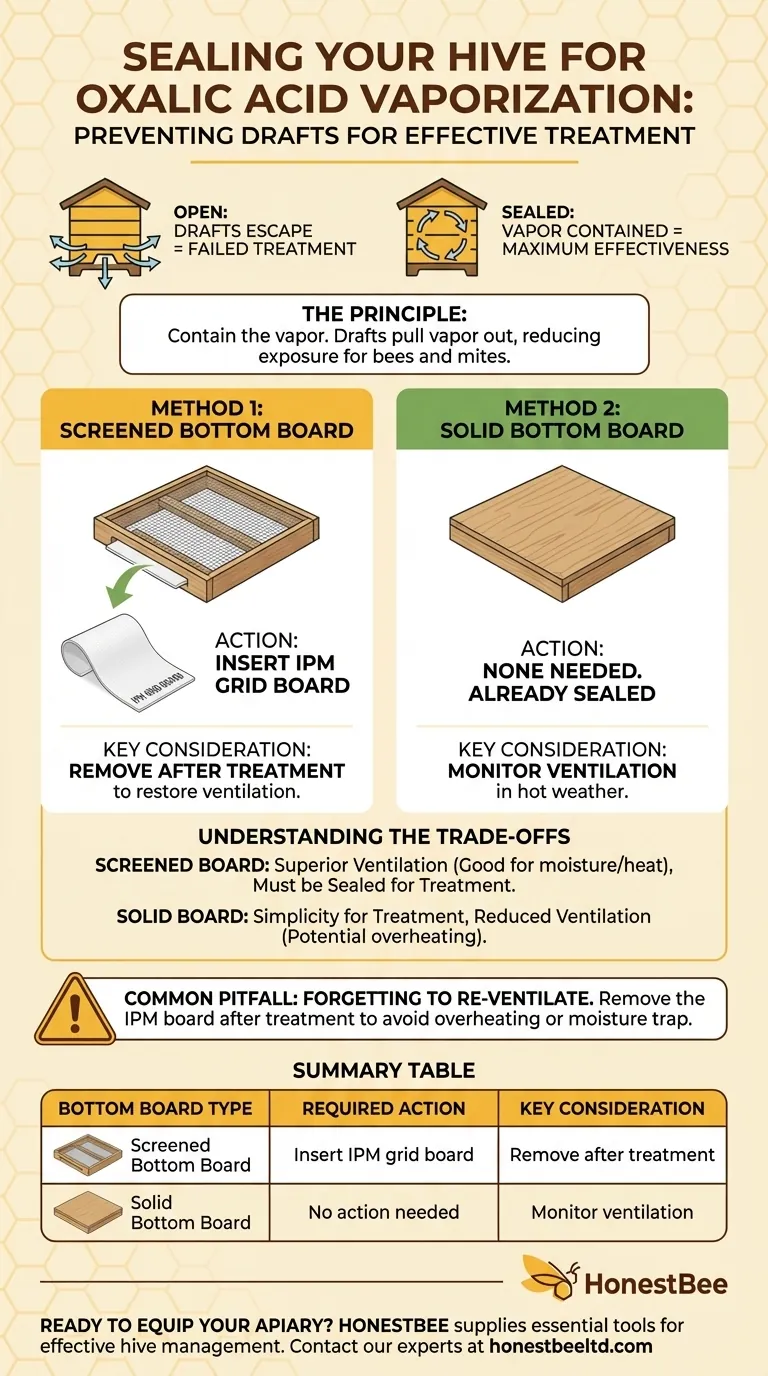

To effectively treat your hive with oxalic acid vapor, you must reduce airflow from the bottom. The most common and effective way to do this is by sliding in the IPM grid board (the flexible white board) that comes with a screened bottom board. If your hive uses a solid bottom board, it is already sealed and ready for treatment without any extra steps.

The core principle is simple: effective Varroa mite treatment with oxalic acid vapor depends on containing the vapor within the hive. Any draft will pull the vapor out prematurely, drastically reducing its effectiveness and wasting your efforts.

The Principle: Why Sealing the Hive is Non-Negotiable

Oxalic acid vaporization is a highly effective method for controlling phoretic Varroa mites—the mites physically attached to adult bees. However, its success hinges entirely on achieving and maintaining a sufficient concentration of the vaporized acid within the hive cluster.

The Impact of Drafts on Treatment

Drafts, especially those from an open screened bottom board, create a chimney effect. As you apply the vapor, this airflow immediately begins pulling it out of the hive.

This premature venting means the bees, and the mites on them, are not exposed to the acid for the required duration, leading to a failed or incomplete treatment.

The Goal: Maximum Vapor Concentration

By temporarily sealing the bottom of the hive, you trap the hot oxalic acid vapor.

This containment forces the vapor to circulate throughout the hive, ensuring it contacts the bees and the mites they carry. The vapor then cools and re-crystalizes, depositing a fine layer of oxalic acid crystals on the bees' bodies, which is lethal to the mites.

Your Sealing Options: A Direct Comparison

You have two primary, straightforward options for preparing your hive for vaporization. The right choice simply depends on the equipment you already use.

Using an IPM Grid Board

Most modern beekeepers use a screened bottom board for ventilation and passive mite monitoring. These almost always come with a removable plastic or corrugated plastic board, often called an IPM board, mite tray, or sticky board.

Its purpose for treatment is to temporarily convert your screened bottom into a solid one. You simply slide it into the provided slot before you begin the vaporization process.

Using a Solid Bottom Board

A solid bottom board is a traditional piece of hive equipment without a screen. If your hives are configured with solid bottom boards, you do not need to take any extra steps.

The hive is already sealed from the bottom, making it ready for vaporization by default.

Understanding the Trade-offs

Choosing between a screened or solid bottom board has implications beyond mite treatment. Understanding these helps you manage your colony effectively throughout the year.

The Screened Bottom Board: Superior Ventilation

The primary advantage of a screened bottom board is superior air circulation. This helps reduce moisture and condensation inside the hive, especially during winter, and helps keep the colony cool during hot summers.

However, its key disadvantage is that it must be closed off for an oxalic acid vaporization treatment to be effective.

The Solid Bottom Board: Simplicity for Treatment

A solid bottom board’s main advantage is its simplicity. It requires no extra steps for vaporization and offers better heat retention in colder climates.

The trade-off is reduced ventilation, which can become a liability in very hot and humid weather, potentially causing the colony to overheat or struggle with moisture control.

The Most Common Pitfall: Forgetting to Re-Ventilate

After your oxalic acid treatment is complete, it is critical to remove the IPM grid board. Forgetting to do so negates the ventilation benefits of the screened bottom board.

Leaving the board in during hot weather can lead to the colony overheating, and leaving it in during winter can trap excess moisture. Make its removal part of your post-treatment checklist.

Making the Right Choice for Your Goal

Your equipment determines your process, but the goal remains the same: a sealed hive for an effective treatment.

- If you use a screened bottom board: Your standard procedure must be to slide in the IPM grid board before every vaporization and remove it after the treatment is complete.

- If you use a solid bottom board: You are already prepared for treatment, but you should remain mindful of your colony's ventilation needs, especially during peak summer heat.

- If you have neither an IPM board nor a solid bottom: A temporary, non-flammable barrier like a piece of plywood cut to size can work in a pinch, but acquiring a proper IPM board for your setup is the correct long-term solution.

Properly sealing your hive is a simple step that transforms an oxalic acid treatment from a hopeful guess into a reliable defense for your bees.

Summary Table:

| Bottom Board Type | Required Action for Vaporization | Key Consideration |

|---|---|---|

| Screened Bottom Board | Insert IPM grid board | Remove board after treatment to restore ventilation |

| Solid Bottom Board | No action needed | Monitor hive ventilation in hot weather |

Ready to equip your apiary for successful mite treatments? HONESTBEE supplies commercial beekeepers and equipment distributors with the essential tools for effective hive management, including screened bottom boards with IPM grids and other vital supplies. Ensure your Varroa treatments are consistently effective—contact our wholesale experts today to discuss your equipment needs!

Visual Guide

Related Products

- Oxalic Acid Vaporizer 12V for Bee Varroa Mite Treatment

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Compact Circular Bee Mite Treatment Dispenser

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Professional Insulated Winter Hive Wrap for Beekeeping

People Also Ask

- What is the role of oxalic acid in plants? A Key to Plant Defense and Internal Regulation

- Under what specific conditions should oxalic acid be used for beehive mite control? Best Practices for Late Fall Care

- How is the oxalic acid solution prepared for vaporization? No Solution Needed—Use Dry Crystals for Varroa Control

- What is the role of using a sugar water solution for oxalic acid? Enhance Mite Control with Better Adhesion

- What are the registered application methods for oxalic acid in honey bee colonies? 3 Proven Ways to Control Varroa Mites