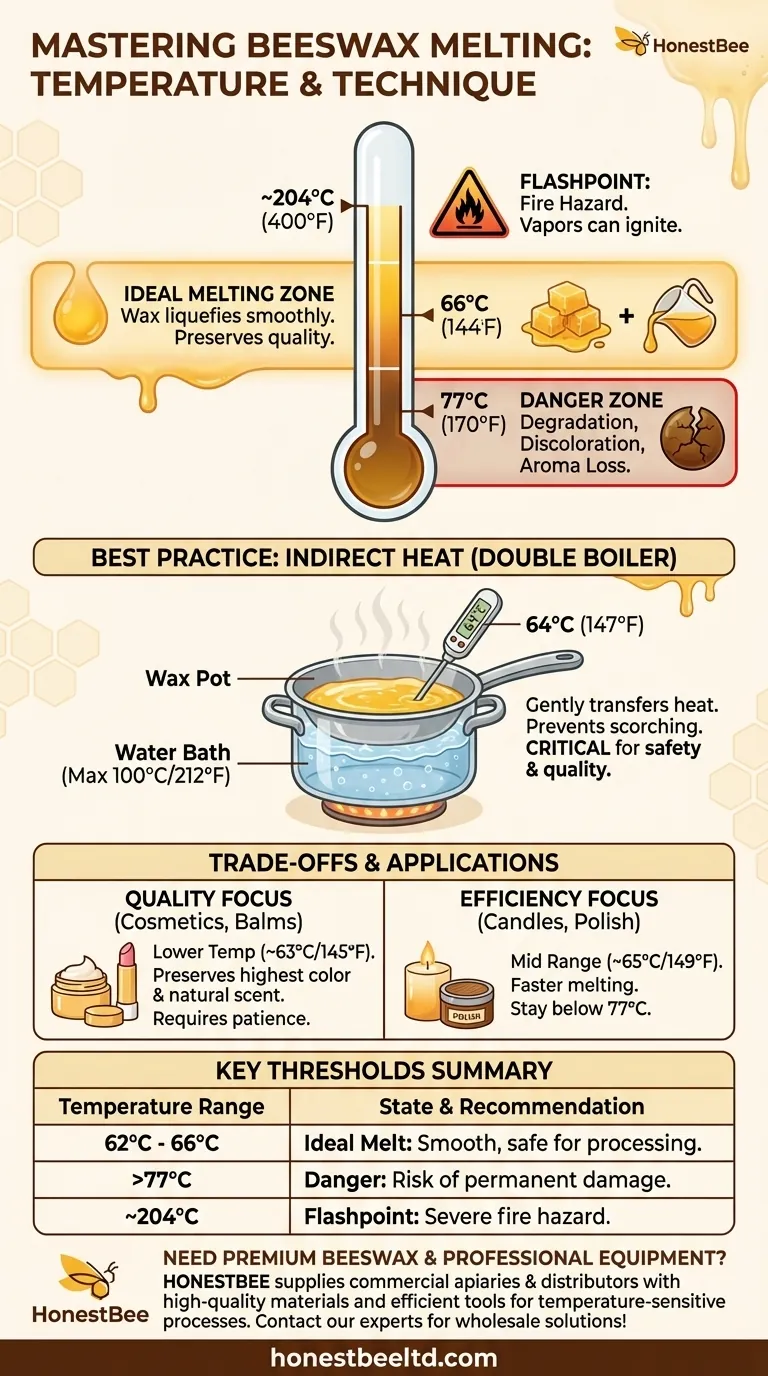

In short, pure beeswax melts at a relatively low temperature, typically between 62°C to 64°C (144°F to 147°F). While it will begin to liquefy around 61°C (143°F), achieving a smooth, fully melted consistency happens within this narrow range. The key to working with beeswax is not just reaching this temperature, but also not exceeding it significantly.

The challenge of melting beeswax isn't about getting it hot, but about applying gentle, controlled heat. Exceeding its melting point by even a small margin can degrade the wax, permanently altering its color and stripping away its delicate natural aroma.

The Science of a Beeswax Melt

Beeswax is a natural product, a complex mixture of several different compounds created by bees. This composition is why it melts over a range of temperatures, not at a single, precise point like a pure chemical.

Key Temperature Thresholds

The Ideal Melting Zone: 62°C – 66°C (144°F – 151°F) This is the target range for melting beeswax. At these temperatures, the wax will liquefy efficiently, making it easy to strain, pour, or mix with other ingredients.

The "Danger Zone": Above 77°C (170°F) Heating beeswax beyond this point is where damage occurs. The wax can darken, often turning a dull brown, and its signature sweet, honey-like scent will be lost. This change is irreversible.

Best Practices for Safe and Effective Melting

Use Indirect Heat Never place a container of beeswax directly on a heat source. This creates hot spots that will quickly overheat and scorch the wax. The industry-standard method is using a double boiler.

The Role of a Double Boiler A double boiler uses steam to transfer heat gently and evenly. By placing a pot with your beeswax inside a larger pot of simmering water, you ensure the wax temperature can never exceed the boiling point of water (100°C or 212°F), providing a critical safety buffer.

Monitor the Temperature For consistent results, use a thermometer (such as a candy or digital probe thermometer) to monitor the wax. This allows you to hold the temperature within the ideal melting zone without accidentally crossing into the danger zone.

Understanding the Trade-offs

Efficiency vs. Quality Pushing the temperature higher will melt the wax faster, but you risk degrading its quality. Keeping the temperature at the lower end of the melting range preserves the color and scent perfectly but requires more patience.

Safety and Flashpoint While the discoloration temperature is low, the flashpoint of beeswax—the temperature at which its vapors can ignite—is much higher, around 204°C (400°F). While unlikely to be reached with a double boiler, it highlights the severe fire hazard of melting beeswax over direct, uncontrolled heat.

Making the Right Choice for Your Goal

To achieve the best results, tailor your heating method to your final purpose.

- If your primary focus is cosmetics or balms: Keep the temperature at the low end of the melting range (around 63°C or 145°F) to preserve the highest quality, color, and natural aroma.

- If your primary focus is candlemaking or wood polish: You can melt the wax more quickly in the middle of the ideal range (around 65°C or 149°F), but always stay well below the 77°C (170°F) limit.

- If your primary focus is safety and consistency: Always use a double boiler and a thermometer, regardless of the project.

Mastering beeswax is about mastering temperature control.

Summary Table:

| Temperature Range | State & Recommendation |

|---|---|

| 62°C - 66°C (144°F - 151°F) | Ideal Melting Zone: Wax liquefies smoothly. Safe for straining, pouring, and mixing. |

| Above 77°C (170°F) | Danger Zone: Risk of degradation, discoloration, and loss of natural aroma. |

| ~204°C (400°F) | Flashpoint: Wax vapors can ignite. Emphasizes the critical need for controlled, indirect heat. |

Need reliable, high-quality beeswax or professional melting equipment for your commercial apiary or distribution business? HONESTBEE supplies beekeepers and distributors with the premium supplies and efficient equipment needed to master temperature-sensitive processes like wax rendering. We help you protect your product quality and maximize your operational efficiency. Contact our wholesale experts today to discuss your specific needs and volume pricing!

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How does a honey screw press operate to separate honey from wax? Boost Your Apiary Efficiency

- How can the use of specialized beekeeping hardware like propolis grids and wax presses improve production? Scale Now

- What happens to the wax after extraction by the Wax Screw Press? Efficient Post-Extraction Processing Guide

- What equipment is used to separate beeswax from honey in cappings? Match the Right Tool to Your Apiary's Scale

- What is the primary function of a honey screw press? Maximize Yield with Advanced Cold Press Separation Technology