At its core, the versatility of a honey heating tank stems from its ability to adapt to different types of honey and varying operational scales. These tanks are engineered to handle everything from raw, unfiltered honey to fully crystallized or creamed honey, with models offering adjustable configurations to match any batch size, from a hobbyist’s bucket to a commercial drum.

A truly versatile honey tank is more than a heater; it is a strategic asset. Its value lies in its capacity to adapt to your honey's physical state, your current production volume, and your future business growth, ensuring product quality and operational efficiency at every step.

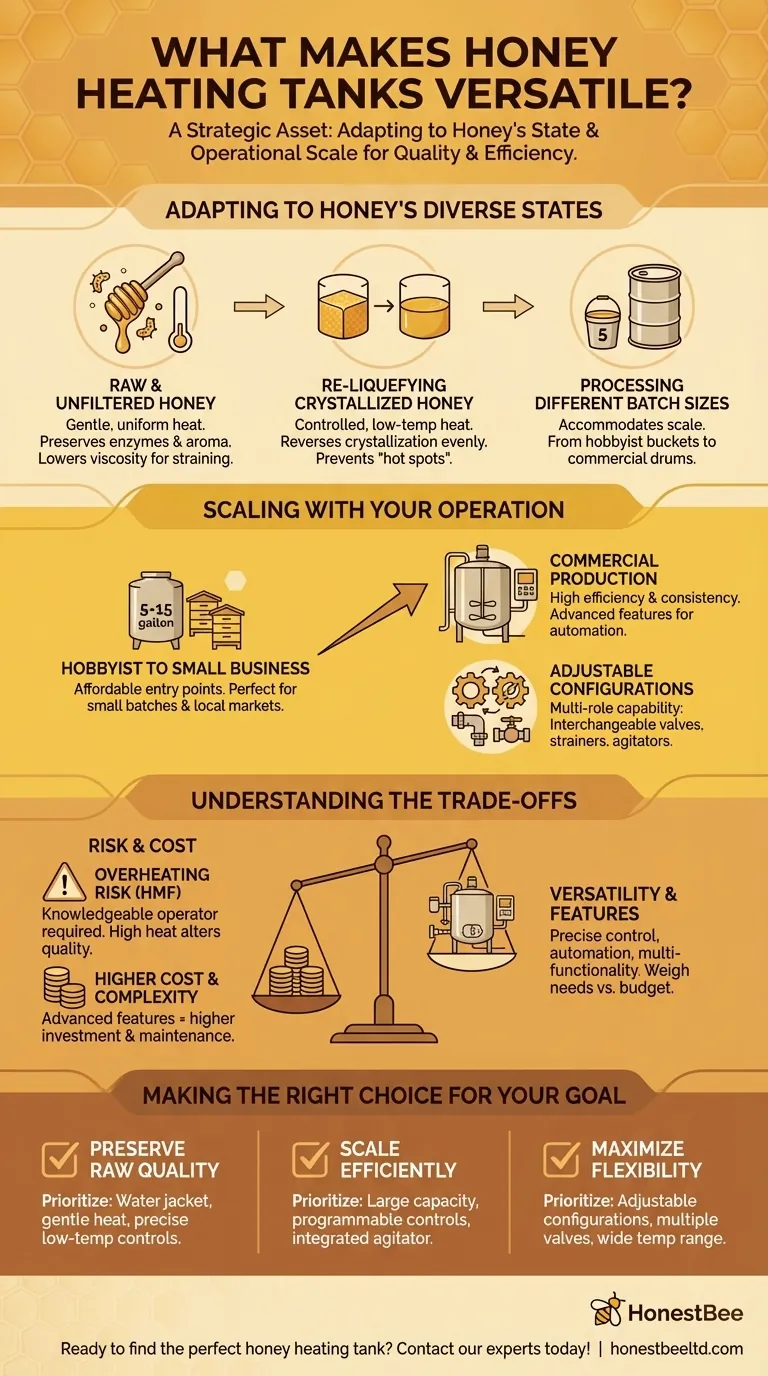

Adapting to Honey's Diverse States

Honey is not a uniform product. Its viscosity, crystallization state, and composition demand different handling protocols. A versatile tank provides the precise control needed to manage these variations without compromising quality.

Handling Raw and Unfiltered Honey

Raw honey contains beneficial enzymes and delicate aromatic compounds that are easily destroyed by excessive heat. A quality heating tank, often using a water jacket, applies gentle, uniform heat. This lowers the honey's viscosity just enough for straining and bottling while preserving its natural, valuable properties.

Re-liquefying Crystallized Honey

Crystallization is a natural process, but it renders honey solid and unsellable in a liquid state. A heating tank is the professional's tool for gently and evenly reversing this process. By applying controlled, low-temperature heat over time, it can return a large batch to a liquid state without creating "hot spots" that would caramelize and ruin the product.

Processing Different Batch Sizes

Versatility also means accommodating scale. Beekeepers and producers handle vastly different volumes. Heating tanks are designed to meet these needs, from small-capacity units ideal for a few hives to massive commercial tanks that can process thousands of pounds.

Scaling with Your Operation

As a beekeeping operation grows, its processing needs change dramatically. The right equipment can grow with you, preventing the need for frequent and costly replacements.

From Hobbyist to Small Business

For those starting out, smaller tanks (e.g., 5-15 gallons) offer an affordable entry point. These units are perfect for liquefying crystallized honey from a few hives and preparing small batches for local markets. They provide the fundamental control needed to produce a professional-quality product.

For Commercial Production

Large-scale operators require efficiency and consistency. Commercial tanks are built for this, with capacities of hundreds of gallons. They often include advanced features like integrated agitators to ensure even heating and programmable temperature controls to automate the process for different honey types, ensuring every batch meets the same standard.

The Role of Adjustable Configurations

The most versatile models offer configurations that can be changed to suit the task. This might include interchangeable outlet valves for different container sizes, removable strainers for filtering, or the ability to add a motor for automated stirring. This adaptability allows one tank to perform multiple roles in the production line.

Understanding the Trade-offs

While versatility is a key benefit, it's crucial to understand the associated responsibilities and limitations.

The Risk of Overheating

The primary function of a heating tank is also its biggest risk. A versatile tank with a wide temperature range requires a knowledgeable operator. Setting the temperature too high can rapidly increase HMF (Hydroxymethylfurfural) levels, destroying the honey's natural enzymes and fundamentally altering its quality.

Cost vs. Features

Greater versatility comes at a price. A simple, single-purpose liquefier is far less expensive than a multi-function, water-jacketed tank with programmable controls and an agitator. You must weigh the need for advanced features against your budget and production goals.

Maintenance and Complexity

Tanks with more features, such as integrated pumps, agitators, and complex valve systems, naturally require more diligent cleaning and maintenance. A simple bucket-style heater is easier to manage than a large, automated commercial unit.

Making the Right Choice for Your Goal

Selecting the right tank requires aligning its capabilities with your specific operational needs.

- If your primary focus is preserving raw honey quality: Prioritize a tank with a water jacket for gentle, even heating and precise low-temperature controls.

- If your primary focus is scaling production efficiently: Look for a tank with a large capacity and features that support automation, such as programmable controls and an integrated agitator.

- If your primary focus is maximum product flexibility: Choose a model with adjustable configurations, multiple gate valve options, and a wide, controllable temperature range to handle liquefying, creaming, and bottling.

Ultimately, choosing the right honey heating tank empowers you to control your process and consistently deliver a high-quality product, no matter your scale.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Gentle, Water-Jacket Heating | Preserves raw honey's enzymes & aroma | Raw honey producers |

| Controlled Re-liquefaction | Safely melts crystallized honey without hot spots | Beekeepers with crystallized stocks |

| Scalable Capacity (5-1000+ gal) | Grows with your operation, from hobbyist to commercial | Operations planning for growth |

| Adjustable Configurations | Adapts valves, strainers, and agitators for different tasks | Producers needing multi-function equipment |

Ready to find the perfect honey heating tank for your operation?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the precise, scalable heating tanks they need to ensure product quality and operational efficiency. Whether you're processing raw honey, re-liquefying large batches, or scaling up production, our wholesale-focused operations provide the right equipment for your goals.

Contact our experts today to discuss your specific needs and discover how our versatile heating tanks can become a strategic asset for your business.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Professional Honey Filter with Tripod Support Stand

People Also Ask

- Why is industrial-grade constant temperature heating equipment essential for the detoxification processing of specialty honey? Ensure Consumer Safety

- What is the purpose of the double-walled stainless steel tank in the honey mixer? Gentle, Even Heat for Quality Honey

- How do honey heating tanks ensure hygiene and sanitation? A Guide to Food-Grade Design

- What is the primary role of a honey heating tank? Enhance Your Honey Processing Flow and Quality

- What design features contribute to the energy efficiency of modern honey heating tanks? Maximize Your Apiary's Savings