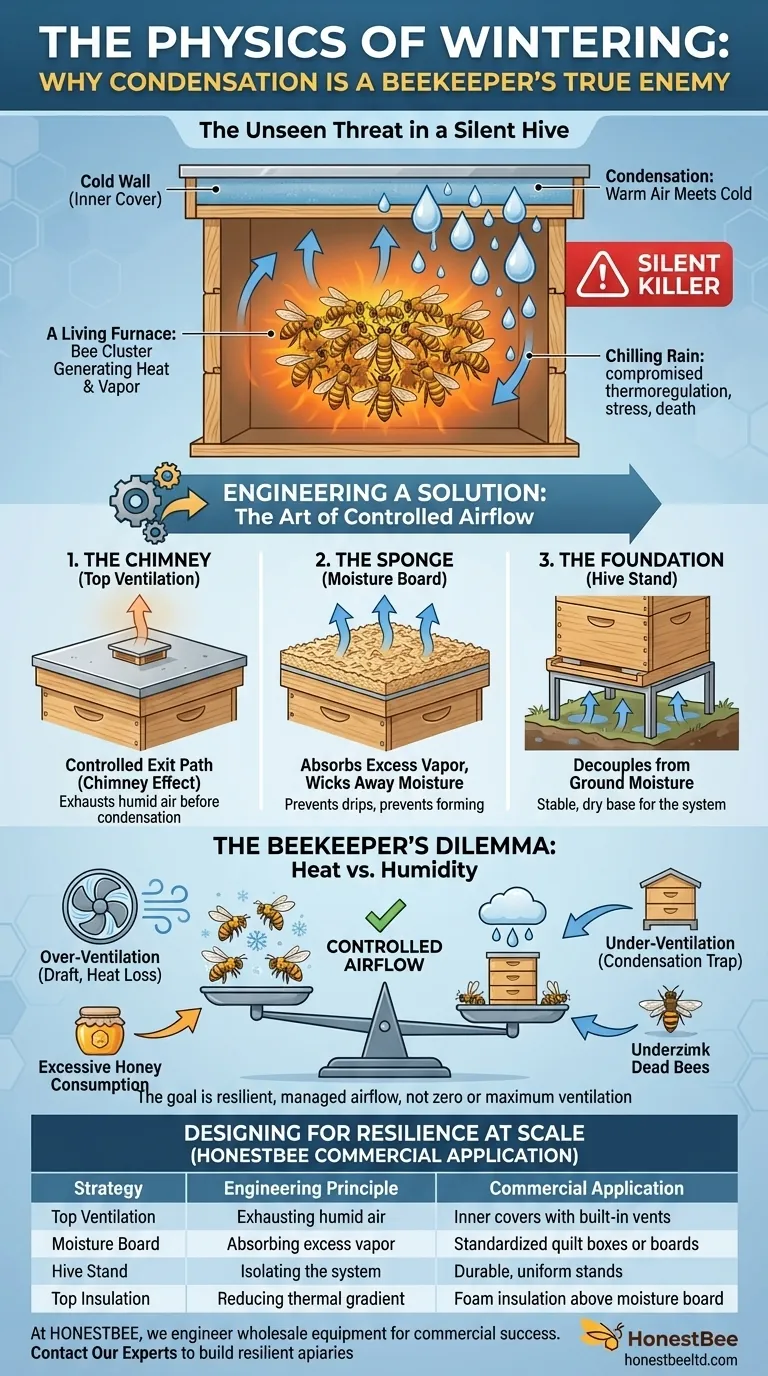

The Unseen Threat in a Silent Hive

Imagine walking through an apiary in the quiet cold of late winter. You open a hive, expecting to see a vibrant cluster, only to find the colony has perished. The honey stores are full, untouched. The bees didn't starve.

They were wet. Cold droplets of water on the inner cover tell the story.

The common mistake is to think the enemy was moisture. But the true culprit is a subtle, relentless law of physics: condensation. This is the silent killer, and understanding it is the difference between a thriving apiary and a devastating loss.

A Living Furnace in a Wooden Box

A winter bee cluster is a marvel of thermal regulation. By consuming honey, the bees metabolize sugar into energy, generating a significant amount of heat and water vapor.

This creates a bubble of warm, humid air—a microclimate essential for their survival.

The problem isn't that this air exists. The problem begins when this warm, life-sustaining vapor embarks on a short, vertical journey.

When Warm Air Meets a Cold Wall

As the warm, moist air rises, it eventually hits the cold inner surface of the hive cover. The temperature difference is a physical trigger. The air can no longer hold its water vapor.

It condenses, changing from a harmless gas into cold, liquid droplets.

These droplets then rain back down onto the very bees that produced the warmth. A wet bee cannot effectively thermoregulate. The colony's collective heating system is compromised, leading to chilling, stress, and eventually, death. They are defeated not by the external cold, but by a failure of their internal climate control.

Engineering a Solution: The Art of Controlled Airflow

To defeat condensation, you must think like an HVAC engineer, not just a beekeeper. Your goal is to design a system that allows harmful moisture to escape without sacrificing the essential warmth the bees worked so hard to create.

A multi-pronged strategy is the only reliable approach.

1. The Chimney: Top Ventilation

The simplest and most critical element is a small opening at the top of the hive.

This creates a "chimney effect." The warm, humid air, which naturally wants to rise, is given a controlled exit path before it can hit the cold lid and condense. This is not about creating a draft; it's about providing a deliberate exhaust port.

2. The Sponge: The Moisture Board

In many climates, ventilation alone is insufficient. A moisture board, often made of wood shavings or other absorbent material, is placed above the inner cover.

This board acts like a sponge, intercepting any rising water vapor that hasn't escaped through the vent. It traps the moisture, wicking it away from the bees and allowing it to dissipate slowly, preventing drips from ever forming.

3. The Foundation: The Hive Stand

A surprising amount of moisture doesn't come from the bees, but from the ground. A hive placed directly on damp earth will constantly wick moisture up through its bottom board.

A sturdy hive stand is non-negotiable. It elevates the colony, decoupling it from ground moisture and protecting it from rain splash-back. It creates a stable, dry foundation for the entire system.

The Beekeeper's Dilemma: Heat vs. Humidity

The core tension in winter hive management is balancing moisture removal with heat retention.

Over-ventilate, and you create a draft that forces the bees to burn through their honey stores just to stay warm. Under-ventilate, and you create the condensation trap.

The psychological trap for beekeepers is to focus on one threat at the expense of the other. The goal is not zero ventilation or maximum ventilation. The goal is controlled airflow.

Designing for Resilience at Scale

For commercial apiaries, managing this balance across hundreds or thousands of colonies isn't a hobby; it's a critical operational challenge. Guesswork leads to unacceptable losses. Success depends on reliable, standardized equipment that makes the right microclimate the default.

| Strategy | Engineering Principle | Commercial Application |

|---|---|---|

| Top Ventilation | Exhausting humid air | Using inner covers with built-in ventilation ports. |

| Moisture Board | Absorbing excess vapor | Implementing quilt boxes or moisture boards as standard winter gear. |

| Hive Stand | Isolating the system | Deploying durable, uniform stands to ensure every hive is protected. |

| Top Insulation | Reducing the thermal gradient | Adding foam insulation above the moisture board to keep the inner lid warmer. |

At HONESTBEE, we understand that a successful apiary is a well-engineered system. We supply the wholesale beekeeping equipment designed to manage these environmental pressures effectively. Our durable hive stands, moisture management systems, and ventilation components are built for the demands of commercial operations that can't afford to lose a single colony to a preventable physics problem.

To build resilient apiaries that master these environmental challenges, you need equipment designed for the task. Contact Our Experts

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Inner Beehive Cover for Beekeeping Bee Hive Inner Cover

- Professional Reversible Beehive Hive Entrance

- Multi-Functional Sliding Hive Entrance for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

Related Articles

- How to Time Hive Insulation for Maximum Winter Bee Survival

- Moisture, Not Cold: The Counterintuitive Physics of Wintering Bees

- The Quiet Interface: How a Simple Inner Cover Prevents a War in the Hive

- Engineering the Winter Cluster: The Strategic Case for Foam Board Insulation

- Winter Hive Management: To Open or Not to Open?