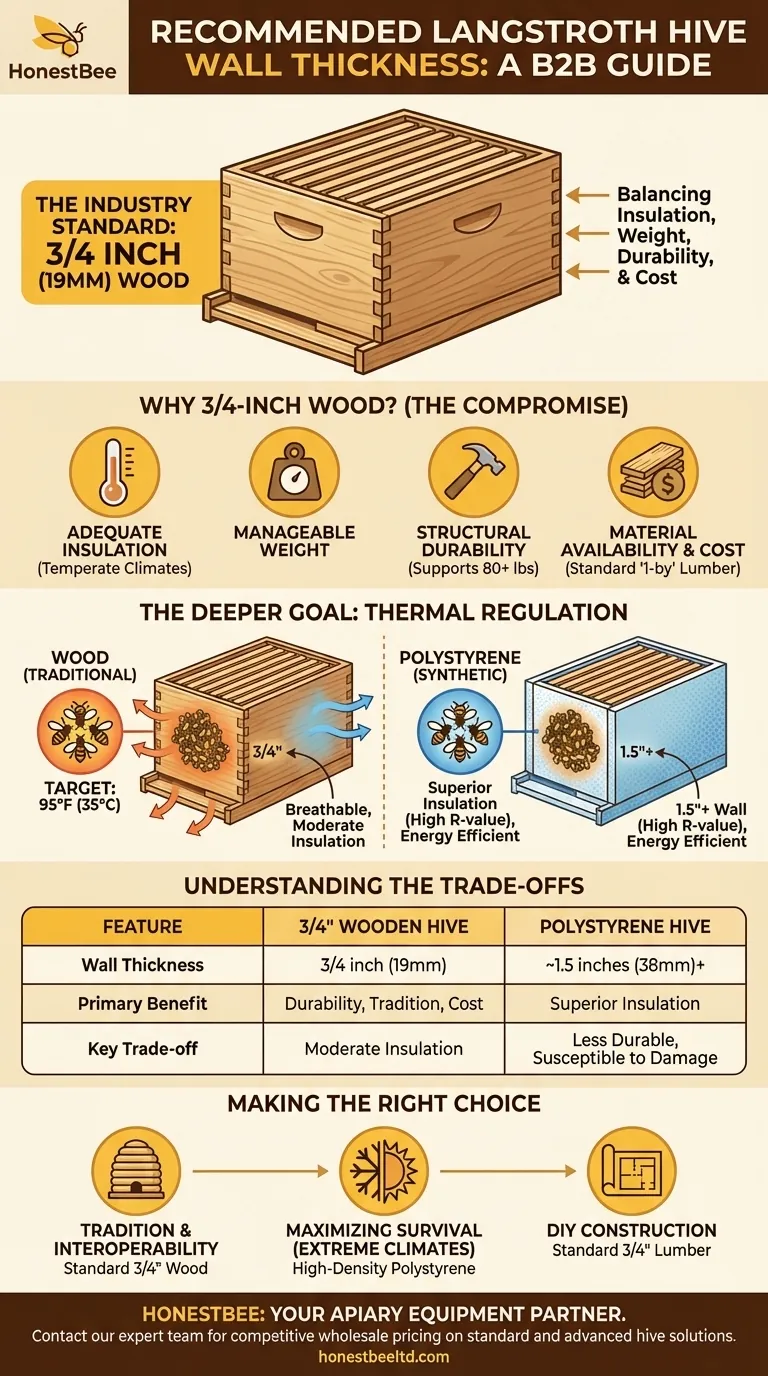

For a standard wooden Langstroth hive, the commonly recommended and widely used wall thickness is 3/4 of an inch (19mm). While this is not a mandatory standard, it has become the industry default for hives made from woods like pine or cedar. Hive bodies constructed from synthetic materials like high-density polystyrene will be significantly thicker to leverage their insulating properties.

The 3/4-inch measurement for wooden hives is a long-standing compromise between providing adequate insulation, ensuring structural durability, and managing material cost and weight. The choice of material, however, has a far greater impact on the hive's thermal performance than minor variations in thickness.

Why 3/4-Inch is the Standard for Wood

The widespread adoption of 3/4-inch walls for wooden hives is not accidental. It is the result of balancing several practical factors that affect both the bees and the beekeeper.

A Balance of Insulation and Weight

A 3/4-inch solid wood wall provides a baseline level of insulation that is sufficient for honey bee colonies in most temperate climates. It helps buffer the interior from daily temperature swings without making the hive boxes excessively heavy and difficult to lift.

Structural Durability

Hive bodies must withstand significant stress. A deep hive box full of honey can weigh over 80 pounds (36 kg), and the walls need to support this load without warping or breaking, especially during inspections and transport. A 3/4-inch thickness provides this necessary rigidity.

Material Availability and Cost

Standard dimensional lumber is readily available and cost-effective in this thickness (often sold as "1-by" or 1x material, which has an actual thickness of 3/4"). This makes it an economical and practical choice for both commercial manufacturers and DIY beekeepers.

The Deeper Goal: Thermal Regulation

The primary function of the hive wall is to help the colony maintain a stable internal temperature. The bee cluster works to keep the central brood area at a constant 95°F (35°C), and effective walls reduce the energy (and honey) they must expend to do so.

Wood as the Traditional Choice

Wood is a decent insulator that also has the benefit of "breathing," allowing some moisture to pass through the walls. This can help reduce condensation inside the hive, which is a major threat to a colony during winter. The 3/4-inch standard is the accepted baseline for this material.

Synthetic Hives (Polystyrene)

Modern high-density polystyrene hives are designed specifically for superior insulation. Their walls are often 1.5 inches (38mm) or thicker, providing an insulation value (R-value) many times higher than wood. This dramatically improves overwintering survival rates in cold climates and keeps the hive cooler in extreme heat.

Understanding the Trade-offs

Choosing a wall thickness or material involves accepting a set of compromises. Understanding these is key to making an informed decision for your specific needs.

Thinner Walls (< 3/4")

Going thinner than the 3/4-inch standard will make the boxes lighter and cheaper but at a significant cost to the bees. Poor insulation means the colony must consume more winter stores to generate heat and may struggle to keep the brood nest cool in the summer.

Thicker Walls (> 3/4")

Using thicker wood, such as 1.5-inch lumber, will noticeably improve insulation. However, this makes the equipment much heavier, more expensive, and can create compatibility issues, as the hive's external dimensions will no longer be standard.

The Material Question: Wood vs. Polystyrene

The central trade-off is often not about thickness but material. Wood is durable, traditional, and breathable but offers moderate insulation. Polystyrene provides exceptional insulation but is more susceptible to physical damage from pests or mishandling and is not a natural material.

Making the Right Choice for Your Goal

Your local climate and beekeeping philosophy should guide your decision.

- If your primary focus is tradition and interoperability: Standard 3/4-inch pine or cedar equipment is the universal and most reliable choice.

- If your primary focus is maximizing bee survival in very cold winters or hot summers: A high-density polystyrene hive is objectively superior for its thermal performance.

- If your primary focus is DIY construction: Sticking to plans based on standard 3/4-inch lumber will be the most straightforward and cost-effective approach.

Ultimately, selecting the right hive body is about providing a stable environment that allows your bees to thrive with the least amount of stress.

Summary Table:

| Feature | 3/4" Wooden Hive | Polystyrene Hive |

|---|---|---|

| Wall Thickness | 3/4 inch (19mm) | ~1.5 inches (38mm) or more |

| Primary Benefit | Durability, cost-effectiveness, tradition | Superior insulation (high R-value) |

| Best For | Most temperate climates, standard equipment | Extreme cold or hot climates |

| Key Trade-off | Moderate insulation | Less durable, susceptible to damage |

Equip your apiary with the right foundation for success. Whether you manage a few hives or a large commercial operation, the right equipment is critical for colony health and honey production. HONESTBEE supplies durable, high-quality beekeeping supplies and equipment—including standard wooden hive bodies and advanced polystyrene options—to commercial apiaries and distributors through our wholesale-focused operations. Let's discuss the best hive solutions for your specific climate and goals. Contact our expert team today for competitive pricing and reliable supply.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Solid Bottom Board Australian Pine Wood Langstroth Bottom Board for Wholesale

People Also Ask

- Why is the use of newly manufactured 10-frame hive bodies recommended for colony health and medication assessment?

- Which Langstroth box configurations are recommended for beekeepers seeking to reduce lifting weight? Ergonomic Solutions

- What is the role of Movable Frame Hives in the context of intensive and standardized beekeeping? Scale Your Yield 3x

- Why might a beginner be advised to start with a Langstroth hive? Unlock a Supportive Beekeeping Ecosystem

- Why were wooden hives traditionally preferred? For Natural Beekeeping Aligned with Bee Biology