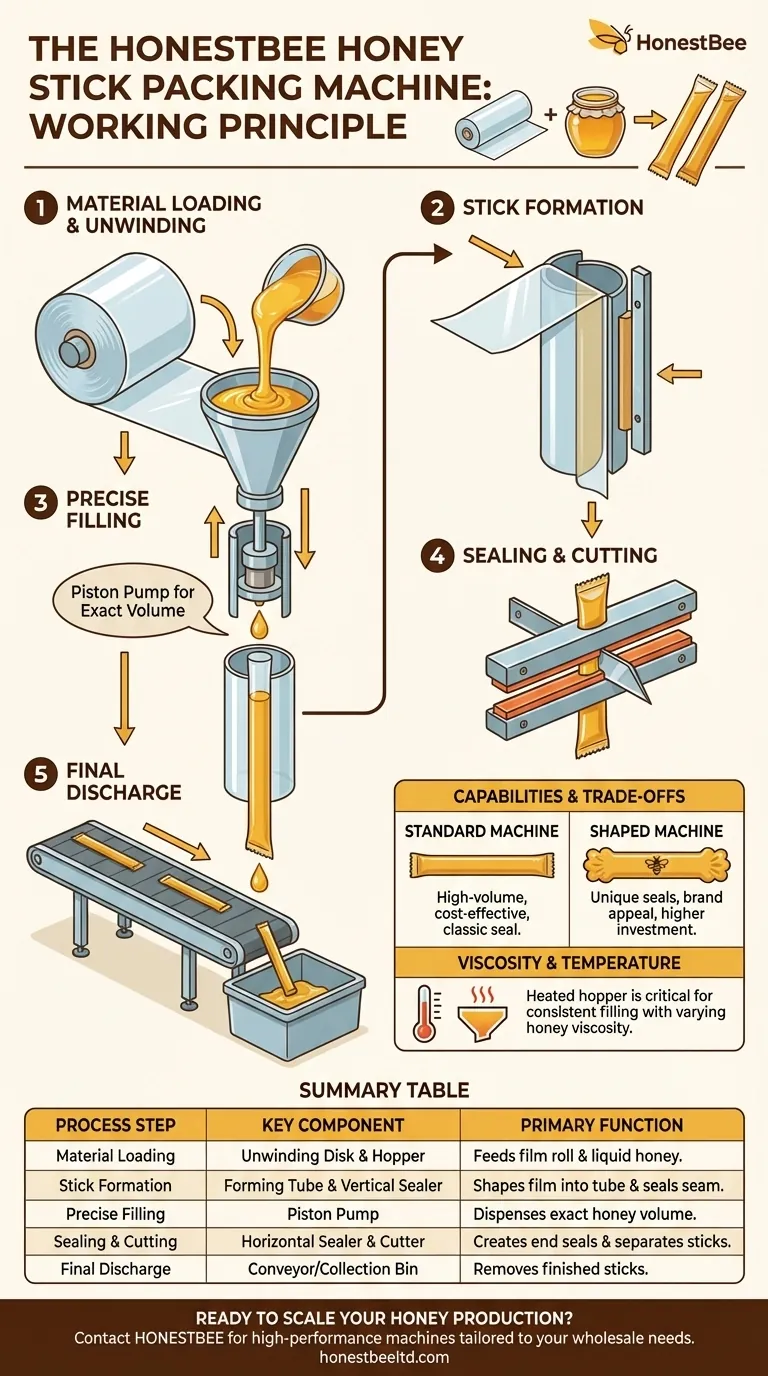

At its core, a honey stick packing machine is a fully automated system that transforms two raw materials—a flat roll of packaging film and liquid honey—into sealed, single-serving sticks. The machine systematically forms the film into a tube, uses a high-precision pump to fill it with a measured amount of honey, and then seals and cuts the individual sticks in a continuous, synchronized process.

The working principle is not a single action but a sequential, automated assembly line contained within one machine. It relies on the precise coordination of mechanical components to form, fill, seal, and cut the packaging film at a high speed.

The Automated Journey: From Film Roll to Finished Stick

To understand the machine, it's best to follow the path of the materials from start to finish. Each step is handled by a specific set of components working in concert.

Step 1: Material Loading and Unwinding

The process begins with loading the raw materials. A large roll of packaging film is mounted on an unwinding disk, and liquid honey is poured into a dedicated hopper.

The film is then fed from the roll into the machine, passing over a series of rollers that maintain proper tension.

Step 2: Stick Formation

The flat film is guided toward a forming tube. As the film wraps around this tube, it is shaped from a flat sheet into a long, continuous cylinder.

A vertical sealing bar then presses against the overlapping edges of the film, using heat to create the long back seam you see on a finished honey stick.

Step 3: Precise Filling

Once the tube is formed and sealed vertically, the filling station takes over. A piston pump, connected to the honey hopper, dispenses a precise, pre-measured volume of honey down through the forming tube into the sealed film.

This mechanism is critical for ensuring every stick contains the exact same amount of product, maintaining consistency and controlling costs.

Step 4: Sealing and Cutting

With the honey inside, a horizontal sealing bar clamps down on the tube. This action performs two jobs at once: it creates the top seal for the stick that was just filled and the bottom seal for the next stick to be filled.

Immediately after sealing, a sharp cutter, often integrated with the horizontal sealer, slices through the seal to separate the finished honey stick from the continuous tube.

Step 5: Final Discharge

The completed, individual honey stick is now discharged from the machine, typically onto a conveyor belt or into a collection bin, ready for secondary packaging.

Understanding the Capabilities and Trade-offs

While the core principle is the same, not all machines are created equal. Understanding the key differences is crucial for making an informed investment.

Standard vs. Shaped Machines

A standard machine produces the classic, straight-edged honey stick efficiently and is the most common type.

A shaped machine uses custom sealing jaws to create unique, stylized seals on the ends of the sticks. While this enhances marketability and can attract different customers (like children), these machines represent a higher initial investment.

The Critical Role of Viscosity

The performance of the piston pump is directly affected by the honey's viscosity, which changes with temperature. Thicker, colder honey is harder to pump accurately.

For consistent filling, many operations require a heated or jacketed hopper to keep the honey at an optimal, uniform temperature, ensuring each stick is filled correctly.

Customization and Output

Beyond shape, machines can be customized to produce sticks of different lengths and widths. The sealing bars can also be changed to create different patterns, such as standard flat seals or embossed logos. These factors, along with the machine's motor and control system, determine the final output speed, measured in sticks per minute.

Making the Right Choice for Your Operation

Understanding the working principle allows you to select a machine that aligns perfectly with your business goals.

- If your primary focus is high-volume, cost-effective production: A standard machine with a reliable, heated hopper and a high-speed piston pump is your most efficient choice.

- If your primary focus is brand differentiation and market appeal: A shaped honey stick machine provides unique sealing options that can make your product stand out, justifying the higher initial investment.

- If your primary focus is operational flexibility: Prioritize a machine with easily adjustable parameters for stick length, fill volume, and interchangeable forming tubes to handle different product runs.

By matching the machine’s mechanics to your production needs, you can ensure a reliable and profitable operation.

Summary Table:

| Process Step | Key Component | Primary Function |

|---|---|---|

| Material Loading | Unwinding Disk & Hopper | Feeds film roll and liquid honey into the machine. |

| Stick Formation | Forming Tube & Vertical Sealer | Shapes flat film into a tube and seals the long seam. |

| Precise Filling | Piston Pump | Dispenses an exact volume of honey into the film tube. |

| Sealing & Cutting | Horizontal Sealer & Cutter | Creates end seals and cuts the tube into individual sticks. |

| Final Discharge | Conveyor/Collection Bin | Removes finished sticks for secondary packaging. |

Ready to scale your honey production with precision and reliability?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance honey stick packing machines tailored for wholesale operations. Whether you need a high-volume standard machine or a branded shaped machine, our equipment ensures consistent, accurate filling and sealing to maximize your profitability.

Contact our experts today to discuss the perfect machine for your operation's specific goals and volume requirements.

Visual Guide

Related Products

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- Which factors determine the operational efficiency of professional honey-filling machines? Boost Your Production Flow

- What are the benefits of using an automatic honey filling machine? Boost Your Apiary's Efficiency & Profitability

- What is the recommended temperature for honey during the straw-filling process? Optimize Your Honey Flow & Quality

- Why is the use of high-precision automatic filling and sealing machines critical in propolis aerosol production?

- What role do honey filling machines play in meeting quality standards? Ensure Global Export Compliance

- Why are high-precision honey filling machines critical? Enhance Your Competitiveness and Product Consistency

- What are the advantages of honey sachet packing machines? Boost Efficiency & Unlock New Markets

- How do industrial-grade honey filling machines contribute to cost reduction? Boost Efficiency and Profit Margins