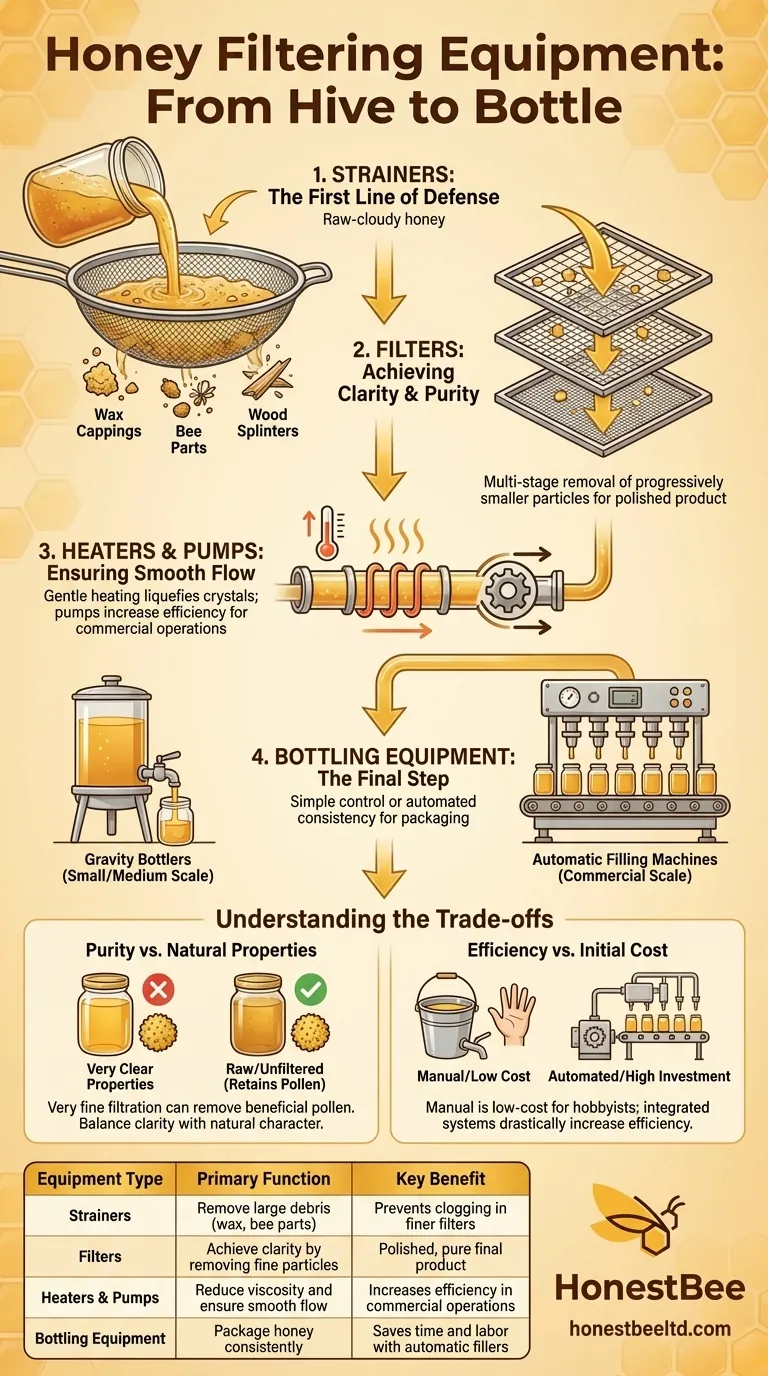

At its core, honey filtering relies on a system of key equipment. This includes strainers for large debris, progressively finer filters for smaller particles, pumps to manage flow, and bottling machines for final packaging. Each component plays a specific role in transforming raw, harvested honey into a clean, pure, and marketable product.

The goal of a honey filtering system is not simply to clean the honey, but to do so efficiently while preserving its natural quality. The right combination of equipment removes undesirable impurities like wax and bee parts, ensuring a stable, visually appealing final product ready for the consumer.

The Core Components of a Honey Filtering System

A complete filtering setup is more than a single machine; it's a series of stages, each with specialized equipment. Understanding the role of each component is essential for producing high-quality honey.

Strainers: The First Line of Defense

The process begins with straining. Strainers are coarse mesh screens designed to catch the largest impurities immediately after extraction.

This initial step removes visible debris such as wax cappings, bee parts, and wood splinters from the hive frames. It prevents larger particles from clogging the finer filters later in the process.

Filters: Achieving Clarity and Purity

After initial straining, honey moves through a series of progressively finer filters. These mesh screens are designed to remove smaller suspended particles.

This multi-stage approach ensures that the system doesn't get overwhelmed. By starting with a coarser filter and moving to a finer one, the process is more efficient and effective, resulting in a clear, polished final product.

Heaters and Pumps: Ensuring Smooth Flow

Honey is naturally viscous and can crystallize, making it difficult to process. Gentle heating is often applied to liquefy any crystals and reduce viscosity.

This ensures the honey flows smoothly and evenly through the filters. In larger operations, pumps are used to move the honey through the system, increasing speed and efficiency, especially when pressure systems are used to push the honey through very fine filters.

Bottling Equipment: The Final Step

Once filtered, the honey must be packaged. Gravity bottlers, which use the weight of the honey to fill jars, are common in small to medium operations for their simplicity and control.

For commercial-scale production, automatic filling machines are used. These systems can fill multiple bottles at once, saving significant time and labor while ensuring consistent fill levels.

Understanding the Trade-offs

Choosing the right equipment involves balancing purity with the preservation of honey's natural character. An overly aggressive approach can be counterproductive.

Purity vs. Natural Properties

The primary goal is to remove unwanted debris. However, very fine filtration, especially when combined with high heat, can also remove naturally occurring and beneficial components like pollen.

For producers marketing "raw" or "unfiltered" honey, a less intensive straining process is preferable. For those seeking maximum clarity and a long shelf life, a more thorough filtration system is necessary.

Efficiency vs. Initial Cost

A simple bucket strainer and a gravity bottler are inexpensive and effective for a hobbyist. They require more manual labor and are slower but have a very low barrier to entry.

Conversely, a fully integrated system with heaters, pumps, and automatic bottlers represents a significant investment. This equipment drastically increases efficiency and consistency, making it essential for any commercial operation.

Maintenance: Protecting Your Investment

Proper equipment maintenance is non-negotiable for ensuring honey quality and extending the life of your machinery.

All components must be washed regularly with warm water and a mild detergent to prevent residue buildup. After cleaning, every part must be dried thoroughly to prevent corrosion. Regular inspection for worn filters, leaks, or loose fittings is critical for reliable operation.

Making the Right Choice for Your Goal

The ideal equipment setup depends entirely on the scale and goals of your beekeeping operation.

- If your primary focus is small-scale or hobby production: A set of simple, coarse-to-fine bucket strainers and a gravity bottler is the most practical and cost-effective solution.

- If your primary focus is commercial production for retail: An integrated system with gentle heating, pumps, and an automatic filling machine is essential for achieving consistency, efficiency, and regulatory compliance.

Ultimately, investing in the right filtering equipment empowers you to produce a clean, stable, and high-quality product that reflects the hard work of both you and your bees.

Summary Table:

| Equipment Type | Primary Function | Key Benefit |

|---|---|---|

| Strainers | Remove large debris (wax, bee parts) | Prevents clogging in finer filters |

| Filters | Achieve clarity by removing fine particles | Polished, pure final product |

| Heaters & Pumps | Reduce viscosity and ensure smooth flow | Increases efficiency in commercial operations |

| Bottling Equipment | Package honey consistently | Saves time and labor with automatic fillers |

Ready to optimize your honey production with professional-grade filtering equipment? HONESTBEE specializes in supplying durable, efficient beekeeping supplies and equipment tailored for commercial apiaries and distributors. Whether you're scaling your operation or improving product consistency, our wholesale-focused solutions ensure you get the right tools for pure, marketable honey. Contact us today to discuss your needs and elevate your honey filtering process!

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- What are the benefits of using a honey filtering machine? Boost Purity, Efficiency & Market Appeal

- How do honey filtering machines improve the consistency and appearance of honey? Enhancing Purity and Market Value

- What is the primary function of multi-stage precision filtration equipment? Enhancing Honey Clarity and Consistency

- What function does honey filtration and clarification equipment serve? Enhance Purity and Value in Your Production

- Why is a precision moisture control filtration system critical for the industrial production of honey? | HONESTBEE Guide

- What role does large-scale honey concentration and filtration equipment play? Elevate Your Regional Brand Standards

- What are the benefits of using a honey filtering machine for bulk processing? Scale Your Apiary with Efficiency & Quality

- How do specialized honey processing and filtration equipment support consumer trust in honey quality? Build Brand Loyalty