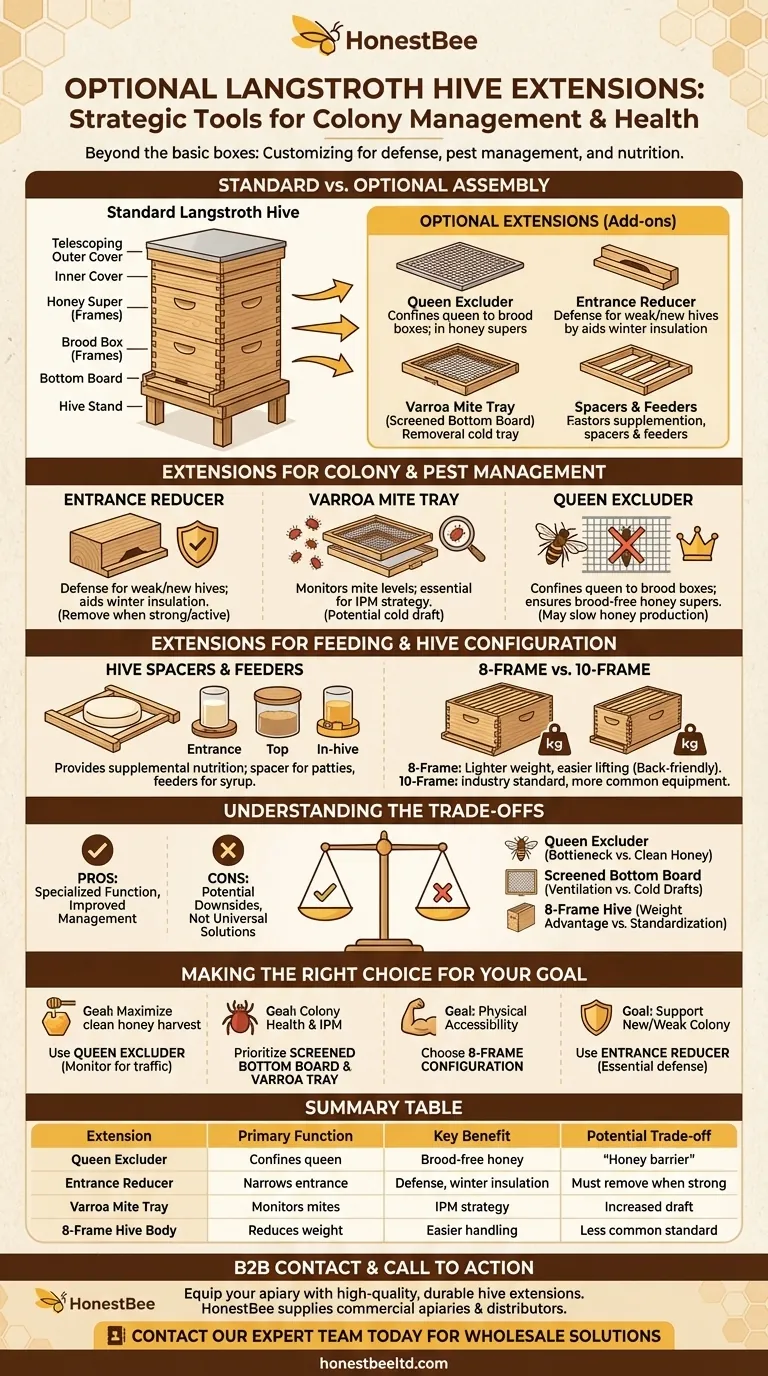

Beyond the basic boxes and frames, a Langstroth hive can be customized with several optional extensions designed to manage the colony and improve hive health. The most common optional components include queen excluders to control laying patterns, entrance reducers for defense, varroa mite inspection trays for pest management, and spacers or dedicated feeders for providing supplemental nutrition.

While a standard hive is perfectly functional, optional extensions are not mere accessories but strategic tools. Each component serves a specific purpose—from pest management to honey production control—and understanding their function is the key to proactive and effective beekeeping.

Differentiating Standard vs. Optional Components

To understand what is optional, we must first define what is standard. A functional hive requires a core set of parts, while extensions add specialized capabilities.

The Standard Langstroth Assembly

A basic, operational Langstroth hive consists of a bottom board, one or more hive boxes (supers) containing frames, an inner cover, and a telescoping outer cover for weather protection.

It is also a universal best practice to place the entire hive on a hive stand to improve ventilation and protect it from ground moisture and pests.

The Role of Optional Extensions

Optional extensions are specialized pieces of equipment you add to this standard setup. They are deployed to solve specific problems, achieve particular goals, or adapt the hive to seasonal conditions.

Extensions for Colony and Pest Management

These components are primarily focused on defending the colony from outside threats and managing internal pests, especially the Varroa destructor mite.

The Entrance Reducer

An entrance reducer is a small block of wood that narrows the main hive entrance on the bottom board.

Its purpose is to give the colony a smaller, more defensible opening. This is critical for new or weak hives that are vulnerable to being robbed of their honey by stronger nearby colonies. It also aids in temperature regulation during winter.

The Varroa Mite Tray (Screened Bottom Board)

This extension is typically a screened bottom board that replaces the standard solid one, with a removable tray underneath.

Its primary function is to help you monitor Varroa mite levels. As mites fall off the bees, they pass through the screen and land on the sticky board or tray, where they can be counted. This data is essential for making informed decisions about mite treatments as part of an Integrated Pest Management (IPM) strategy.

The Queen Excluder

This is a flat grid of wires or plastic placed between the brood boxes (where the queen lays eggs) and the honey supers above.

The slots are large enough for worker bees to pass through but too small for the larger queen. This confines the queen to the lower boxes, ensuring the honey supers contain only honey and are free of eggs, larvae, and pupae, which simplifies the harvesting process.

Extensions for Feeding and Hive Configuration

These options relate to providing food for the colony and making fundamental choices about the hive's size and weight.

Hive Spacers and Feeders

The simplest option is a "spacer," a wooden rim that adds a small amount of space to a hive box. This space can be used to place a winter sugar patty or pollen patty directly on top of the frames.

More broadly, various types of feeders are available to provide sugar syrup when natural nectar is scarce. These include entrance feeders, top feeders, and in-hive frame feeders, each with its own design.

Hive Body Width: 8-Frame vs. 10-Frame

While the 10-frame hive body is the traditional standard, an 8-frame version is a popular alternative. This is a fundamental configuration choice rather than a simple add-on.

The primary reason to choose an 8-frame hive is weight reduction. A deep 8-frame box full of honey is significantly lighter than its 10-frame counterpart, making it a common choice for beekeepers with back problems or lifting limitations.

Understanding the Trade-offs

No extension is a perfect solution. An expert beekeeper understands the potential downsides of each tool.

The Queen Excluder Debate

Queen excluders are effective but controversial. Some beekeepers find that the bees are reluctant to work their way through the barrier, creating a "bottleneck" that can reduce the speed of honey production. The metal wires can also occasionally damage a worker bee's wings.

Screened vs. Solid Bottom Boards

A screened bottom board provides excellent ventilation, which can help reduce moisture buildup in humid climates. However, in very cold winters, the increased airflow can create a draft that makes it harder for the colony to maintain its cluster temperature.

The 8-Frame Weight Advantage vs. Standardization

The key benefit of an 8-frame hive is that it's lighter and easier to handle. The trade-off is that 10-frame equipment is the industry standard. It is far more common and often more readily available, making it easier to purchase or exchange equipment with other beekeepers.

Making the Right Choice for Your Goal

Your decision to use an extension should be driven by a specific management goal.

- If your primary focus is maximizing a clean honey harvest: Use a queen excluder to ensure brood-free honey supers, but monitor it to ensure it is not overly restricting bee traffic.

- If your primary focus is colony health and IPM: Prioritize a screened bottom board with a varroa tray for accurate and easy mite monitoring.

- If your primary focus is physical accessibility and ease of lifting: Choose an 8-frame hive configuration from the very start of your beekeeping journey.

- If your primary focus is supporting a new or weak colony: An entrance reducer is an essential, non-negotiable tool to help the bees defend their home.

Ultimately, mastering these optional components transforms beekeeping from a passive activity into a responsive, strategic craft.

Summary Table:

| Extension | Primary Function | Key Benefit | Potential Trade-off |

|---|---|---|---|

| Queen Excluder | Confines queen to brood boxes | Ensures brood-free honey supers | May slow honey production ("honey barrier") |

| Entrance Reducer | Narrows hive entrance | Aids defense for weak/new hives; helps winter insulation | Must be removed when hive is strong/active |

| Varroa Mite Tray | Monitors Varroa mite levels | Essential for Integrated Pest Management (IPM) | Can increase draft in very cold climates |

| 8-Frame Hive Body | Reduces box weight | Easier lifting and handling | Less common than 10-frame (industry standard) |

Ready to equip your apiary with the right hive extensions?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable components needed for strategic hive management. From queen excluders and screened bottom boards to 8-frame hive bodies, our wholesale-focused operations ensure you get the reliable equipment your business depends on.

Contact our expert team today to discuss your specific needs and learn how HONESTBEE can support your success.

Visual Guide

Related Products

- Professional Plastic Queen Excluder for Modern Beekeeping

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Wooden Queen Bee Excluder for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What is the significance of using queen excluders in tropical bee management? Boost Honey Purity & Colony Stability

- How do queen excluders assist in the management of honey production? Optimize Your Harvest Purity and Efficiency

- What is the core function of a Queen Excluder in royal jelly production? Boost Yields with Behavioral Management

- What are the main arguments in the debate over using queen excluders? Efficiency vs. Natural Hive Management

- What are the disadvantages of using metal queen excluders? Key Insights for Apiary Management