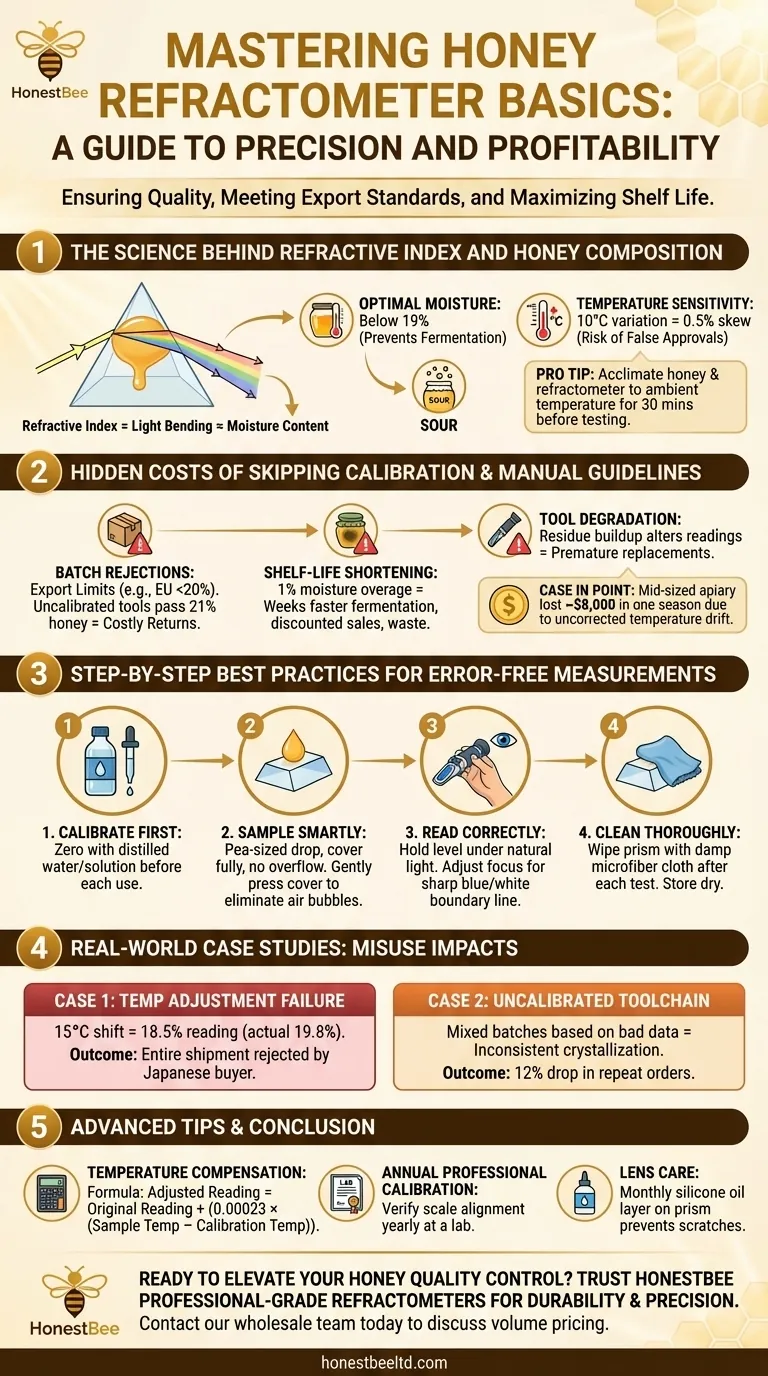

For commercial beekeepers and honey producers, ensuring product quality isn’t just about taste—it’s about meeting strict export standards, avoiding costly rejections, and maximizing shelf life. A honey refractometer is your frontline defense against fermentation, crystallization, and non-compliant moisture levels. Yet, improper use can lead to measurement errors that ripple through your entire operation. This guide demystifies refractometer fundamentals, helping you avoid common pitfalls while unlocking consistent, market-ready honey quality.

The Science Behind Refractive Index and Honey Composition

Honey’s refractive index—a measure of how light bends as it passes through the substance—directly correlates with its moisture content. Research shows that:

- Optimal moisture levels (typically below 19%) prevent fermentation, a key concern for exporters.

- Temperature sensitivity: A 10°C variation can skew readings by up to 0.5%, risking false approvals of borderline batches.

Why does this matter? High-moisture honey ferments faster, creating gas bubbles and sour flavors that render it unsellable. By contrast, overly dry honey (below 15%) may crystallize prematurely, reducing its market appeal.

Pro Tip: Always let your honey and refractometer acclimate to the same ambient temperature for 30 minutes before testing.

Hidden Costs of Skipping Calibration and Manual Guidelines

Neglecting refractometer maintenance isn’t just a technical oversight—it’s a financial liability. Consider these real-world consequences:

- Batch Rejections: Export markets like the EU enforce strict moisture limits (under 20%). Uncalibrated tools may falsely pass honey at 21%, leading to costly returns.

- Shelf-Life Shortening: Even a 1% moisture overage can accelerate fermentation by weeks, forcing discounted sales or waste.

- Tool Degradation: Residue buildup from incomplete cleaning alters future readings, requiring premature replacements.

Case in Point: A mid-sized apiary lost nearly $8,000 in a single season due to uncorrected temperature drift in their refractometer readings.

Step-by-Step Best Practices for Error-Free Measurements

Follow this field-tested protocol to ensure consistent accuracy:

-

Calibrate First

- Use distilled water or a calibration solution to zero the refractometer before each use.

-

Sample Smartly

- Apply a pea-sized honey drop to fully cover the prism without overflow.

- Gently press the cover plate to eliminate air bubbles—these scatter light and distort readings.

-

Read Correctly

- Hold the refractometer level under natural light.

- Adjust the focus until the boundary line between blue and white is sharp.

-

Clean Thoroughly

- Wipe the prism with a damp microfiber cloth after each test; avoid abrasive materials.

Remember: Store your refractometer in a dry, temperature-stable environment to prevent internal condensation.

Real-World Case Studies: How Misuse Impacts Commercial Outcomes

Case 1: The Overlooked Temperature Adjustment

A Texas honey co-op failed to account for a 15°C warehouse-to-field temperature shift during summer harvests. Their refractometer reported 18.5% moisture, but lab tests revealed actual levels at 19.8%—triggering an entire shipment’s rejection by a Japanese buyer.

Case 2: The Uncalibrated Toolchain

An Australian distributor mixed honey batches based on uncalibrated refractometer data, resulting in inconsistent crystallization rates across retail jars. Customer complaints led to a 12% drop in repeat orders.

Lesson: Regular calibration and environmental awareness aren’t optional—they’re profit protectors.

Advanced Tips: Temperature Adjustments and Long-Term Tool Maintenance

For precision beyond basics:

- Temperature Compensation: If testing in varying conditions, use the formula:

Adjusted Reading = Original Reading + (0.00023 × (Sample Temp – Calibration Temp)). - Annual Professional Calibration: Even with careful use, send your refractometer to a lab yearly to verify its scale alignment.

- Lens Care: Apply a thin layer of silicone oil to the prism monthly to prevent scratches from granulated honey samples.

Ready to Elevate Your Honey Quality Control?

HONESTBEE’s professional-grade refractometers are trusted by commercial apiaries worldwide for their durability and precision. Pair yours with our beekeeping equipment to streamline your workflow from hive to export. Contact our wholesale team today to discuss volume pricing and industry-specific solutions.

Final Thought: In honey production, every decimal point in moisture content translates to dollars earned—or lost. Mastering your refractometer isn’t just about measurements; it’s about measurable business success.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- The Unseen Architecture of Trust: Calibrating the Honey Refractometer

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery

- The Second Half of the Measurement: Protecting the Integrity of Your Honey Refractometer

- How to Accurately Test Honey Readiness: Science-Backed Methods for Beekeepers

- The Professional’s Guide to Honey Refractometer Calibration: Ensuring Quality, Protecting Profit