The Honey Harvest's Hidden Bottleneck

Every beekeeper knows the feeling. The air in the honey house is thick with the sweet, warm scent of beeswax and fresh honey. Supers are stacked high, a testament to a season of hard work by both bee and keeper. This moment is a reward.

But it's also the start of a race.

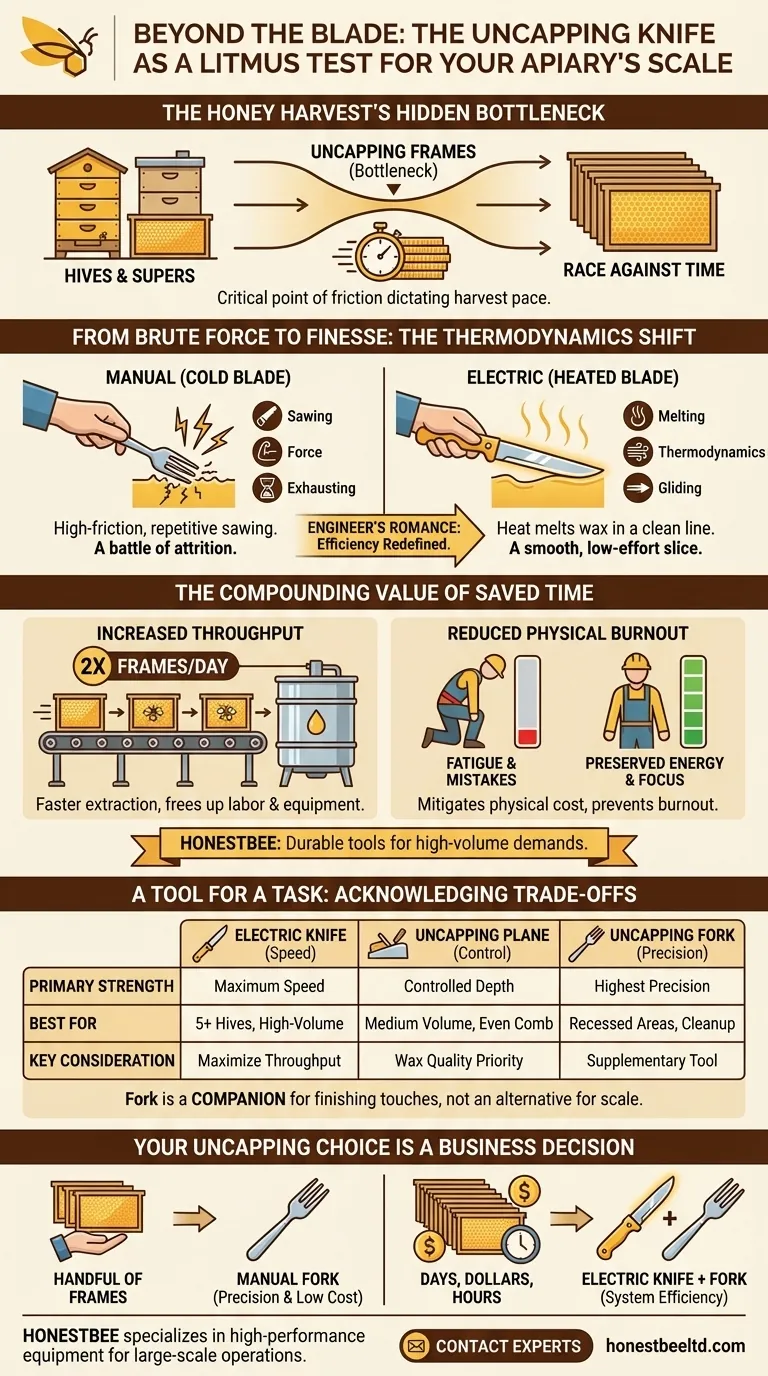

Between the hive and the extractor lies the most laborious, time-consuming, and physically demanding step: uncapping the frames. For a small operation, it's a satisfying ritual. For a commercial apiary, it's a critical bottleneck—a point of friction that dictates the pace of the entire harvest. The decision of how to approach this task is not just about tools; it's about the psychology of your operation and your ambition to scale.

From Brute Force to Finesse: The Thermodynamics of a Heated Blade

The traditional method of uncapping, using a cold knife or fork, is a battle of attrition. It relies on sharp edges and physical force to saw, scrape, and tear through the wax cappings. It’s effective, but it’s also slow and exhausting. Each frame is a physical tax on your hands, wrists, and patience.

An electric uncapping knife changes the fundamental physics of the problem.

It's not about cutting anymore. It's about thermodynamics. The thermostatically controlled blade doesn't tear; it glides. By introducing heat, the knife melts the wax in a clean, continuous line. The task is transformed from a high-friction, repetitive sawing motion into a smooth, low-effort slice. You’re no longer fighting the wax; you’re persuading it to yield.

This is the engineer's romance: a simple application of heat that completely redefines the efficiency of an entire system.

The Compounding Value of Saved Time

In a commercial operation, time is not just a resource; it's inventory. The hours saved by an electric knife are not merely a convenience—they are a direct input to profitability.

- Increased Throughput: Reducing uncapping time by half (or more) means doubling the number of frames you can process in a day. This allows you to extract honey faster, freeing up equipment and labor for other critical apiary tasks.

- Reduced Physical Burnout: The repetitive strain of manual uncapping leads to fatigue. Fatigue leads to mistakes, slower work, and, ultimately, burnout during the most critical part of the season. A heated knife mitigates this physical cost, preserving the operator's energy and focus.

For commercial apiaries and distributors, equipment isn't a hobbyist expense—it's a capital investment in operational efficiency. HONESTBEE understands this distinction, supplying durable tools engineered to withstand the demands of a high-volume harvest.

A Tool for a Task: Acknowledging the Trade-offs

Of course, no tool is a universal solution. The electric knife’s design is optimized for speed, which comes with deliberate trade-offs. Its broad, heated blade is less precise than a manual fork, especially on uneven comb or in recessed areas. It requires a power source, a logistical consideration in any honey house setup.

The key is to match the tool to the scale of the job.

| Tool | Primary Strength | Best For | Key Consideration for Commercial Use |

|---|---|---|---|

| Electric Knife | Maximum Speed | 5+ Hives, High-Volume Processing | The standard for maximizing throughput and minimizing labor per frame. |

| Uncapping Plane | Controlled Depth | Medium Volume, Even Comb | Good for operations prioritizing wax quality and minimizing honey loss. |

| Uncapping Fork | Highest Precision | Recessed Areas, Cleanup | An essential supplementary tool, not a primary one for scale. |

For a commercial beekeeper, the fork is not an alternative to the electric knife; it's a companion for the finishing touches the knife can't manage.

Your Uncapping Choice Is a Business Decision

Ultimately, the tool you choose to uncap your honey is a litmus test for the scale of your operation.

If you measure your harvest in a handful of frames, the precision and low cost of a manual fork make perfect sense. But if you measure your harvest in days, dollars, and employee hours, the system demands efficiency. The bottleneck must be opened.

For commercial apiaries and equipment distributors looking to optimize their harvesting workflow, choosing the right tools is the first step. At HONESTBEE, we specialize in supplying durable, high-performance equipment designed for the demands of large-scale operations. Contact Our Experts

Visual Guide

Related Products

- Professional Compact Multi-Function Uncapping Knife for Beekeeping

- Professional Stainless Steel Double-Sided Honey Uncapping Knife

- Stainless Steel Pivoting Honey Uncapping Fork with Plastic Handle

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

- All-Stainless Steel Pivoting Honey Uncapping Fork for Beekeeping

Related Articles

- How to Uncap Honeycomb Safely: Professional Methods for Maximum Yield and Wax Preservation

- How to Choose the Right Hive Tool for Your Beekeeping Needs

- Comprehensive Guide to Uncapping Honey Frames for Beekeepers

- Beyond the Pry Bar: The Physics and Psychology of the J-Hook Hive Tool

- How to Choose the Right Beeswax Uncapping Tool for Your Beekeeping Needs