sheets for hive frames. |

| Improve Hive Health | Breaks disease cycles by removing old, contaminated combs. | Integrated pest and disease management. |

| Boost Productivity | Saves bees energy, allowing focus on foraging and honey storage. | Increasing honey yields and colony strength. |

Ready to build a more sustainable and productive apiary?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, durable wax melting pots and other essential tools needed to efficiently manage your wax resources. By reclaiming your own beeswax, you can reduce costs, improve hive health, and maximize honey production.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can support your beekeeping success.

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What are the functions of wire-tensioning tools and wax foundation installation equipment in frame pretreatment?

- What is the final step in wiring a frame? Secure Lasting Tension for a Durable Hive

- What is the primary function of an electric embedder? Secure Your Beeswax Foundation with Heat Fusion

- What methods are used to embed wire into the foundation? A Guide to Stronger, More Durable Beehives

- How does the frame wiring jig assist in running horizontal wires through frames? Streamline Your Beekeeping Setup