The most critical precaution when melting beeswax is to use indirect heat and carefully control the temperature. Because beeswax is flammable and sensitive to overheating, it should never be placed directly on a stove burner or open flame. Exceeding its flashpoint (around 400°F) poses a significant fire hazard, while heating it above 175°F can degrade its natural properties, color, and aroma.

The core challenge in melting beeswax isn't the melting itself, but managing its two primary risks: its flammability at high temperatures and its tendency to degrade at moderate temperatures. Therefore, your entire process must be built around the non-negotiable principle of slow, indirect, and constantly monitored heat.

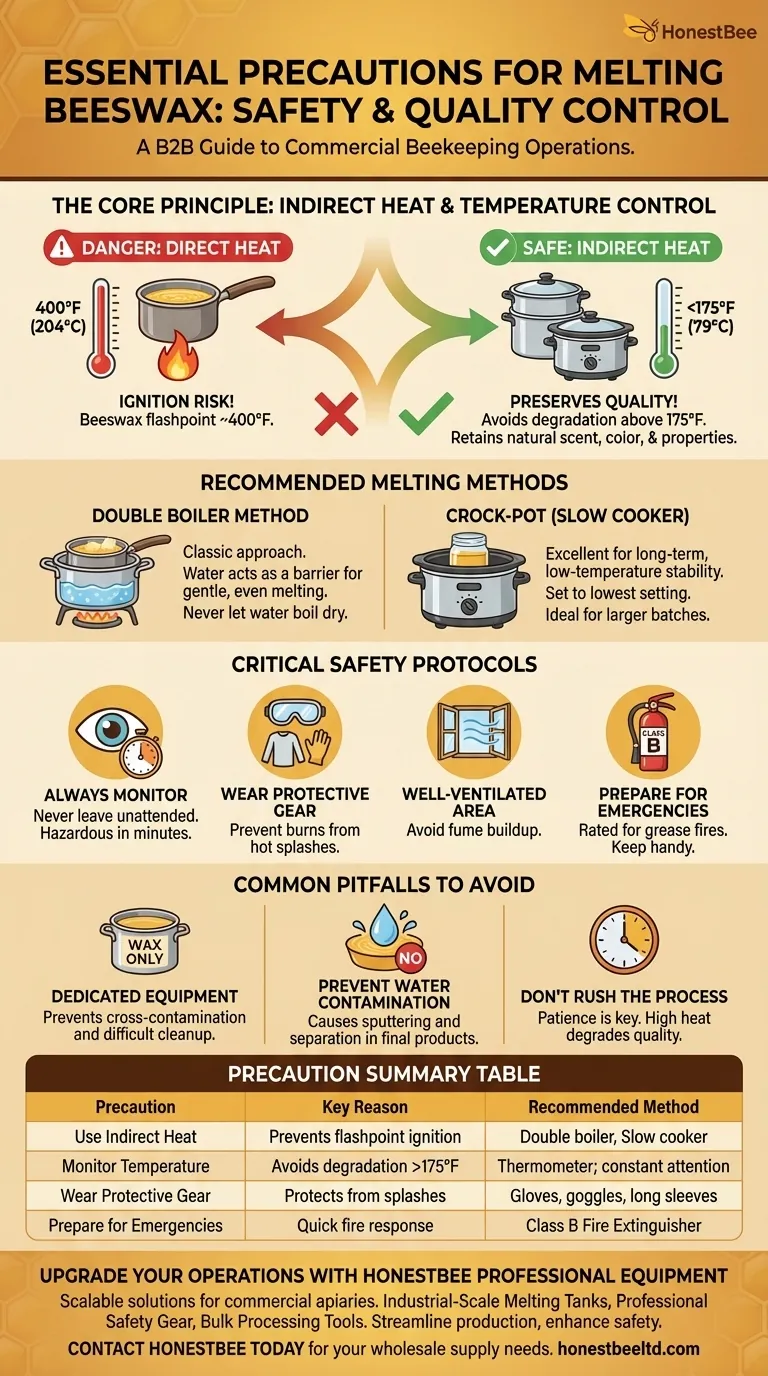

The Core Principle: Why Indirect Heat is Essential

Melting beeswax seems simple, but applying heat directly is a common and dangerous mistake. Understanding the "why" behind indirect heating methods is the key to both safety and quality.

The Inherent Fire Risk

Beeswax is a flammable material. When heated directly on a flame or a hot electric burner, its temperature can rise uncontrollably and very quickly.

At approximately 400°F (204°C), beeswax can ignite. This creates a dangerous grease-fire situation that cannot be extinguished with water.

Preserving the Wax's Quality

Beyond the immediate fire hazard, overheating damages the beeswax itself.

To retain its desirable natural honey scent, light color, and beneficial anti-microbial properties, the wax should not be heated above 175°F (79°C). Excessive heat will darken the wax and diminish its aroma.

Recommended Melting Methods

Both recommended methods place a barrier between the primary heat source and the container holding the wax, giving you the control you need.

The Double Boiler Method

A double boiler is the classic approach. You can create a makeshift one by placing a smaller, heat-proof pot or glass container inside a larger pot filled with a few inches of water.

The heat from the stove boils the water, which in turn gently and evenly melts the wax in the inner container. Never let the water boil away completely.

The Crock-Pot (Slow Cooker) Method

Using a crock-pot is an excellent method for maintaining a stable, low temperature over a long period.

Place your beeswax into a container (like a glass jar) and set it inside the crock-pot. Set the crock-pot to its lowest setting and allow the wax to melt slowly.

Critical Safety Protocols

Regardless of your chosen method, these safety rules are universal and must be followed without exception.

Always Monitor the Process

Never leave melting beeswax unattended. A situation can become hazardous in a matter of minutes. Once the wax is fully melted, remove it from the heat source immediately.

Wear Protective Gear

Hot wax can splash and cause severe burns. Always wear safety goggles, long sleeves, and heat-resistant gloves to protect your eyes and skin.

Prepare for Emergencies

Work in a well-ventilated area to avoid any buildup of fumes. Most importantly, always keep a fire extinguisher rated for grease fires (Class B) within easy reach.

Common Pitfalls to Avoid

Beyond the major safety risks, a few practical details will ensure a smooth process and a better final product.

Use Dedicated Equipment

Beeswax is notoriously difficult to clean from pots, jars, and utensils. It's highly advisable to designate specific equipment exclusively for your beeswax projects. This prevents contamination of your cookware and saves significant cleanup effort.

Prevent Water Contamination

Be careful not to splash water from your double boiler into the melting beeswax. Water in your final product can cause sputtering in candles or separation in balms and lotions.

Don't Rush the Process

The key to melting beeswax is patience. Rushing by turning up the heat is the primary cause of overheating, which degrades quality and increases risk. Allow the wax to melt slowly and gently.

Making the Right Choice for Your Goal

Your equipment and the scale of your project will guide your method, but the principles of safety remain the same.

- If your primary focus is a small, one-time project: A simple DIY double boiler on your stovetop is a fast and effective method, provided you monitor it constantly.

- If your primary focus is working with larger batches or infusing oils: A dedicated crock-pot is the superior choice for its unmatched temperature stability and safety.

Ultimately, treating this natural material with respect for its properties is the surest path to a safe process and a beautiful result.

Summary Table:

| Precaution | Key Reason | Recommended Method |

|---|---|---|

| Use Indirect Heat | Prevents wax from reaching flashpoint (~400°F) and igniting | Double boiler or slow cooker |

| Monitor Temperature | Avoids degradation of color/aroma above 175°F | Thermometer; never leave unattended |

| Wear Protective Gear | Protects from hot wax splashes | Gloves, goggles, long sleeves |

| Prepare for Emergencies | Quick response to potential fires | Keep Class B fire extinguisher nearby |

Upgrade Your Beekeeping Operations with Professional-Grade Equipment

Melting beeswax safely and efficiently is crucial for producing high-quality candles, balms, and cosmetics. As a commercial apiary or beekeeping equipment distributor, you need reliable, scalable solutions to handle large batches without compromising safety or quality.

HONESTBEE supplies the durable, commercial-grade equipment you need:

- Industrial-Scale Melting Tanks: Designed for precise, indirect heat control and easy cleanup.

- Professional Safety Gear: Protect your team with heat-resistant gloves and goggles.

- Bulk Wax Processing Tools: Streamline your production with equipment built for volume.

We understand the challenges of managing beeswax at scale. Let us provide the wholesale-focused equipment solutions that enhance your productivity and safeguard your operation.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color

- What are the steps for using a wax melter to melt beeswax? Master Safe, Efficient Beeswax Processing

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business