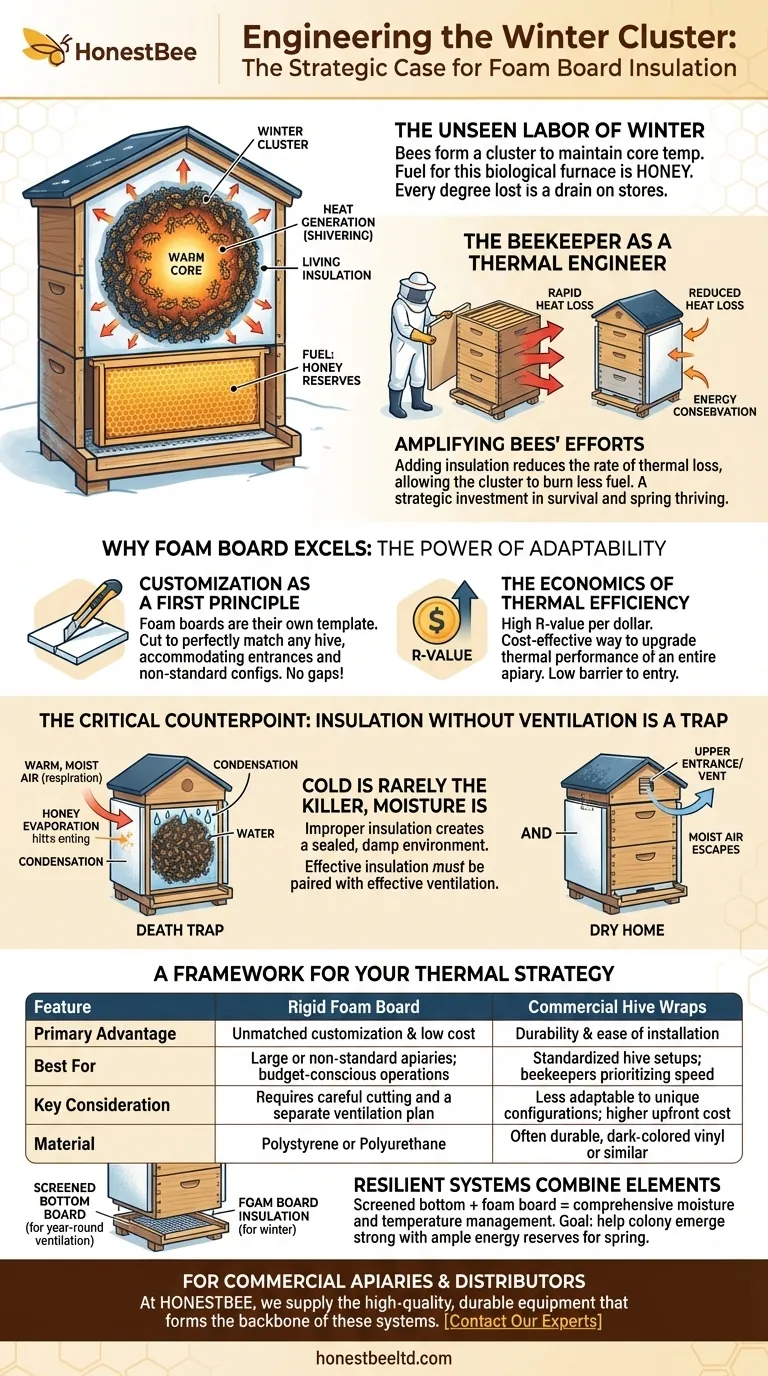

The Unseen Labor of Winter

Inside a beehive, as temperatures plummet, a silent, metabolic battle begins. The honey bee colony, a marvel of collective intelligence, forms a tight sphere—the winter cluster.

Bees on the inside shiver, vibrating their wing muscles not to fly, but to generate heat. Bees on the outside press together, creating a living blanket of insulation. Their goal is singular: maintain a core temperature warm enough to keep the queen and the colony alive.

This effort is immensely costly. The fuel for this biological furnace is honey—the colony's precious food reserve gathered over months of labor. Every degree of heat lost to the frigid air is a quantifiable drain on their winter stores. For the beekeeper, the central challenge isn't just to protect the bees from the cold, but to make their fight for survival more efficient.

The Beekeeper as a Thermal Engineer

A beekeeper’s intervention is a question of energy management. By adding insulation, you are not replacing the bees' efforts; you are amplifying them. You are reducing the rate of thermal loss, allowing the cluster to burn less fuel to achieve the same life-sustaining temperature.

This small change in the hive's thermal dynamics has an outsized impact on the colony's probability of not just surviving, but thriving into the spring. It's a strategic investment in energy conservation.

Why Foam Board Excels: The Power of Adaptability

While several insulation options exist, rigid foam board stands out for reasons rooted in practicality and engineering logic. It embodies a principle of ultimate adaptability.

Customization as a First Principle

No two apiaries, and often no two hives, are perfectly identical. Pre-made solutions assume a standard that rarely exists.

Foam boards, made of polystyrene or polyurethane, are their own template. They can be cut with a simple utility knife to perfectly match the dimensions of any hive body, accommodate upper entrances, or fit non-standard configurations. This precision ensures there are no gaps where heat can easily escape.

The Economics of Thermal Efficiency

In commercial operations, every input must be justified. Rigid foam insulation offers one of the highest R-values (a measure of thermal resistance) per dollar spent.

It's a widely available construction material, making it an exceptionally cost-effective way to upgrade the thermal performance of an entire apiary. This low barrier to entry allows beekeepers to implement a crucial survival strategy without a significant capital investment.

The Critical Counterpoint: Insulation Without Ventilation is a Trap

Herein lies the crucial insight often missed by novice beekeepers: cold is rarely the primary killer in winter. Moisture is.

A colony's respiration and the evaporation of honey release a significant amount of warm, moist air. When this air hits a cold inner surface, it condenses into water, which can drip down onto the cluster, chilling and killing the bees.

Foam board is an excellent insulator, but it is not breathable. Using it improperly can create a sealed, damp environment—a death trap.

Effective insulation, therefore, must be paired with effective ventilation. A small upper entrance or a slightly cracked inner cover allows this moist air to escape, keeping the hive interior dry. The goal is a warm, dry home, not a warm, wet one.

A Framework for Your Thermal Strategy

Choosing the right approach depends on balancing goals like cost, convenience, and performance.

| Feature | Rigid Foam Board | Commercial Hive Wraps |

|---|---|---|

| Primary Advantage | Unmatched customization & low cost | Durability & ease of installation |

| Best For | Large or non-standard apiaries; budget-conscious operations | Standardized hive setups; beekeepers prioritizing speed |

| Key Consideration | Requires careful cutting and a separate ventilation plan | Less adaptable to unique configurations; higher upfront cost |

| Material | Polystyrene or Polyurethane | Often durable, dark-colored vinyl or similar material |

Ultimately, the most resilient systems combine elements. Using a screened bottom board for year-round ventilation, combined with foam board insulation for winter, creates a comprehensive management system that addresses both moisture and temperature.

The goal is to help the colony emerge from winter not just alive, but strong, with ample energy reserves to begin the crucial work of spring buildup.

For commercial apiaries and distributors focused on building resilient, productive operations, having the right tools for thermal management is non-negotiable. At HONESTBEE, we supply the high-quality, durable equipment that forms the backbone of these systems. Contact Our Experts

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Inner Beehive Cover for Beekeeping Bee Hive Inner Cover

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Premium Comfort Grip Spring-Loaded Hive Handles

- Versatile Ratchet Hive Strap with S-Hooks for Secure Fastening

Related Articles

- How to Time Hive Insulation for Maximum Winter Bee Survival

- The Physics of Wintering: Why Condensation is a Beekeeper's True Enemy

- Comprehensive Guide to Attracting Bees to a Hive

- The Cold Deception: Why Beehive Wintering is About Moisture, Not Warmth

- The Silent Killer in the Hive: Why Moisture, Not Cold, Is Winter's Greatest Threat