Working with molten beeswax requires a methodical and safety-first approach. The primary dangers are severe burns from hot wax and the risk of fire, as beeswax is a flammable material. The core safety precautions involve controlling the heat source using a double boiler, never leaving melting wax unattended, and ensuring your workspace is properly prepared and protected.

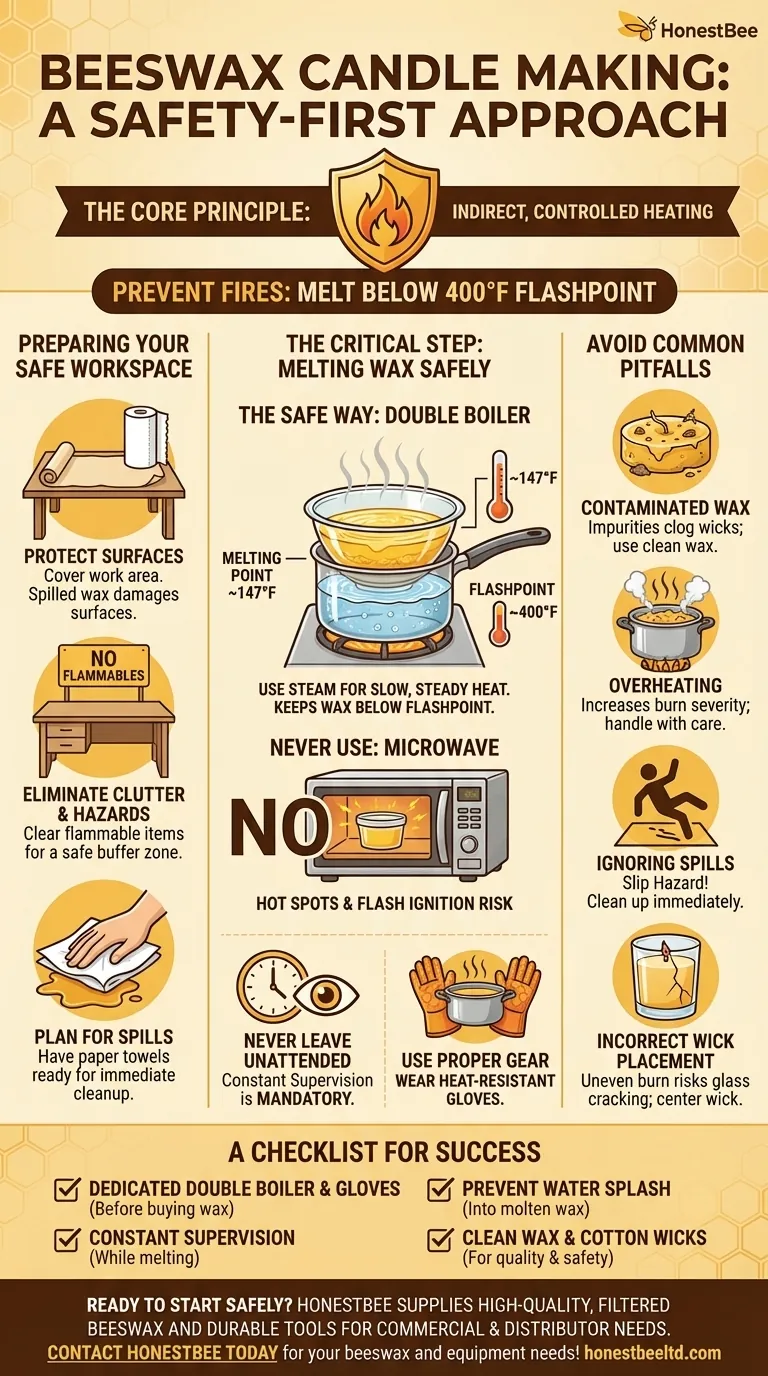

The fundamental principle of beeswax candle safety is indirect, controlled heating. By using a dedicated double boiler, you eliminate the primary risk of the wax reaching its 400°F flashpoint, which is the direct cause of most candle-making fires.

Preparing a Safe Workspace

Before you begin melting anything, the proper setup of your environment is a critical first step. This minimizes risk and makes the entire process smoother.

Protect Your Surfaces

Cover your work area with parchment paper or several layers of paper towels. Spilled wax is difficult to clean and can damage surfaces.

Eliminate Clutter and Fire Hazards

Ensure your workspace is clear of any flammable items, including paper towels not being used for surface protection. This creates a safe buffer zone around your heating element.

Plan for Spills

Have paper towels ready to immediately wipe up any drips or spills. Hot wax can spread quickly, and cleaning it up promptly prevents larger messes and potential accidents.

The Critical Step: Melting the Wax Safely

How you melt the wax is the most important safety decision you will make. Direct heat is the primary cause of accidents.

Why a Double Boiler is Non-Negotiable

A double boiler is the safest method because it uses steam to provide slow, steady, and indirect heat. This keeps the wax temperature well below its flashpoint.

You can create a makeshift double boiler using an old pot with a few inches of water and a heat-resistant glass bowl or smaller pot resting on top.

Crucially, the beeswax melts at around 147°F, while its flashpoint (where it can ignite) is approximately 400°F. A double boiler makes it nearly impossible to reach this dangerous temperature.

Never Use a Microwave

Microwaving wax is extremely dangerous. It can create super-heated hot spots that can cause the wax to flash ignite, either in the microwave or when you move the container.

Constant Supervision is Mandatory

Never walk away from melting wax, even for a moment. The process requires your full attention.

Use Proper Protective Equipment

Always wear heat-resistant gloves when handling the pot or bowl containing molten wax. Burns from hot wax can be severe.

Common Pitfalls to Avoid

Beyond the core rules, several common mistakes can compromise safety and the quality of your final candle.

Using Contaminated Wax

Ensure your beeswax is clean and free of debris. Impurities, especially from unfiltered raw wax, can travel up the wick as the candle burns, clogging the wick and causing it to extinguish or burn improperly.

Overheating the Wax

Even if the wax doesn't reach its flashpoint, overheating it is dangerous. It increases the severity of potential splash burns and makes the molten wax harder to handle safely.

Ignoring Spills

A small drip of wax on the floor can quickly cool and become a significant slip hazard. Clean up all spills immediately and thoroughly.

Incorrect Wick Placement

An off-center wick will cause the candle to burn unevenly. In glass container candles, this can cause one side of the glass to become dangerously hot, creating a risk of the glass cracking. Use a pencil or clothespin to hold the wick perfectly centered while the wax cools.

A Checklist for a Safe Process

Apply these principles to ensure a safe and successful outcome for your project.

- If you are setting up for the first time: Prioritize acquiring a dedicated double boiler and heat-resistant gloves before you even purchase wax.

- If you are actively melting wax: Keep your full attention on the pot, ensure the water in the bottom pot does not boil dry, and prevent any water from splashing into the molten wax.

- If you are concerned about the final product: Use only clean, filtered beeswax and 100% cotton wicks to prevent clogging and ensure a safe, even burn.

By treating beeswax with respect and following these deliberate steps, you can confidently transform a raw material into a safe and beautiful candle.

Summary Table:

| Safety Precaution | Key Detail | Why It's Important |

|---|---|---|

| Use a Double Boiler | Melts wax indirectly with steam. | Prevents wax from reaching its 400°F flashpoint and igniting. |

| Never Leave Unattended | Stay with the melting wax at all times. | Allows for immediate response to spills or overheating. |

| Wear Heat-Resistant Gloves | Protect hands when handling hot containers. | Prevents severe burns from molten wax splashes. |

| Prepare Workspace | Cover surfaces, clear flammable items. | Minimizes fire risk and contains potential spills. |

Ready to start your candle-making project safely?

HONESTBEE supplies beekeeping supplies and equipment, including high-quality, filtered beeswax and durable candle-making tools, to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the reliable materials you need for a safe and successful production process.

Contact HONESTBEE today to discuss your beeswax and equipment needs!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper

- At what temperature does honey flow? Preserve Quality with the Perfect 95°F Sweet Spot

- Why is heating honey sometimes necessary? The Essential Guide to Processing & Quality

- What is the effect of heating on honey? Preserve Quality with Controlled Warming

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality