Modern beekeeping demands efficiency at every stage—from hive management to honey extraction. Among the most impactful innovations is the bee box-making machine, a specialized tool that streamlines frame production while reducing operational costs. This article explores how these machines enhance productivity across apiary scales, backed by practical insights for optimal performance.

Benefits of Bee Box-Making Machines

Reducing Labor Costs and Time in Frame Assembly

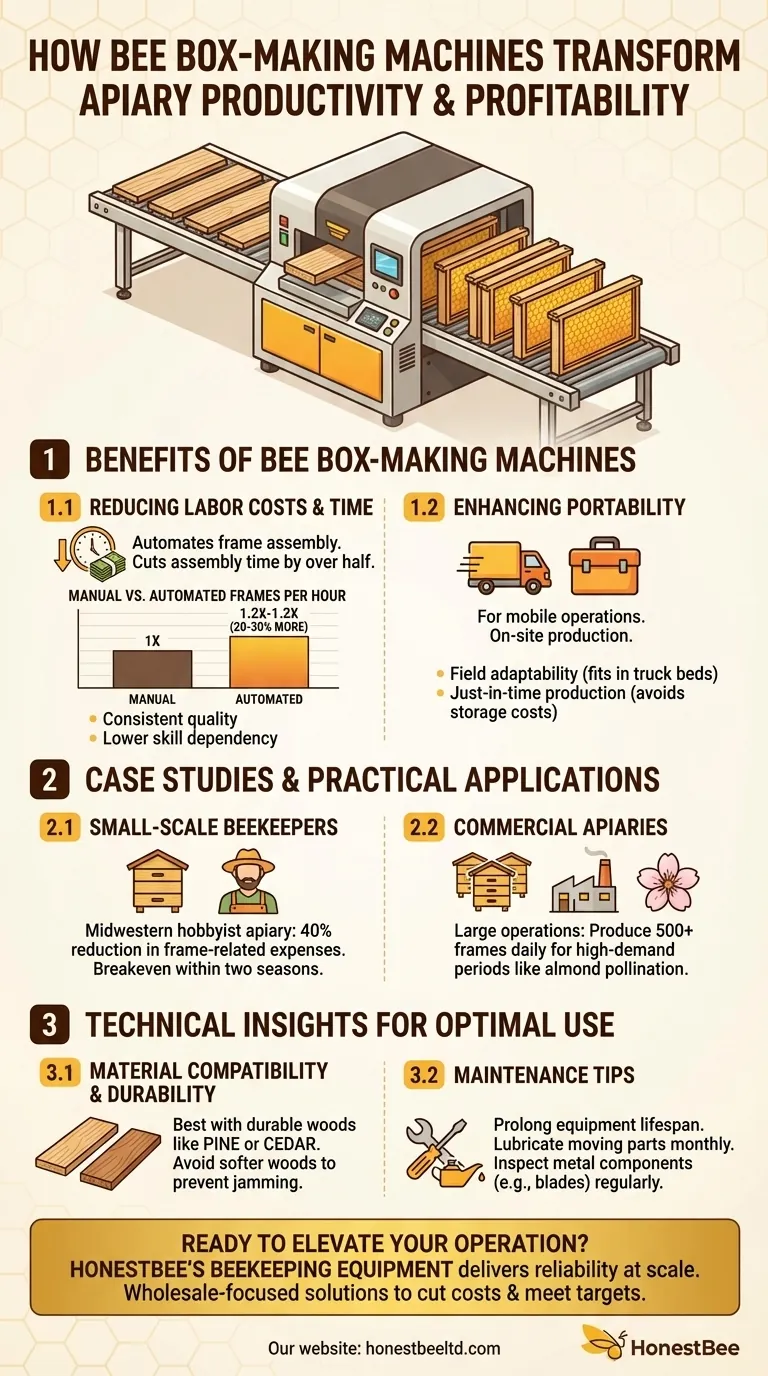

Traditional frame assembly is labor-intensive, requiring precise measurements and manual nailing. Bee box-making machines automate this process, cutting assembly time by over half. Research shows that automated systems allow beekeepers to produce 20–30% more frames per hour compared to manual methods.

Key advantages:

- Consistent quality: Machines ensure uniform frame dimensions, critical for hive health.

- Lower skill dependency: Reduces training needs for seasonal workers.

Enhancing Portability for Mobile Beekeeping Operations

For migratory beekeepers, transporting pre-assembled frames is cumbersome. Portable bee box-making machines enable on-site production, minimizing damage risks during transit.

Practical applications:

- Field adaptability: Lightweight models fit in truck beds for pollination contracts.

- Just-in-time production: Avoids storage costs for excess inventory.

Case Studies and Practical Applications

Small-Scale Beekeepers: Balancing Cost and Output

A midwestern hobbyist apiary reported a 40% reduction in frame-related expenses after investing in a compact machine. The breakeven point was achieved within two seasons through saved labor hours.

Commercial Apiaries: Scaling Production Sustainably

Large operations using industrial-grade machines can produce 500+ frames daily, meeting high-demand periods like almond pollination without outsourcing.

Technical Insights for Optimal Use

Material Compatibility and Machine Durability

Most machines accommodate pine or cedar—the two most durable woods for hive components. Avoid softer woods to prevent jamming.

Maintenance Tips to Prolong Equipment Lifespan

Regular upkeep prevents downtime:

- Lubricate moving parts monthly to reduce wear.

- Inspect metal components (e.g., cutting blades) for rust or damage, replacing them as needed—similar to maintaining mason jar bee feeders.

Ready to Elevate Your Beekeeping Operation?

For commercial apiaries and distributors, HONESTBEE’s beekeeping equipment delivers reliability at scale. Our wholesale-focused solutions help you cut costs while meeting production targets—because efficiency shouldn’t come at the expense of quality.

Explore how our tools can streamline your workflow today.

Visual Guide

Related Products

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Professional Pneumatic Wire Embedder for Beehive Frames

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

Related Articles

- Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization

- How Bee Box-Making Machines Transform Beekeeping Efficiency and Sustainability